Trustworthy Solventless Laminating Machine Manufacturer

The solventless machine adopts a method that can composite two or more substrates by using solvent-free adhesives. The solventless composite process begins in Germany in the 1970s. The solventless laminating machine has a wide application with the advantages of environmental, hygiene, and high efficiency, especially used for the packaging industry of the food and the drug.

Development Of Solventless Laminating Machine

In 1974, the German company adopts the single component solventless-free adhesive in industrial production, marking the formal promotion of solvent-free composite.

In the 1980s, there was rapid development in developed countries such as Europe and the United States.

At the end of the 1990s, Japan gradually began to play an important to no solvent composite and had a great development. In India, Russia, Brazil, the solventless composite has gradually become the leading composite process.

In 1985, China had introduced the production technology and equipment of the solvent-free polyurethane adhesive from Germany, thereby enters the era of solventless composite process.

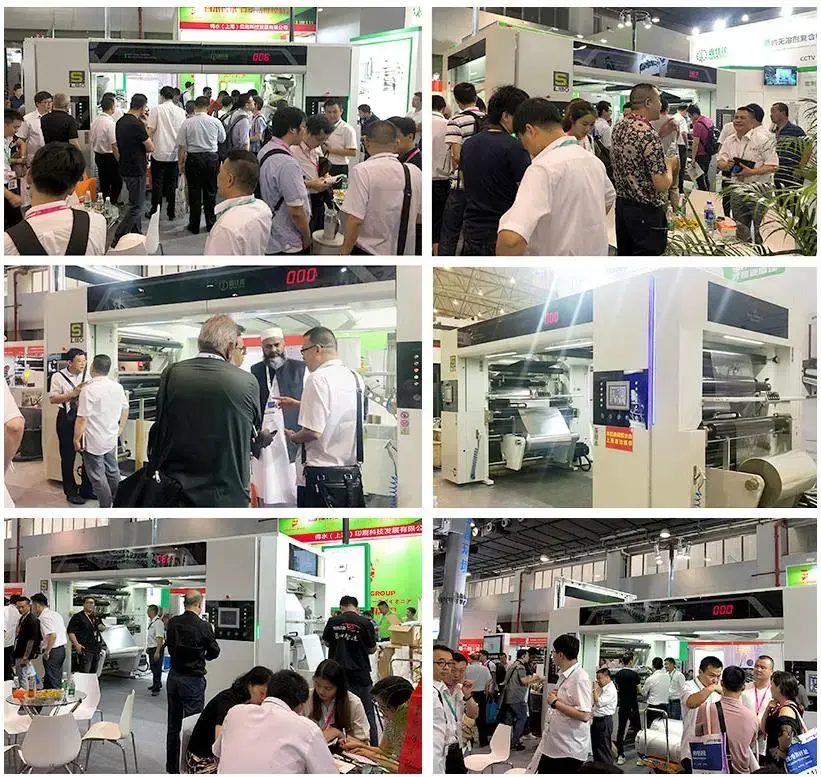

Competitive Solventless Laminating Machine Manufacturer In China – Sinstar

Sinstar, which is the abbreviation of Sinstar Packaging Machinery Co., Ltd, was founded in 2005. It is a professional company which focused on the R & D, production, sales and service of a solventless laminating machine. It is located in the National High-tech Industrial Park, Rongchang District, Chongqing, with an annual production capacity of 200 sets. Since its establishment, the company has characterized simple-operate, safety, high durability and perfect service. Sinstar has become one of the most competitive solventless laminating machine manufacturers in China.

Solventless lamination machine supplied by Sinstar, has independent innovation patented technology, including “CCMS coated clearance memory system”; “FGPS foolproof glue preparation system”; “precision metering control system”; “coating weight directly inputting system”, “ratio pressure protection system” “quick cleaning system”, “zero error tension control system”, etc.

Sinstar has 135 authorized patents, including 7 authorized invention patents, 123 utility model patents, 5 appearance design patents. Sinstar is devoted to providing green and environmentally friendly solventless composite packaging machinery, technical guaranteeing the safety of food and drug packaging.

Mainly Solventless Laminating Machine Types Of Sinstar

Now Sinstar has several series of solventless laminating machines, including the series of WRJSi9, WRJi9, WRJFi9, SIL90, WRJSLi5, C180, E280, S380. Compared with the single station solventless laminating machine, the double station type mainly has the following advantages.

WRJSi9

On June 8, 2021, Sinstar has launched a new product – three-layer solventless laminator and machine model is WRJSi9.

Three-layer composite machines, as the name implies is a solventless machine realizing one-time composite forming of three-layer materials. In recent years, there is a high-speed development for solventless composite, and the requirements for composite process and equipment functions are increasing. The solventless lamination equipment which can carry out the substrates compounding of multi-layer materials on a composite machine, is in urgent need.

Sinstar three-layer solventless machine has a reasonable structural layout, simple loading, saving time and effort, realizing one-time molding for three-layer composite, which is beneficial to improve production efficiency and product quality.

Advantages

1. Simple and convenient to load

2.Shorten the delivery term

3.Increase productivity

4. Greatly reduces the labor intensity of employees

5.Save electricity energy

6. Easy to operate

S1L90 Series

The S1L90 series rational solventless laminator includes models of S1L90-1000A, S1L90-1300A, S1L90-1600A.

Features

1. Combination of ergonomics &green packaging technology

2.Redefining tension(Rational tension)

3.Farewell to sensuous tension(Tactile tension)

4.Same tension at high and low speeds

5.Digital tension system

6. External roll-diameter status display

WRJ i9 Series

The WRJ i9 Series solventless machine includes models of WRJ i9-1000A, WRJ i9-1300A, WRJ i9-1600A.

Advanced systems

CWDS: Coating Weight Directly Inputting system

MRPS: Multiple Ratio Protection System

CCMS: Coating Clearance Memorizing System

FCS: Fast Cleaning System

PCWD: Precise Coating Weight Detecting system

WRJF i9 Series

The WRJ i9 Series solventless lamination machine includes models of WRJF i9-1000A, WRJF i9-1300A, WRJF i9-1600A.

Characteristics

1. Simple Operation.

2. Automatic analyzing.

3. One-button multiple-points position system.

4. High viscosity glue feeding and coating applicable.

5. Accurate swinging arm tension to control aluminum foil movement.

6. Active unwinding for aluminum foil through motor control.

Summary

The solventless laminating machine for flexible packaging industry has good performance, green environmentally friendly, low energy consumption, no residual solvent and high precise coating. Sinstar is your trustworthy solventless laminating machine manufacturer with various types of products including the series of WRJSi9, WRJi9, WRJFi9, SIL90, WRJSLi5, etc. The Sinstar solvent-free machine has advanced systems, easy-to-operate, high safety, high efficiency and long service life.