From Food to Pharma: How Laminated Films Improve Tamperproof Container Safety

In the food and pharmaceutical industries, people are paying increasing attention to the safety of packaging. With the globalization of supply chains and the acceleration of product circulation, packaging not only needs to protect product quality but also ensure that consumers can determine whether the product has been opened or tampered with. Against this backdrop, tamper-proof packaging has gradually evolved from an added value to a fundamental responsibility that brands must fulfill.

The development of modern flexible packaging has enabled laminated films to play an increasingly important role in tamper-proof systems. Whether it is the individual small packaging of food or the strip packaging and tablet soft bags of pharmaceutical products, laminated film has become an indispensable material for ensuring packaging integrity and enhancing usage safety.

This article will start from the food to pharmaceutical industries, comprehensively analyze how laminated films can help enterprises build a safer tamper-proof packaging system, and at the same time introduce the true value of solvent-free lamination technology.

What Is Tamper-Proof Packaging? Why Is It Becoming Increasingly Important?

The main purpose of Tamper–proof or Tamper-evident packaging is to ensure that the packaging will not be easily opened or resealed during circulation and use. Even if the packaging is damaged, clear and obvious marks must be left to help consumers quickly identify possible risks.

Typical application fields include:

- Infant complementary foods and milk powder

- Medicines and health supplements

- Medical devices and medical consumables

- Beverages, snacks and condiments

- Cosmetics and topical products

With the development of e-commerce retail, products need to go through more intermediate links before reaching consumers, and the demand for tamper-proof packaging has been further magnified. The market’s requirements for this type of packaging have gradually upgraded from visible to verifiable, with a greater emphasis on structural reliability and material performance.

How Does Laminated Film Enhance The Tamper-Proof Ability Of Packaging?

Laminated films are made by combining two or more layers of different materials through a lamination process. Therefore, their structure naturally has higher strength, more stable adhesion and better barrier effect than single-layer films.

1. The multi-layer structure enhances the overall strength

Each layer of material undertakes a different function:

- PET offers rigidity and tensile resistance

- AL and MPET offer oxygen barrier and light barrier properties

- PE offers heat sealing and flexibility

Multi-layer superposition makes the packaging less likely to be easily torn or punctured by external forces, which is also the most fundamental tamper-proof capability in food and pharmaceutical packaging.

2. It adheres firmly, making it difficult to peel off by hand

The higher the bonding strength of the laminated film is, the more difficult it is for the layers to peel off from one another. Weak bonding is prone to being pried open from the edge and may even allow lawbreakers to tamper with it through “opening and resealing”. High-quality laminated films can effectively prevent such situations.

3. Enhanced sealing performance for overall protection

High heat-sealing strength means that cracks or loosening are less likely to occur at the sealing area. For some products containing oil, water or active ingredients, the sealing strength is directly related to stability and safety.

4. High barrier performance extends the product’s stability time

The multi-layer barrier structure of the laminated film can effectively prevent oxygen, water vapor and light from entering the interior of the packaging, reducing the probability of food oxidation and drug failure. This is equally important in a tamper-proof system, as damaging the packaging usually means that these external factors will quickly affect the contents.

How Can Solventless Lamination Processes Further Enhance Tamper-Proof Performance?

Compared with traditional solvent-based processes, solvent-free lamination is becoming an important process choice for food and pharmaceutical packaging due to its environmental friendliness, safety and high consistency.

1. Uniform bonding, reducing weak points

Solvent-free lamination employs a precise metering system, which can ensure consistent adhesive application, thereby reducing the risk of delamination caused by insufficient local bonding.

2. High bonding performance enhances anti-damage capacity

Solvent-free lamination adhesives usually have high initial adhesion and final strength, making it difficult for the laminated film to crack at the edges or be artificially separated.

3. No solvent residue, suitable for sensitive products

Pharmaceuticals and baby food have very high safety requirements, and residual solvents may become potential risks. Solvent-free lamination eliminates this problem, making the packaging more suitable for high-standard products.

4. High-speed production ensures batch consistency

High-speed solvent-free laminating machines can ensure that each batch of laminating films has similar structure and performance. For a large number of small-packaged products on the market, consistency is particularly crucial.

Application in Food Packaging: How can laminated films Achieve Greater Value?

