Introduction

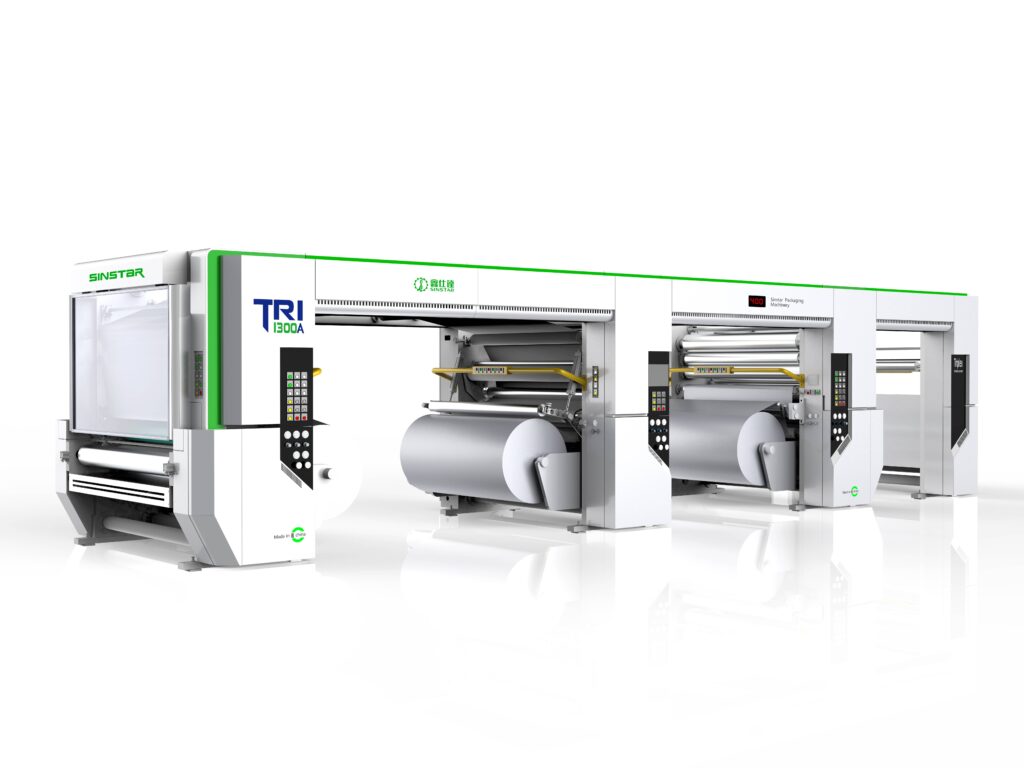

The Mini 500 laboratory solvent-free laminating machine is a compact and high-precision equipment, specially designed for laboratories, R&D centers and small packaging material manufacturers. It can conduct precise tests and small-scale production under conditions close to industrial standards.

It is mainly used in laboratory, R&D centers, university laboratories, glue factories’ laboratories, printing factories’ laboratories, and as supporting equipment for digital printing factories.

Main Advantages

- Cantilevered loading for laboratory easier to use

- Direct input of coating weight for a more convenient experiment

- Minimal material usage makes testing easier

- One-touch position adjustment of limited rollers, easier to clean

- Manual glue addition for added convenience in the laboratory

- Lowest testing cost

Applications

The Mini 500 Solventless Laminating Lab Equipment is designed for laboratory testing, R&D, and small-scale validation of solventless lamination processes. Typical applications include:

- Solventless Adhesive R&D and Formula Validation

Ideal for testing new solventless adhesive formulations, evaluating mix ratios, coating uniformity, initial bond strength, and curing performance under real lamination conditions. - Sample Lamination for Multi-Layer Packaging Structures

Suitable for common flexible packaging structures such as PET/PE, PET/CPP, OPP/PE, PET/AL/PE, and other multi-layer combinations. - Material Compatibility Testing

Enables evaluation of different film types, thicknesses, and surface treatments prior to full-scale production, reducing trial-and-error on production lines. - New Product Sampling and Customer Approval

Allows fast and repeatable production of high-quality laminated samples for customer evaluation, internal testing, and technical demonstrations. - Process Simulation and Parameter Optimization

Simulates key operating parameters of industrial solventless laminators—such as coating weight, nip pressure, and line speed—providing reliable data for scale-up. - Academic Research and Technical Training

Well-suited for universities, research institutes, and training centers focused on packaging materials and solventless lamination technology.

Specification of Mini 500 Lab Solventless Laminator

| Maximum laminate speed | 400 m/m |

| Maximum laminate width | 500 mm |

| Maximum unwinding diameter | 400 mm |

| Maximum rewinding diameter | 400 mm |

| Material loading mechanism | shaftless loading |

| Reel diameter | 3 inches |

Related Solventless Laminators

FAQ

Have Other Questions?

Please fill in the following form, we will respond your request in 24 hours.