What Is The Difference Between Wet Lamination And Dry Lamination?

In the printing, packaging, labeling and composite materials industries, lamination processes almost run through all aspects of product appearance protection and performance improvement. Whether it is composite film for food packaging, book covers, promotional materials or functional films, the quality of lamination will directly affect the service life, visual effect and user experience of the product.

Among various processes, wet lamination and dry lamination are the two most common methods. However, many people encounter doubts when choosing a process: Which one is more suitable for the current material and production requirements? Where exactly lies the difference between the two? How will costs and production capacity be affected?

This article will help you understand the underlying rules of these two processes more systematically from aspects such as what dry lamination and wet lamination are and a comparison of their advantages and disadvantages, and make a more accurate choice.

What Is Wet Lamination?

Wet lamination is a traditional lamination method that uses liquid adhesives for bonding. Modern wet lamination technology has become highly mature. Its stability and low cost are the key reasons why many printing enterprises still adopt this process for a long time.

The workflow of wet lamination

- Apply liquid adhesive (such as water-based adhesive or solvent-based adhesive) on the surface of the substrate.

- The thickness of the adhesive layer is controlled through a uniform roller system.

- Bond with the film material.

- Enter the oven and let the moisture or solvents evaporate through hot air, infrared rays and other means.

- After the adhesive layer is cured, it is leveled by the pressure roller to make the bond more firm.

- Cool and coil.

The key to the entire process lies in the drying and curing quality of the adhesive layer, which directly determines the bonding strength and the final flatness.

Common materials for wet lamination

- All kinds of paper (coated paper, grey card, white card, etc.)

- Rough, porous or highly absorbent materials

- Some structural composite materials that require relatively strong bonding strength

Because paper is absorbent, its surface can allow liquid glue to form a good bond, which is usually more secure than dry lamination.

What Is Dry Lamination?

Dry lamination uses a film pre-coated with a solid adhesive layer. The adhesive layer is reactivated by heat or pressure and then bonded to the substrate. The core advantage of this process is that it does not require a long drying time, making the production process simpler and faster.

The workflow of dry lamination

- Use a pre-coated film with adhesive (hot melt adhesive film or pressure-sensitive adhesive film).

- When the membrane material enters the heating zone, the adhesive layer is activated.

- The bonding is completed using a pressure roller.

- Cool to stabilize the bonding strength.

- Roll up or slit the finished product.

As no solvent evaporation is required, the entire production line is shorter, occupies less space and is easier to control in operation.

Materials suitable for dry lamination

- Plastic films such as PET, BOPP, and PVC

- Metal foil (aluminum foil, etc.

- Glossy paper, coated paper

- All kinds of transparent protective films and functional films

- Packaging materials for food, medicine, etc

- Label base materials, heat-sealing films, etc

Especially for film materials, dry lamination can provide a more stable and cleaner composite effect.

The Differences Between The Two Processes: Why Do They Affect The Final Effect?

Although the goals are the same, the principles of the two lamination methods are completely different. This difference will naturally extend to production line speed, bonding strength, environmental protection requirements and investment costs.

| Wet Lamination | Dry Lamination | |

| Bonding Method | Liquid adhesive penetrates and cures | Pre-applied adhesive activated for bonding |

| Curing Method | Requires drying of water/solvent | Cools down to set |

| Production Line Structure | Includes oven, larger equipment footprint | Compact equipment, shorter process |

| Speed | Slower, limited by drying | Fast, instant bonding |

| Environmental Impact | Requires VOC handling (if solvent-based) | Essentially VOC-free, more eco-friendly |

| Adhesion Strength | Stronger for paper | Better for films, high stability |

For instance, in the food packaging industry that demands high-speed production, dry lamination is almost the mainstream. In the production line of book covers, wet lamination still dominates.

Which Materials Are Suitable For Wet Lamination? Which Ones Are Suitable For Dry Lamination?

To avoid rework, the process must be selected based on the surface characteristics of the material.