Food packaging appears very frequently in consumers’ lives. Therefore, the tamper-proof function not only needs to be reliable but also must take into account the user experience.

1. Infant and toddler food: Stricter safety requirements

Baby complementary foods generally adopt high-barrier lamination structures to ensure that the products are not contaminated during transportation and storage. The obvious marks left when opening the package can also help parents more confidently determine its safety.

2. Snack foods: Traces can be seen immediately upon opening

For snack packaging, the experience of opening the package must be clear and irreversible. The tear-resistant property of the laminated film ensures that once the tear is opened, it cannot be restored.

3. Sauces and ready-to-eat meals: Pay attention to the sealing strength and oil resistance

Oily products are more likely to affect the sealing quality. The bonding structure and heat-sealing layer of the laminated film can effectively reduce the risk of leakage.

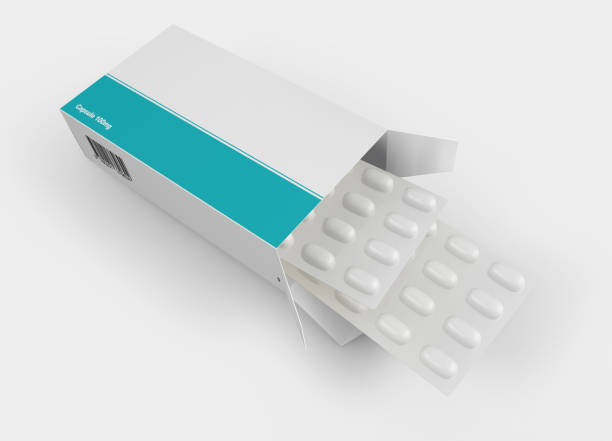

Application in Pharmaceutical Packaging: Higher Standards, Higher Performance

Pharmaceutical products not only need to be tamper-proof but also comply with strict regulatory requirements. laminated films are precisely the important material to address this issue.

1. Sealing integrity is the core

Medicines are often highly sensitive to oxygen, water vapor and photosensitivity. High-barrier laminated films can provide sufficient protection.

2. The irreversibility of opening enhances security

Medical soft bags, strip packages and other structures will immediately lose their original form after opening, which is crucial for preventing secondary sealing.

3. Compatibility with multiple dosage forms

Different types of drugs can all find matching lamination membrane structures, for example:

- The powder requires higher barrier properties

- Tablets need to have good stiffness

- Gel types require higher sealing performance

4. The VOC-free process is more in line with regulations

The laminated film produced by solvent-free laminating machines can meet the safety material standards of the pharmaceutical industry and is a trend-driven process.

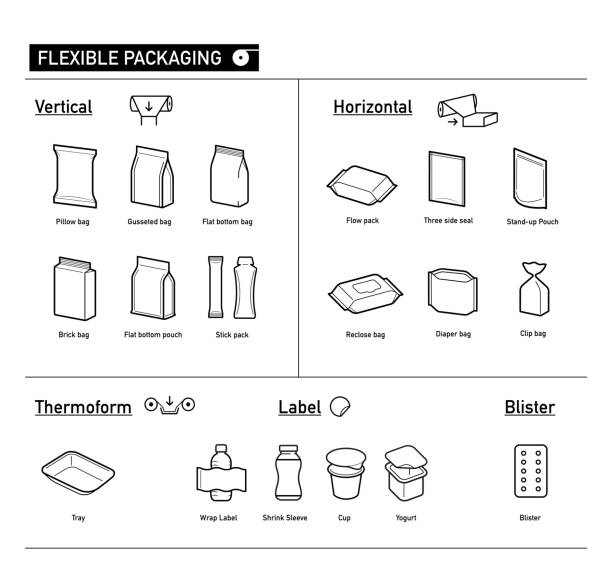

Common Tamper-Proof Lamination Structures And Bag Types

Enterprises usually choose different structures based on their own product requirements, for example:

- PET/AL/PE: High barrier, high strength

- PET/MPET/PE: High cost performance and widely used

- PET/PE: Suitable for general food

- Multi-layer custom barrier structure: Suitable for pharmaceuticals and sensitive contents

Common bag types include four-sided sealed bags, stand-up bags, strip bags, one-piece bags and medical-grade soft bags, etc. These bag types also incorporate various tamper-proof elements during the design process, such as easy-tear openings, laser-tear lines, and anti-opening adhesive layers.

