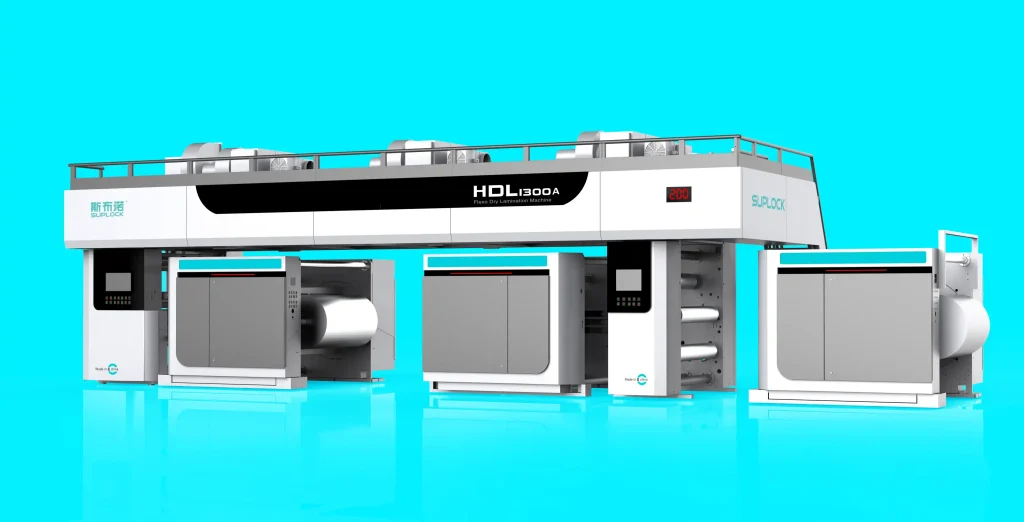

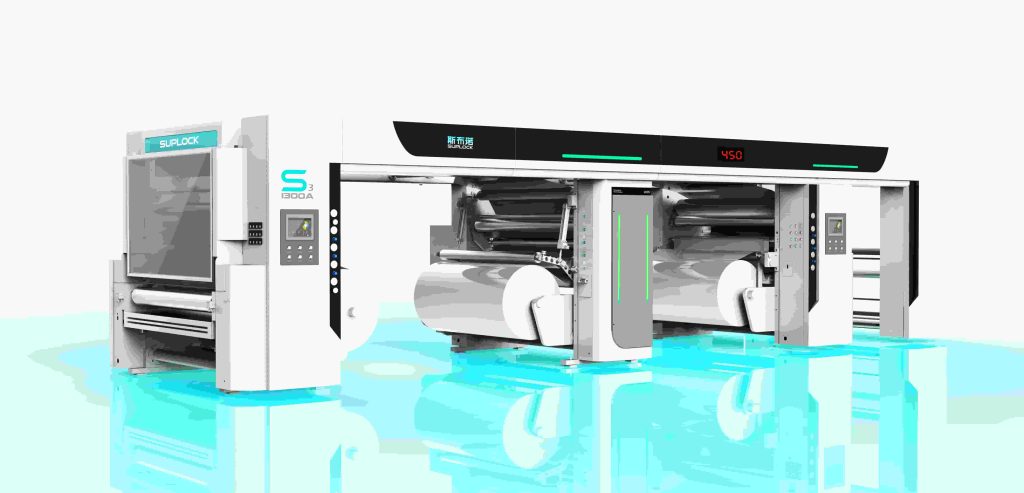

S1-1300A digital solventless laminating machine

The S1-1300A digital solventless laminating machine is a high-end product of the Suplock series under Sinstar, specially designed as a flexible packaging lamination machine for large-scale companies. As an expert flexible packaging laminating machine, it can perform high-quality laminating processing on various plastic films, aluminum-coated films, aluminum foil and paper.

S1 works efficiently with advanced laminating adhesives for flexible packaging to ensure uniform and stable laminating effects.

Features of S1-1300A Digital Solventless Laminator

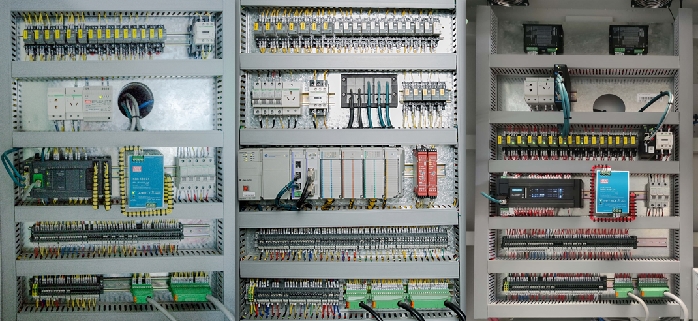

Equipped with an advanced digital control system, it can not only manage up to 300 sets of work orders, but also precisely control parameters such as temperature, pressure and speed, ensuring the stable quality and uniform thickness of composite materials. It can reach up to 500m/min, meeting the demands of large-scale production and enhancing production efficiency.

The core components are selected from key parts of international renowned brands, featuring high reliability and long service life.

Traditional laminating machines typically use solvent-based adhesives, while digital solvent-free laminating machines employ hot-melt or pressure-sensitive adhesives, eliminating the need for organic solvents and reducing the emission of harmful gases, thus meeting modern environmental protection standards.

Specification of S1-1300A Digital Solventless Laminator

| Maximum laminate speed | 500 m/m |

| Maximum laminate width | 1350 mm |

| Maximum unwinding diameter | 800 mm |

| Maximum rewinding diameter | 1000 mm |

| Material loading mechanism | shaftless loading |

| Core | 3+6 inch |

More Details

Related Solventless Laminators

Get Free Quote

Please fill in the following form, we will respond your request in 24 hours.