Materials suitable for wet lamination

- All kinds of paper: Water absorption makes the adhesive layer more easily penetrate

- Materials with porous structures or rough surfaces

- Low-cost, high-volume printed materials

- Thick cardboard type cover or packaging box structure

Wet lamination can establish a deeper bond, and thus is more suitable for paper products with high strength requirements.

Materials suitable for dry lamination

- Plastic films (PET, PP, PE, etc.

- Aluminum foil and other metal materials

- Heat-sealing film, composite film structure

- Functional film materials such as transparent films and protective films

- Food-grade packaging materials

- All kinds of label substrates

Dry lamination can better ensure the flatness, transparency and cleanliness of the film.

The Advantages And Disadvantages Of Dry Lamination And Wet Lamination

To help with a quick judgment, more detailed comparison dimensions are listed here.

Advantages of dry lamination

- Fast speed: No need to wait for drying, and high-speed continuous production can be achieved.

- Stronger environmental friendliness: No solvent evaporation, making it easier for the workshop to meet standards.

- Wide material adaptability: especially for film-type materials.

- Cleaner process: Less likely to cause pollution problems.

- Suitable for high-demand products: such as packaging materials with high transparency and high temperature resistance.

Disadvantages of dry lamination

- The cost of pre-coated film materials is relatively high.

- The adhesion effect of rough materials is not as good as that of wet type.

- The requirements for temperature and pressure control are stricter.

Advantages of wet lamination

- It has high bonding strength and is suitable for water-absorbing materials.

- The equipment is mature and the process cost is relatively low.

- It can be used on thicker or rougher substrates.

Disadvantages of wet lamination

- The manufacturing process is relatively long and requires drying.

- If solvent-based adhesives are used, VOC emissions need to be treated.

- It is greatly affected by temperature and humidity.

- Higher requirements are placed on the workshop space.

How Much Does The Difference In Drying Time Affect Efficiency?

In wet lamination, the glue must be completely dry to ensure good adhesion, so the drying efficiency will affect the speed of the entire production line.

The drying process involves:

- Thickness of the adhesive layer

- Oven temperature

- Wind speed and exhaust system

- The temperature resistance of the material

Even on well-optimized production lines, the speed of wet lamination is usually still slower than that of dry lamination. Dry lamination can achieve a faster lamination speed because it does not require the evaporation of water or solvents, which is particularly evident for large orders or continuous production.

How To Choose The Right Laminating Equipment?

When planning a laminating production line, the selection of equipment often determines production efficiency and product quality. Although both wet and dry laminating equipment can achieve material bonding, there are obvious differences in structural configuration and application scope. Understanding these differences helps to make a more scientific selection based on one’s own business needs.

The characteristics of wet laminating equipment

Wet lamination takes the coating of adhesive as its core, so the equipment is centered around “coating – drying – lamination”.

The main features include:

- The coating system determines the stability of the adhesive amount

The control of adhesive amount directly affects the bonding strength and surface flatness, and the uniformity of the coating system is extremely crucial.

- The drying equipment is relatively large in size

To completely evaporate solvents or moisture, ovens are usually longer and occupy a significantly larger area than dry laminating equipment.

- Solvent-based processes need to be equipped with exhaust and environmental protection systems

Enterprises need to take into account VOC emissions and safety protection, and have higher requirements for factory conditions.

- It is more suitable for paper processing enterprises

It includes base materials such as cardstock, coated paper, and color box paper. Due to the good adsorption property of the paper, wet lamination can achieve stable and economical results.

The characteristics of dry laminating equipment

Dry lamination uses pre-coated adhesive film for heating and bonding, so the equipment structure is more compact.

Its common advantages include:

- It occupies less space and has a more compact layout

There is no need for large drying tunnels, and the requirements for factory space are lower.

- Configure the heating roller, pressure roller and cooling system

The flatness and stability of the composite are ensured through hot-pressing and rapid cooling.

- Tension control is even more crucial

Most of them are thin-film materials, which are sensitive to tension changes and require more precise transmission and control systems.

