SINSTAR

Since 2005. SINSTAR has been focusing on laminator for

20 years, SINSTAR has been ranking No. 1 for years in Chinese market.

Company Profile

Established in 2005, Sinstar is located in Rongchang District, Chongqing City, and focuses on the research, development, production, sales and service of lamination equipments, obtaining the titles of “specialized and special new enterprises”, “high-tech enterprises”, “Chongqing gazelle enterprises”. Currently Sinstar has 2 factories, R & D and production area is about 30,000 square meters, including R & D center about 4,000 square meters. Our annual production capacity has exceed 400 units.

Main brands include: SINSTAR, SUPLOCK, Megaohmn, Outdry, Radiant UVLED, ACURATIO. The company’s production equipment has been successfully applied in 45 types of industries such as food packaging, pharmaceutical packaging, insulation materials, civil explosive packaging, sanitary packaging materials, waterproof materials, thermal insulation materials, label industry, industrial products, wires and cables, etc., and by the end of June 2025, more than 2680+ equipment have been put into use. Sinstar company has 4 international valid patents; 200+ domestic valid patents (more than 30 inventions, more than 160 practical patents, 14 appearances patents); 6 computer software works. The company’s team participated in the drafting and revision of GB/T 34150-2017 “Printing Machinery – Web Solvent-free Laminating Machine” and 6 group standards. Among them, the MegaOhmn insulating material composite machine MO-1300A was selected as the first (set) new product of major technical equipment in the country in 2023, and was recognized as the “first (set) major technical equipment in the country”.

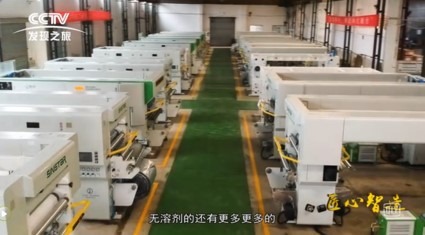

At present, Sinstar has two factories, Factory One and Factory Two. The production area of Factory One is approximately 6,000 square meters, while Factory Two about 20,000 square meters, the R&D center is about 4,000 square meters, and the total usable area is approximately 30,000 square meters. Annual production capacity exceeds over 300 units

Factory

Customers

Our clients include Amcor, Ansell, Xin’an (Guangzhou Secure Packaging), Duolianxi, Sichuan Yongzhi, Qingdao Haide, etc.

Sinstar is a multi-brand group company

innovation History

2005

company is established

2010

WRJ 10 solventless laminator

2013

WRJ 13 solventless laminator

2015

WRJ i5 solventless laminator

2016

WRJ Fi5 solventless laminator

2017

C180/280/380 fast solventless laminator

2018

S1L90/Fi9/i9 solventless laminator

2019

S2 dual-station solventless laminator

2020

S2 dual-station solventless laminator

2021

S1 solventless laminator

2022

MO insulation laminator

2023

TRI and S3 triplex laminator

2024

S3-1300A2 triplex laminator

2025

Advantages

Market share ranks No.1 in China

Sinstar ranks No.1 in the market share of solventless laminating machine in China. Focusing on solventless laminating machine for 20 years, we currently have more than 2680+ equipments being used in customers’ factories, and our products have been sold to 38 foreign countries, favored by the flexible packaging industry for its simple operation.

The main advantage of ours is

simple operation, which is highly favored by customers. For example: We pioneered to develop the direct input method for coating weight and one-click glue ratio verification. measurement intermittent one-click opening and closing technology; completing the setting of winding taper by one parameter; high-precision tension control technology

About Innovation

All the technological innovations of Sinstar are based on simple operation and are aimed at solving problems in the flexible packaging industry; We rank No.1 in China’s market share with an installed capacity of 2680+, which is the best evidence!

About Service

Sinstar’s team is composed of packaging process engineers, mechanical engineers, software engineers, and after-sales service engineers. No matter what innovative requirements you have, we can provide you with solutions in the shortest time. Meanwhile, each of our devices is equipped with remote IOT services.

