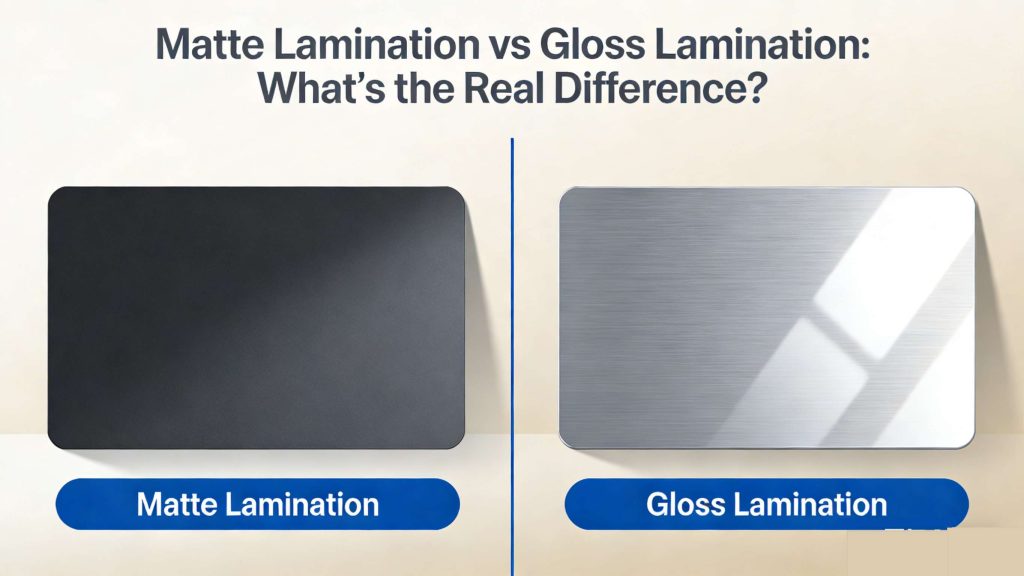

Matte Lamination vs Gloss Lamination: What’s the Real Difference?

In the printing and packaging industry, laminating is a common and important process. It not only protects paper and packaging materials from scratches, stains and moisture, but also enhances the overall visual effect, making the products look more refined and professional. However, when faced with matte lamination and gloss lamination, many people have questions: What are the differences between them? Which one is more suitable for my project?

This article will analyze the differences between the two from multiple perspectives such as concept, visual effect, touch, durability and application scenarios, and provide you with a detailed explanation to make the choice easier.

What Is Matte Lamination?

Matte Lamination is a process that creates a smooth, low-reflective protective layer on the surface of paper or packaging. By using a professional lamination machine, the film layer can be made uniform and have a delicate touch, while maintaining color accuracy. For small batches or high-end printed products, such machines are particularly suitable. The most notable feature is that it offers a soft and low-key visual effect, giving a sense of stability and high-endness. Many high-end business cards, gift boxes, brochures, and art-related printed materials prefer to use silk-screen lamination because it makes the products appear more textured and has a delicate touch, providing a comfortable hand feel experience.

Regarding water resistance, many people will be concerned about “is matte lamination waterproof?“. Generally speaking, matte laminating has a certain degree of waterproofing ability, which can prevent minor moisture or short-term splashes of water from causing damage to the paper. However, it is not completely waterproof. If the materials need to be in contact with water for a long time or be used in a humid environment, it is best to add a special waterproof film or take additional measures during the design and packaging process.

Apart from its protective function, the low-reflective characteristic of matte lamination also helps maintain readability in high-light environments, preventing text and images from being disturbed by glare. This is why many art works, photography books, and high-end packaging prefer to use matte lamination. Additionally, although matte lamination performs well in terms of water resistance, compared to smooth gloss lamination, it is more susceptible to scratches caused by fingernails or metal objects.

What is a Gloss Lamination?

The gloss lamination forms a bright protective layer on the surface of the printed material, making the colors more vivid and the images and text more lifelike. Its glossy effect not only enhances the visual impact but also makes the printed materials more eye-catching when displayed or sold.