- Suitable for packaging, film and functional film manufacturing enterprises

In industries such as BOPP, PET, metallized films, and protective films, the product range is rich, and dry lamination is more flexible.

Equipment selection suggestions: What factors should be focused on?

Before evaluating specific equipment, the following perspectives can be considered for judgment:

- Whether high-speed production is required (if so, dry lamination is mostly chosen)

- VOC and environmental protection regulations requirements (If the restrictions are strict, dry type is more preferred)

- Workshop space and temperature and humidity conditions

- Raw material characteristics and customer industry types

- Investment budget and later maintenance costs

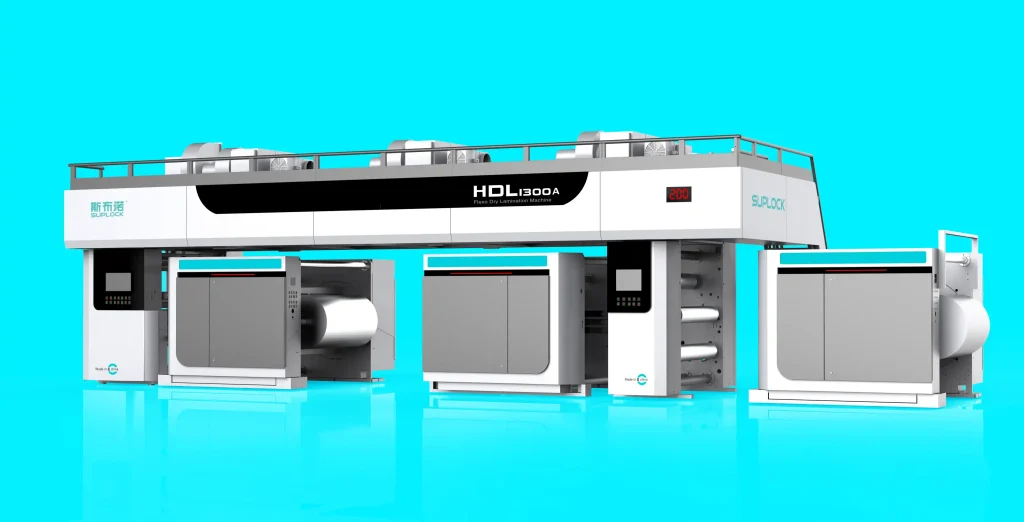

Overall, if an enterprise needs to handle multiple film materials or face a large number of packaging orders, dry laminating equipment has higher adaptability. Our HDL dual-station dry hard laminating machine can support dual-station operation simultaneously, improve production efficiency, and adapt to different types of functional films and packaging materials. Factories that mainly use paper packaging usually still tend to use wet lamination because of its low cost and stable operation.

Which Laminating Method Should Be Chosen For Heat-Sensitive Materials?

Thermal paper, thermal labels and some special films are prone to discoloration or failure when heated, so the lamination method must minimize heat exposure as much as possible.

More recommended: Low-temperature dry lamination

- Pressure-sensitive adhesive film or low-temperature hot melt adhesive film is adopted

- The lamination temperature is significantly lower than that of ordinary dry lamination

- It can effectively protect the structure of the heat-sensitive layer

- For most enterprises, this approach has a higher success rate and product stability.

Is wet lamination feasible?

It can be used, but the conditions are rather strict:

- The glue should be of low-temperature curing type

- The temperature of the oven must be reduced

- Reduce heat exposure by shortening the drying zone or drying in sections

Although the wet solution can also achieve production, it has very high requirements for parameter control. Therefore, the industry generally still adopts low-temperature dry lamination as the mainstream choice.

Final Words

The selection of lamination processes is not a single standard, but rather requires finding a balance among material properties, production efficiency and environmental protection requirements. Different materials and applications determine the focus of the process. Wet lamination is more suitable for paper materials, while dry lamination performs better in the fields of thin films and functional films. In actual production, speed, cost and the protection requirements of special materials will all affect the final choice.

Sinstar is dedicated to the production of solvent-free laminating machines. Any laminating machine you want can be found here.