Blogs

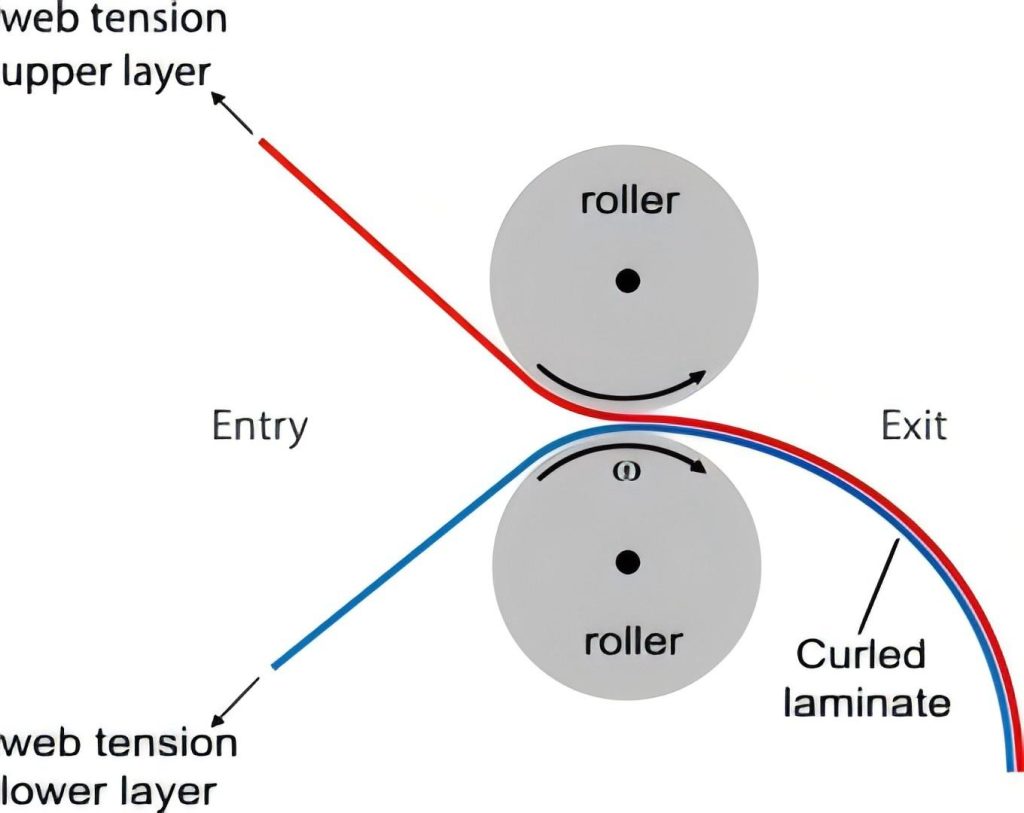

Mastering Web Tension in Solventless Lamination Machines for Defect-Free Packaging

In today’s flexible packaging industry, the solventless lamination process has become the preferred solution for manufacturers seeking higher efficiency, lower VOC emissions, and improved sustainability. However, while solventless technology eliminates solvent drying systems, it significantly increases sensitivity to one critical parameter:…

Why Are More Liquid Food Manufacturers Choosing Flexible Pouches?

The liquid food industry has experienced a major transformation during the last few years. Flexible pouches have become the new standard for packaging products that used to require glass bottles and rigid plastic containers and metal cans. The format is now…

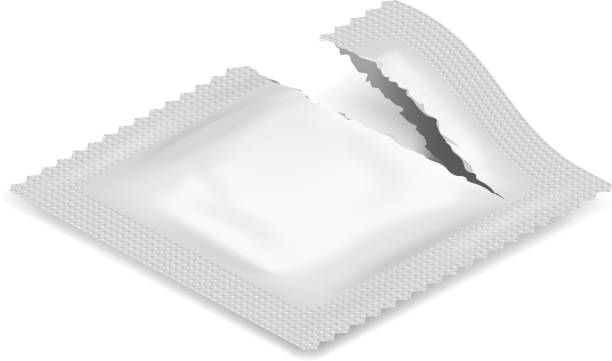

Why Film Delamination Happens and How Lamination Machines Solve It?

