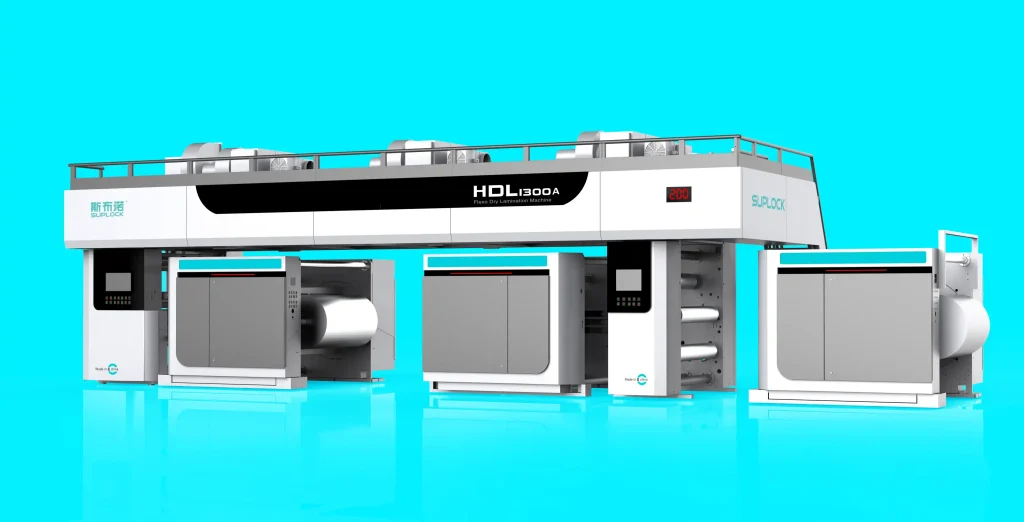

AU-1600A Breathable Film Solventless Laminating Machine

The breathable film lamination technology has become an important process in the hygiene products, medical protection and environmental protection packaging industries. Many breathable lamination film factories will combine breathable PE film with non-woven fabric. Produce functional composite materials that are both waterproof and breathable, with both comfort and barrier performance.

Applicable Products: Desiccant packaging, oxygen absorber packaging, bathroom materials, heat packs, plaster base materials, protective clothing, automotive headliners, etc.

Features of Breathable Film Solventless Laminating Machine

Compared with other solvent-free products on the market, our breathable film lamination system adopts an advanced point-coating solvent-free coating method and is combined with a special solvent-free wet-curing hot melt adhesive. While achieving high bonding strength, the key performance is to ensure that the material remains breathable but waterproof. The entire process truly achieves zero emissions, environmental protection and energy conservation. It does not require oven drying and is highly suitable for temperature-sensitive breathable PE film, baby diaper breathable film and other light film materials.

If you are in the hygiene products, medical protection, eco-packaging, or clothing, outdoor products and other industries, our breathable film laminator can help you stably manufacture high-quality breathable composite materials, easily meeting the high standards of the market for breathable but waterproof!

Specification of Breathable Film Solventless Laminating Machine

| Maximum laminate speed | 200 m/m |

| Maximum laminate width | 1350 mm |

| Maximum unwinding diameter | 1200 mm |

| Maximum rewinding diameter | 1200 mm |

| Material loading mechanism | shaftless loading |

| Core | 3+6 inch |

More Details

Related Solventless Laminators

Get Free Quote

Please fill in the following form, we will respond your request in 24 hours.