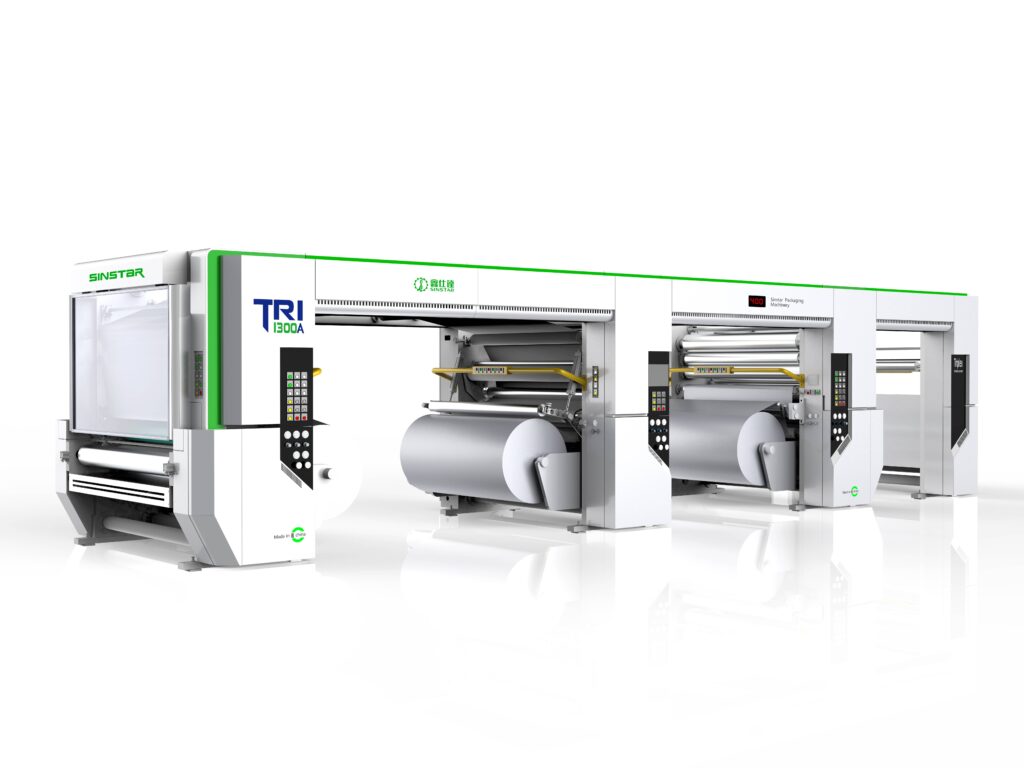

How To Build a More Stable Tamper-Proof Packaging System With Advanced Solventless Laminating Machine?

To ensure that the tamper-proof performance reaches the expected level, both lamination materials and lamination equipment are of vital importance.

Advanced solvent-free laminating machines have the following advantages:

- Precise coating amount control to prevent poor bonding

- The fully automatic tension system ensures that the lamination layer is flat and consistent

- Stable high-speed operation increases production capacity and reduces batch variations

- Supports multiple substrates and provides flexible solutions for food and medicine

These properties collectively enhance the structural stability and tamper-proof capability of the laminated film, enabling it to maintain reliable performance in various packaging applications.

In the industry, an increasing number of flexible packaging enterprises choose to use Sinstar solvent-free lamination solutions to enhance the reliability of their products in tamper-proof packaging. Sinstar specializes in lamination equipment for food and pharmaceutical packaging. The equipment performs stably in terms of bonding consistency, environmental performance and high-speed operation, and can help enterprises build a higher standard packaging safety system.

Conclusion

From food to pharmacy, the importance of tamper-proof packaging will only continue to increase. laminated films, with their multi-layer structure, high barrier performance and excellent bonding strength, provide a reliable foundation for tamper-proof packaging. The maturity of solvent-free lamination technology has further enhanced the safety, stability and environmental friendliness of laminated films.With the development of the industry, tamper-proof packaging will continue to evolve towards high barrier, environmental protection and intelligence in the future. No matter how trends change, high-quality laminated films and advanced lamination processes will remain the key to the entire packaging safety system.