Factory and Inspection

We have 8 production workshops with a production area of 30,000 square meters. Meanwhile, we have a professional QC team to ensure that the quality of the equipment we produce meets the design standards

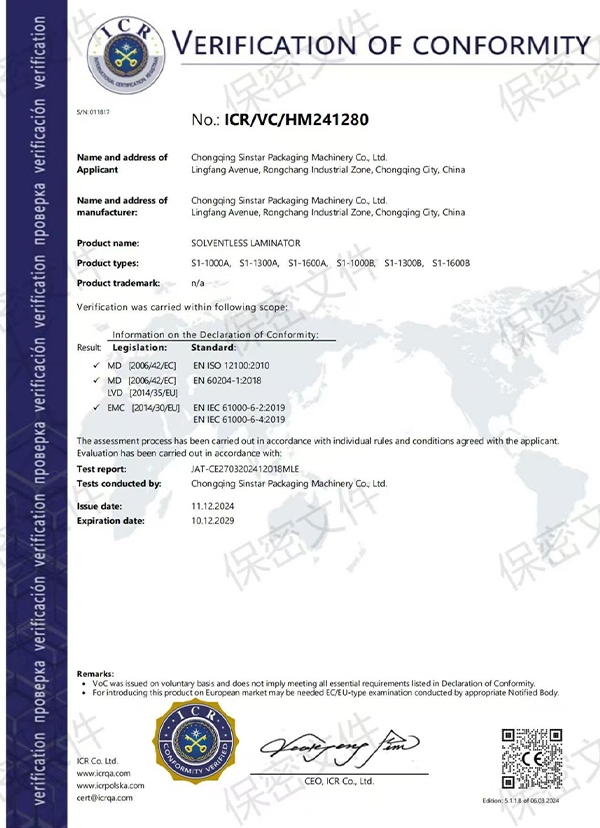

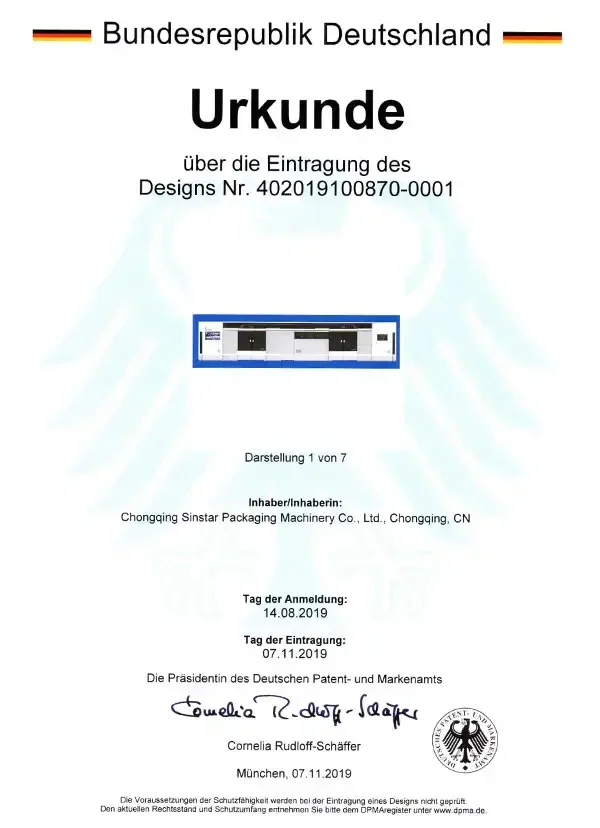

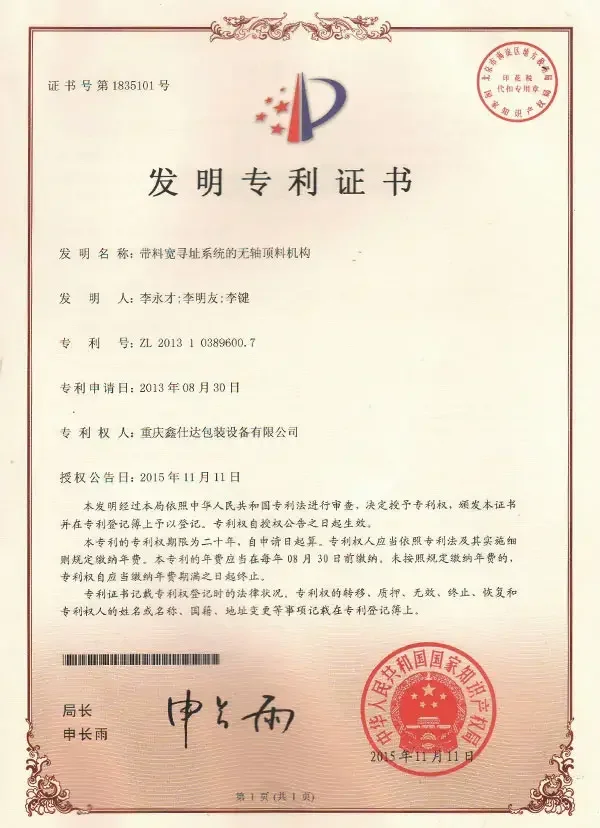

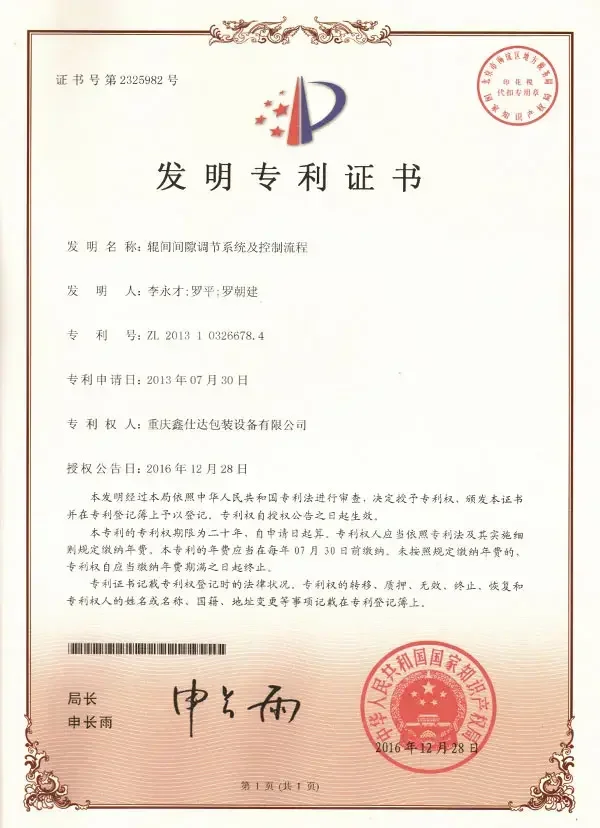

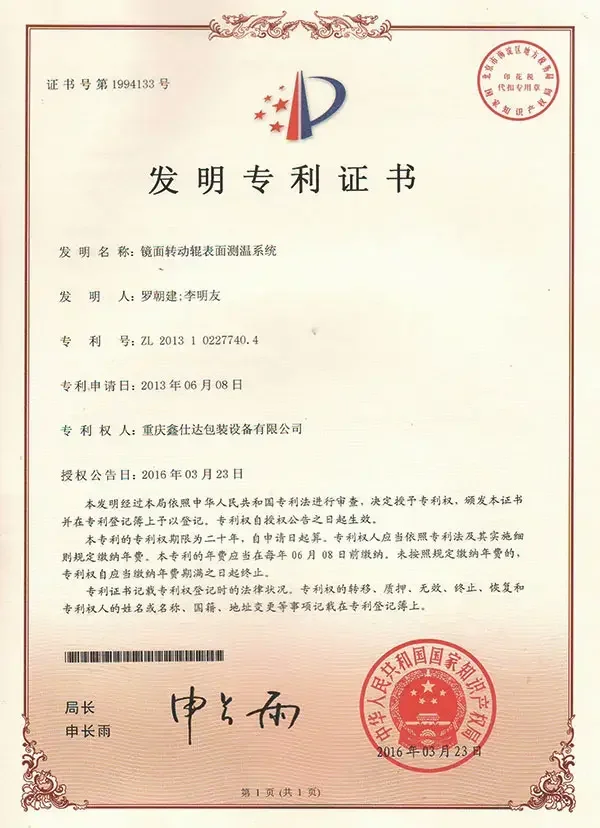

