TRI-1300A triplex solventless laminating machine

The TRI Triplex solvent-free laminating machine adopts a three-layer structure design and can laminate plastics, metal films, aluminum foil and paper quickly and efficiently, winning strong market recognition.

Compatible with a wide range of substrates:

For processing plastic films (such as PET, BOPP, and CPP), metallized films, aluminum foil, and paper.

Introduction

Triplex refers to 3-ply lamination. Compared with Duplex, Triplex can complete the lamination of three materials in one process, including common food or pharmaceutical packaging such as PET/AL/PE, BOPP/NY/CPP, etc. It is a highly efficient and environmentally friendly device that can complete the solvent-free lamination of a three-layer structure in one step, widely used in the production of high-end flexible packaging.

Main Advantages

- Lamination Quality: Resolved the effect of pinholes in 006 aluminum foil on the lamination process, ensuring smoother lamination. It has a good solution to the reverse osmosis/back osmosis adhesive problem in aluminum foil lamination, reducing defects through one-piece molding of intermediate layer lamination.

- Higher Production Efficiency: Triplex (three-layer) system delivers up to 3× faster lamination compared to duplex systems.

- Power Saving: It saves 90,000 kWh per year compared with similar equipment.

- The integrated three-layer composite process can replace two or more single-layer/double-layer machine equipment, reducing the production site space by approximately 40%.

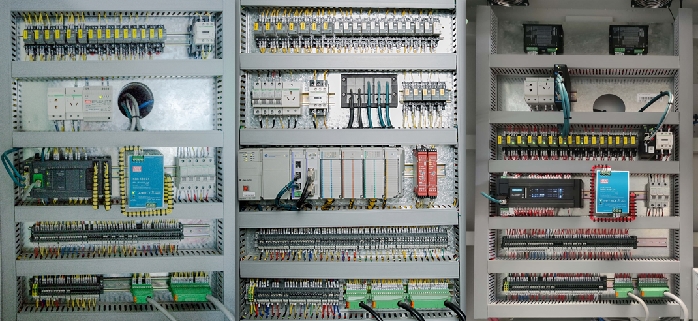

- The equipment is equipped with functions such as digital glue volume setting, one-click operation, and mechanical collaborative braking, making operation more intuitive and adjustment more flexible.

- The three-roll back pressure laminating mechanism and digital tension control system help achieve uniform adhesive application and more stable laminating quality.

Applications

The TRI-1300A Triplex Solventless Laminating Machine is designed for manufacturers producing high-barrier, multi-layer flexible packaging that requires three-layer lamination in a single pass.

1. Food Packaging

Snack pouches, coffee packaging, frozen and dry food bags with structures such as PET/AL/PE and BOPP/CPP/PE, where barrier performance and bonding strength are critical.

2. Pharmaceutical & Medical Packaging

Aluminum foil laminates and medical films requiring solvent-free processing and stable lamination quality.

3. Personal Care & Daily Chemical Packaging

Flexible packaging for cosmetics, detergents, and liquid products, benefiting from improved package strength and appearance.

4. Agricultural Packaging

Fertilizer and seed packaging requiring moisture resistance and mechanical durability.

Specification of Triplex Solventless Laminating Machine

| Maximum laminate speed | 450 m/m |

| Maximum laminate width | 1350 mm |

| Maximum unwinding diameter | 800 mm |

| Maximum rewinding diameter | 800 mm |

| Material loading mechanism | shaftless loading |

| Reel diameter | 3+6 inches |

Related Solventless Laminators

Have Other Questions?

Please fill in the following form, we will respond your request in 24 hours.