Gloss lamination is commonly found on menus, posters, product labels, brochures, and packaging products that need to attract consumers’ attention. Compared to matte finish, gloss lamination usually has better water resistance and durability, thus performing more stably in long-term use or environments where frequent contact is required. However, gloss lamination is prone to leaving fingerprints and scratches, which means more attention needs to be paid during use and storage, especially in scenarios with high-frequency operations.

It is worth noting that the glossy finish of the lamination can enhance the color saturation, making the red, blue, green and other colors in the printed materials appear more vivid and with higher contrast. For product packaging or advertising materials, this effect is often more suitable for attracting attention and highlighting the brand characteristics.

Matte Lamination vs Gloss Lamination: What’s the Difference?

Visual Appearance

Matte lamination provides a soft, understated and non-reflective finish. As a whole, it looks stable and has a high quality, making it highly suitable for designs with a high-end style. The gloss lamination is eye-catching and bright, immediately drawing attention. The images and text appear more prominent, making it an ideal choice for brochures, posters or product labels.

Texture

The matte film has a delicate and smooth touch, feeling comfortable and natural when touched. It is suitable for people to hold and immediately perceive the quality. The glossy film, although shiny and smooth, is prone to leaving fingerprints on hands. Therefore, when using it, one needs to be a little cautious, especially on products or exhibits that are frequently touched.

Color Reproduction

The matte lamination gives the color a soft and low-key effect, with low contrast, making it more suitable for showcasing details or for a subtle design style. The gloss lamination, on the other hand, makes the color more saturated, with higher contrast, and makes images and text more prominent. If your design requires a strong visual impact or bright colors, the gloss lamination is often a better choice.

Durability

In terms of durability, glossy film lamination usually performs better, offering higher waterproof, scratch-resistant and wear-resistant properties, making it suitable for frequently used or long-term contact printed materials. matte lamination, although having limited protective capabilities, has a low reflection characteristic that makes printed materials easier to read in bright environments, and it also adds more texture to some high-end packaging. Depending on the usage scenario, choosing the appropriate film lamination type can balance both appearance and durability.

Cost

The manufacturing process of matte lamination is slightly more complicated, so the cost is usually higher than that of gloss lamination. The gloss lamination process is mature and the production is relatively simple, making it suitable for mass production and better suited for cost control. For promotional materials or packaging that require extensive printing, gloss lamination is often an economical choice.

How to Choose the Right Lamination?

There is no absolute right or wrong when choosing film lamination. The decision mainly depends on the purpose of your product, the design style, and the usage environment. The following points can serve as references:

- For high-end business cards, gift packaging, artistic books, etc., choosing matte lamination makes them appear more stable and upscale; for brochures, posters or product labels, if you want to attract attention and highlight colors, glossy film lamination is more suitable.

- The gloss lamination performs better in terms of water resistance and wear resistance. If the product needs to be frequently exposed to water or requires frequent hand operation, a gloss lamination is more practical. The matte lamination is suitable for relatively refined, high-end, and low-frequency products. To achieve a uniform matte lamination effect and stable luster, it is very important to choose a high-precision lamination machine. The temperature, pressure, and speed control of the machine directly affect the lamination effect.

- Matte finish is Matte is soft and subtle, glossy finish is bright and vivid. They can be flexibly used in combination according to the overall brand style.

- During mass production, the smooth-coated film process is mature and has lower costs; however, for small-batch production of high-end products that emphasize texture, matte-coated film is more suitable.

Some designers pair matte lamination with spot gloss to create visual depth. By matte-finishing the background and glossing specific details, the design accentuates focal points without losing its sophisticated, low-key aesthetic.

Matte lamination and gloss lamination each have their own characteristics. matte lamination is low-key and soft, suitable for serious and high-end designs. It has a comfortable touch and a good reading experience; gloss lamination is bright and vivid, more suitable for attracting attention and highlighting colors, and it also offers better protection. By considering your product’s usage, design style, and usage environment, you can choose the most suitable lamination type, making each product both aesthetically pleasing and functional.

Choosing the type of film lamination is not only a design decision but also involves the selection of production equipment. To achieve the desired matte or glossy effect, it is recommended to use the professional film lamination machine from Sinstar, which supports various film materials and printing specifications, helping you easily achieve high-quality film lamination results.