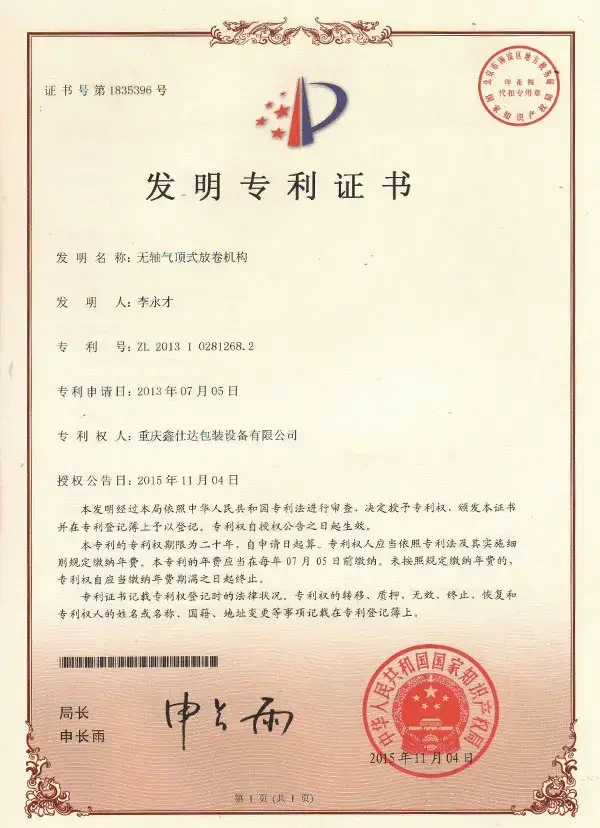

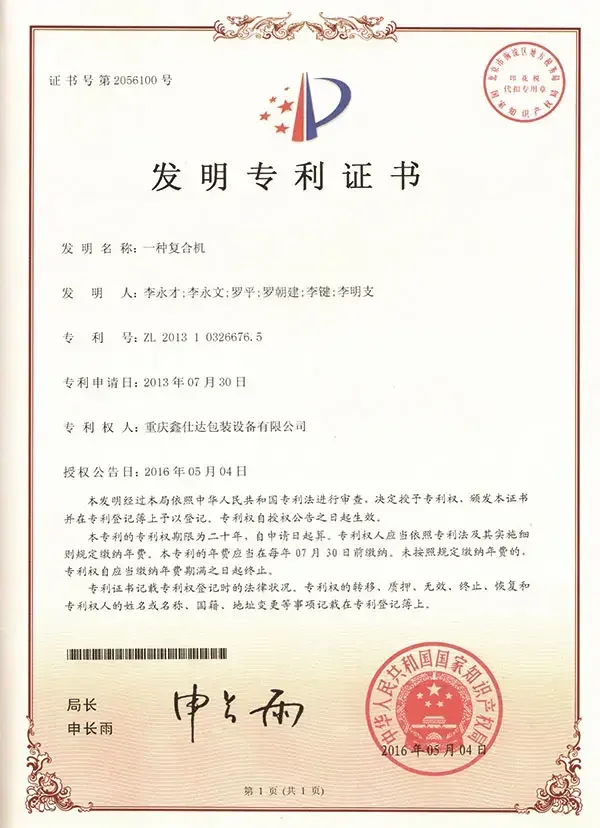

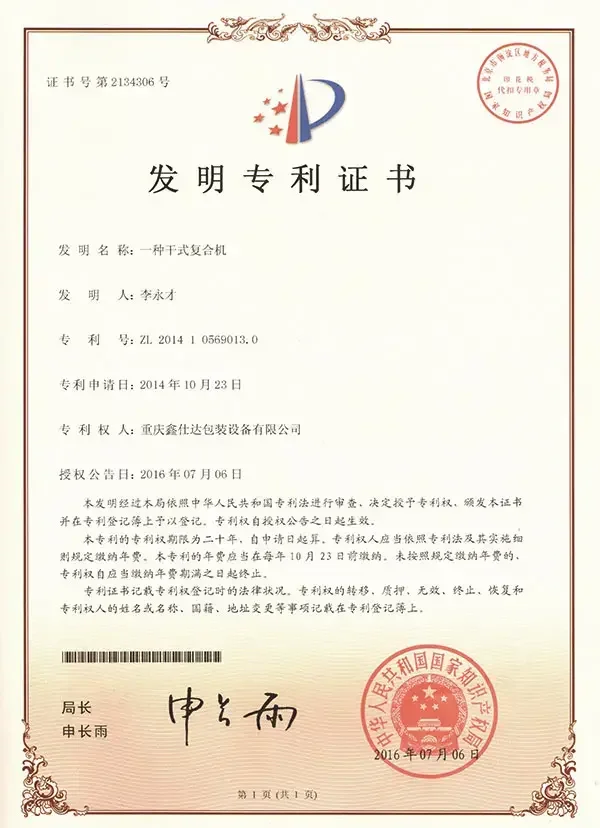

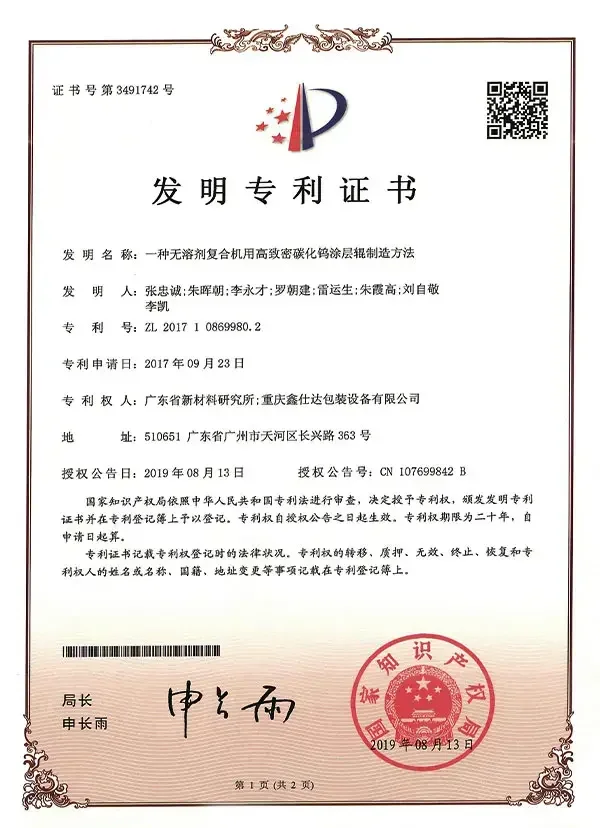

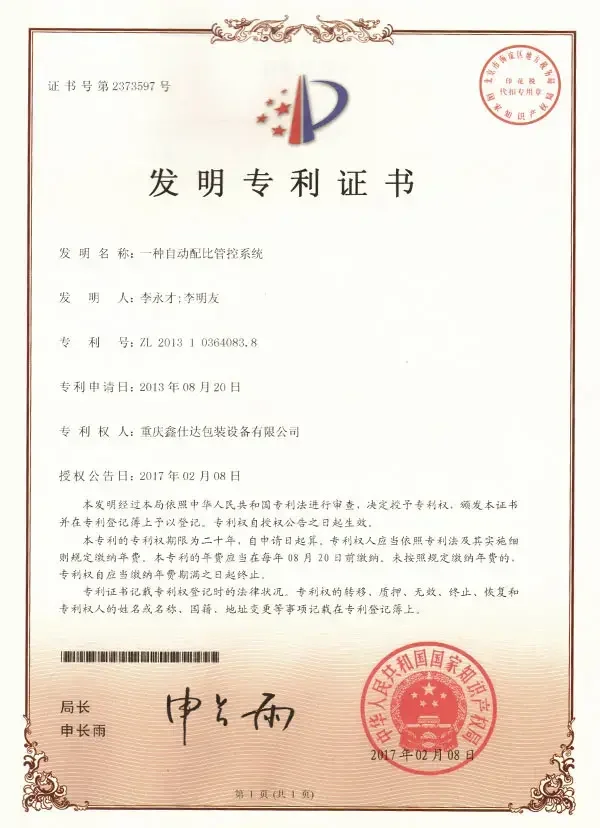

