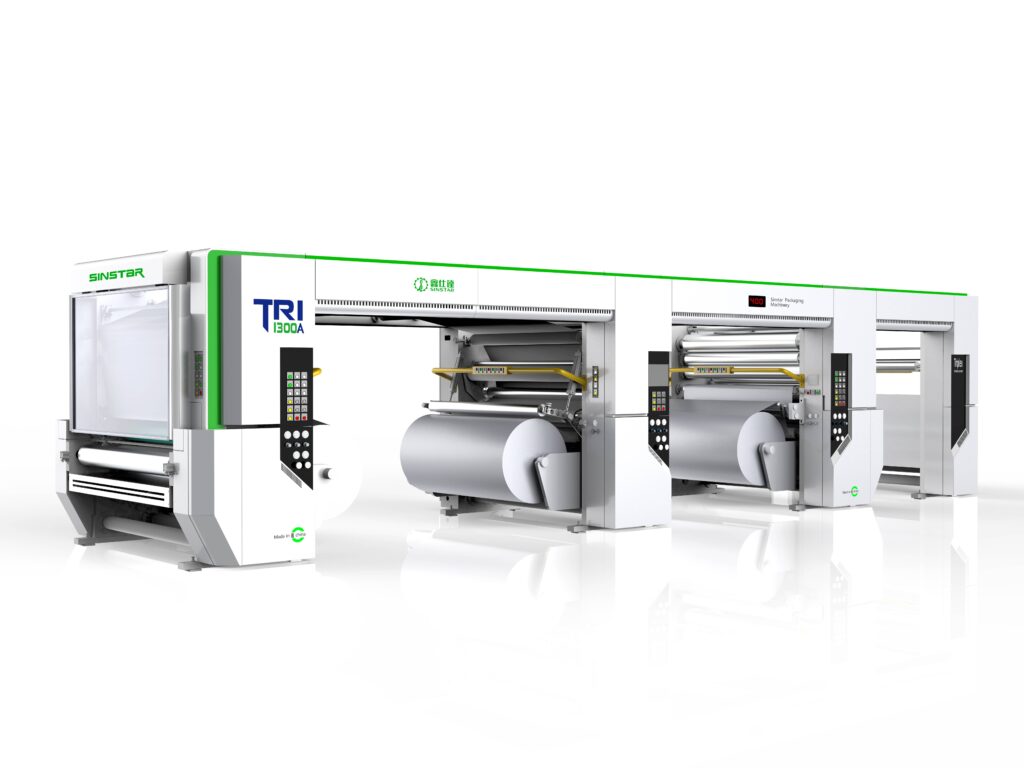

WRJF i9-1300A Solventless Laminating Machine

WRJ Fi9 solventless laminating machine is suitable for laminating different types of plastic films, metalized films, aluminum foils, and paper. It is one of the most popular models of multifunctional machines on the market.

Introduction

The WRJF i9-1300A is a high-performance solventless laminating machine designed for high-quality flexible packaging applications. In terms of lamination width and operating speed, it aligns with internationally recognized mid- to high-end solventless laminators. Equipped as standard with environmentally friendly lamination technology and advanced automation systems, the WRJF i9-1300A offers strong competitiveness in both export markets and domestic high-end packaging applications.

Compared with traditional solvent-based and dry lamination machines, the WRJF i9-1300A utilizes solventless lamination technology to deliver clear long-term advantages in production cost, operating efficiency, finished product quality, and operational safety. Its eco-friendly process and stable performance make it particularly suitable for packaging applications with stringent requirements, such as food, pharmaceutical, and high-end personal care packaging.

Main Advantages

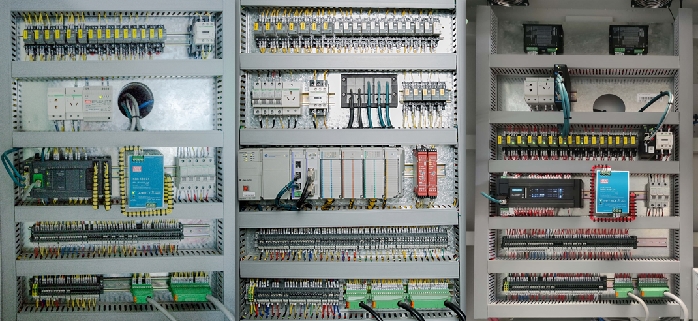

- Full PLC control system with touchscreen HMI, allowing operators to set lamination parameters precisely and store multiple production recipes for quick job changeovers.

- No drying system required, eliminating high-temperature drying processes and significantly reducing energy consumption.

- No solvent residue in the finished laminated films, making them highly suitable for food, pharmaceutical, and infant packaging applications with strict hygiene and safety requirements.

- Five-roller coating system with high mechanical precision, ensuring consistent coating performance and uniform adhesive layers across the entire web width.

- Equipped with precise adhesive weight measurement and closed-loop tension control, delivering stable lamination quality and minimizing material waste.

- Supports wide web widths and multiple material combinations, including BOPP, PET, PE, CPP, PA, aluminum foil, and other flexible packaging substrates.

Applications

1. Snack and Nut Packaging Bags

High-speed, wide-web lamination ensures solvent-free production, odor control, and strong interlayer bonding, ideal for continuous small-package manufacturing.

2. Frozen Food and Cold-Chain Packaging Films

Suitable for low-temperature resistance, high-barrier performance, and multi-layer structures, maintaining quality and safety during cold-chain transport.

3. Pharmaceutical Aluminum-Plastic Sachets

Meets hygienic standards with no solvent residue, suitable for tablets, granules, or powder packaging.

4. Infant Food and Milk Powder Packaging Bags

Ensures food-grade safety, sealing integrity, and batch consistency, meeting stringent requirements for mother and infant products.

5. Cosmetic Tubes and Face Mask Packaging Films

High-precision lamination guarantees smooth surfaces, attractive appearance, and stable adhesion.

Specification of WRJ i9-1300A Solventless Laminating Machine

| Maximum laminate speed | 450 m/m |

| Maximum laminate width | 1050/1350/1650 mm |

| Maximum unwinding diameter | 800 mm |

| Maximum rewinding diameter | 800 mm |

| Material loading mechanism | shaftless loading |

| Core | 3+6 inch |

Related Laminators

FAQ

Have Other Questions?

Please fill in the following form, we will respond your request in 24 hours.