In flexible packaging and industrial film applications, delamination is one of the most common and most frustrating quality problems. A film that looks fine on the surface may start to peel, blister, or separate between layers during use. Once that…

SunLam QA-8000+HA450: High-Performance ULM Solventless Adhesive for Laminates

Sun Chemical showed off their newest eco-friendly packaging technology in early 2026: the SunLam QA-8000+HA450 solventless adhesive. This new adhesive uses ultra-low monomer (ULM) technology, which is a big step forward in solventless lamination. It works better than any other glue…

EU PPWR 2025/40 Guide for Solventless Lamination Adhesives

Every manufacturer prefers solventless lamination adhesive as it is more suitable for eco-friendly food hybrid packaging. It is very environmentally sustainable as well as high-powered, leading to a preference for producers who wish to lower the levels of volatile organic compound…

Solventless Laminators in Pharmaceutical Packaging: Applications, Benefits & Trends

Decadently, the pharmaceutical packaging industry is experiencing a sea of change occasioned by stringent safety measures, growing sustainability outlooks, and the increased need for high performance flexible packaging. The solventless laminator is one of the most notable advances. Initially started for…

How Anti-Counterfeiting Packaging Protects Your Brands and Consumers?

In the context of an increasingly complex global supply chain, counterfeit products have no longer been a problem confined to a few industries. Domains such as cosmetics, food and beverages, medicine, and clothing accessories have all been affected to varying…

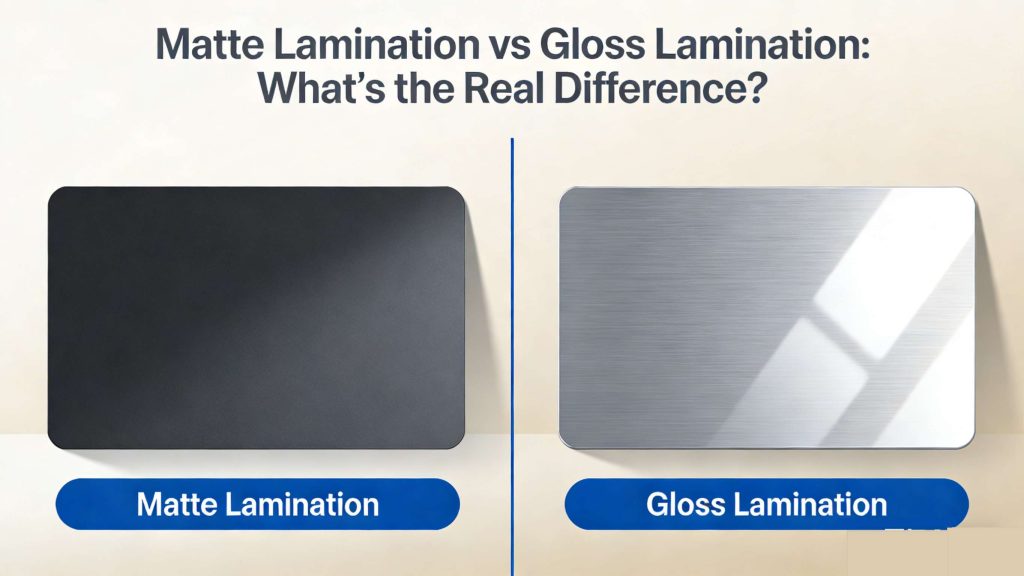

Matte Lamination vs Gloss Lamination: What’s the Real Difference?

In the printing and packaging industry, laminating is a common and important process. It not only protects paper and packaging materials from scratches, stains and moisture, but also enhances the overall visual effect, making the products look more refined and…