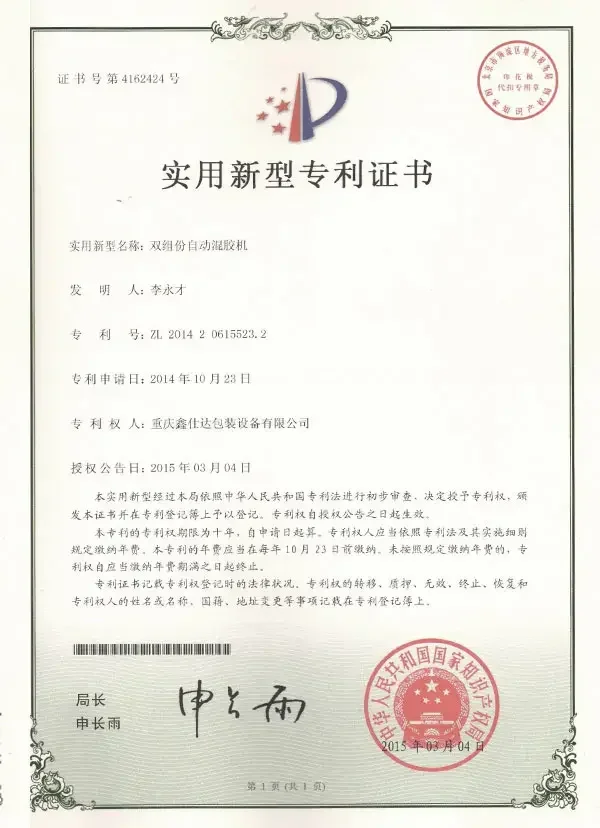

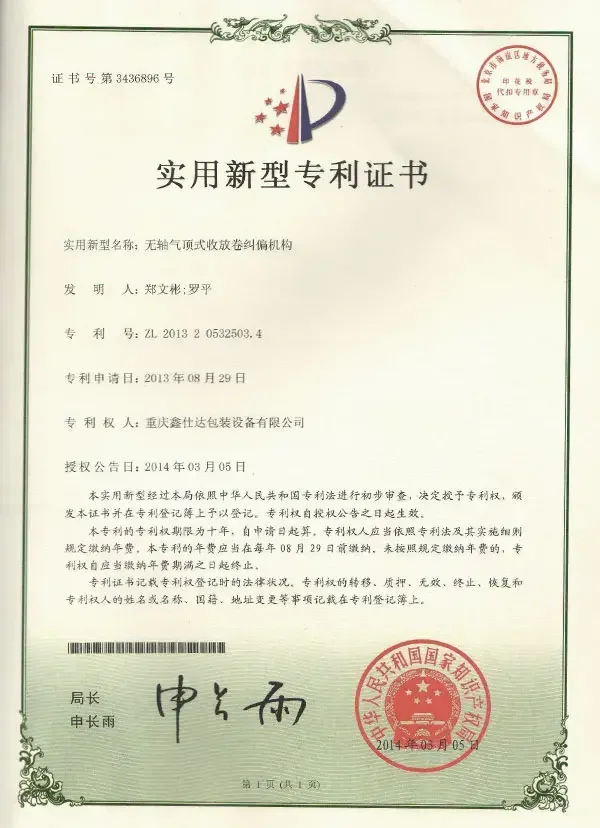

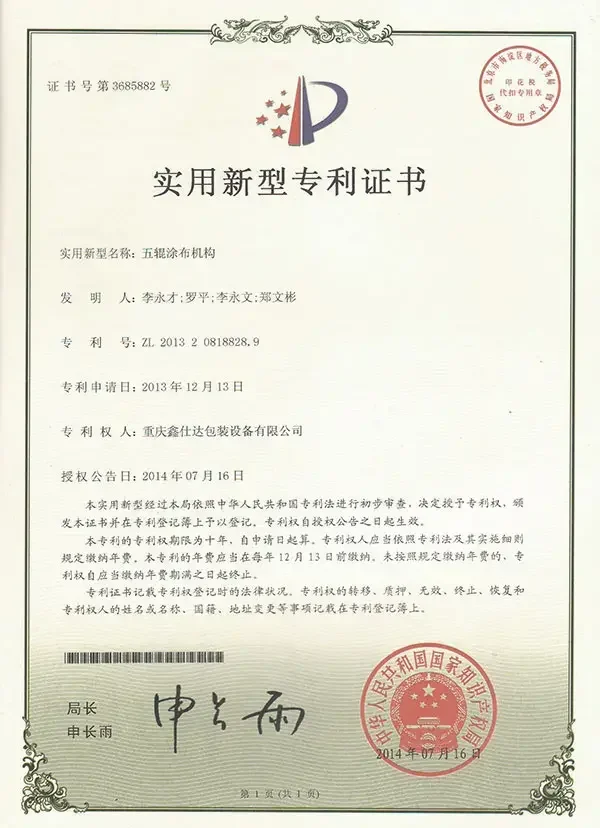

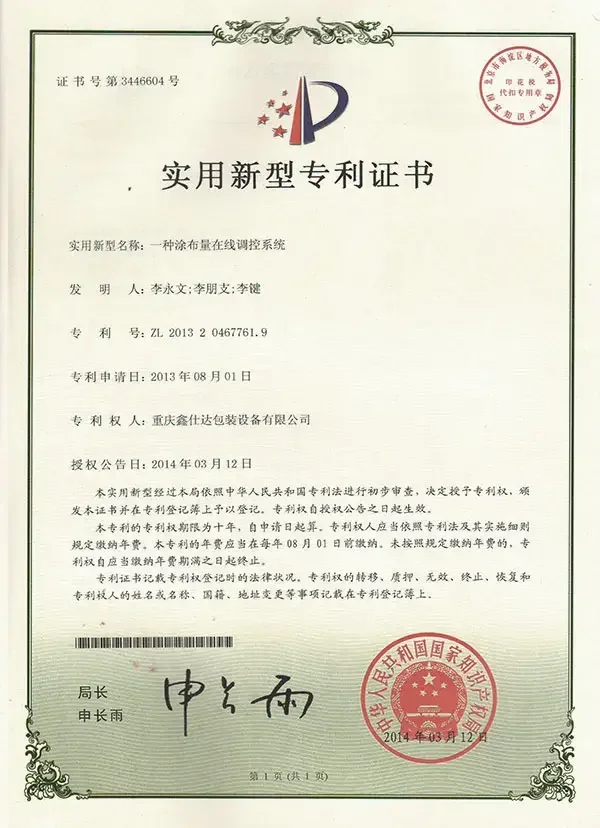

Certificate

S1 solventless laminator CE cerficate

5-2 glue mixer CE cerficate

S1L90 German appearance patent

S2L90 German appearance patent

Shaftless ejector mechanism with material payment addressing system

Gap adjustment system and control process between rolls

Mirror surface rotating roller surface temperature measurement system

Shaftless air top unwinding mechanism

A compound machine

Dry type compound machine

A manufacturing method of high density WC coated roller for solventless laminating machine

An automatic ratio control system

E280

S1L90

S380

Complex Machine

glue mixer

Solventless Laminating Machine

Winding device with linear cutter

Rational tension control system

Two-component automatic glue mixing machine

Shaftless air top type retracting and unwinding rewinding correction mechanism

Five-roll coating mechanism

A coating mechanism

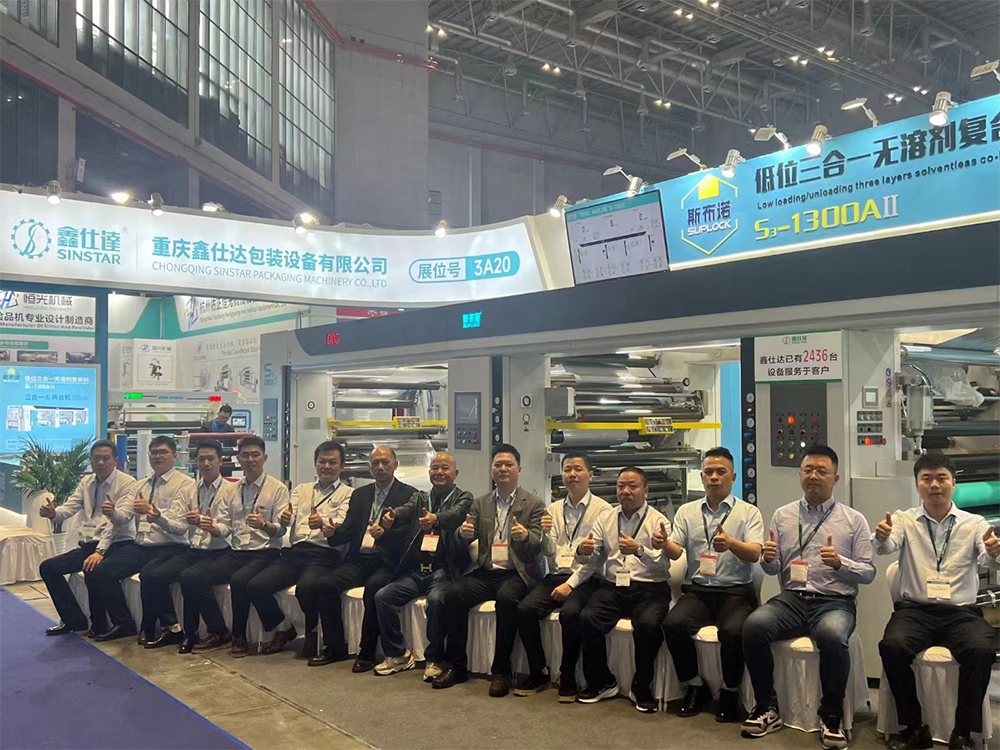

Exhibition

2025.01.14-2025. 01.16 GULF PRINT&PACK 2025

2025.4.15 CHINAPLAS 2025

2025.4.15 CHINAPLAS 2025

2024.11.20 Indonesia INDOPACKPRINT 2024

2024.9.18 Vietnam Print Pack 2024

2024.9.10Nigeria PRO-PLAS West Africa

2024.5.28 Drupa exhibtion

2024.4.23 CHINAPLAS 2024

2024.1.24 International Plastics Printing Packaging Industry Fair

2024.1.9 Dubai Gulf Print Pack

Laboratory room

The laboratory is mainly used for conducting comprehensive inspections of products and various indicators to provide scientific and reliable data support for inspection results.