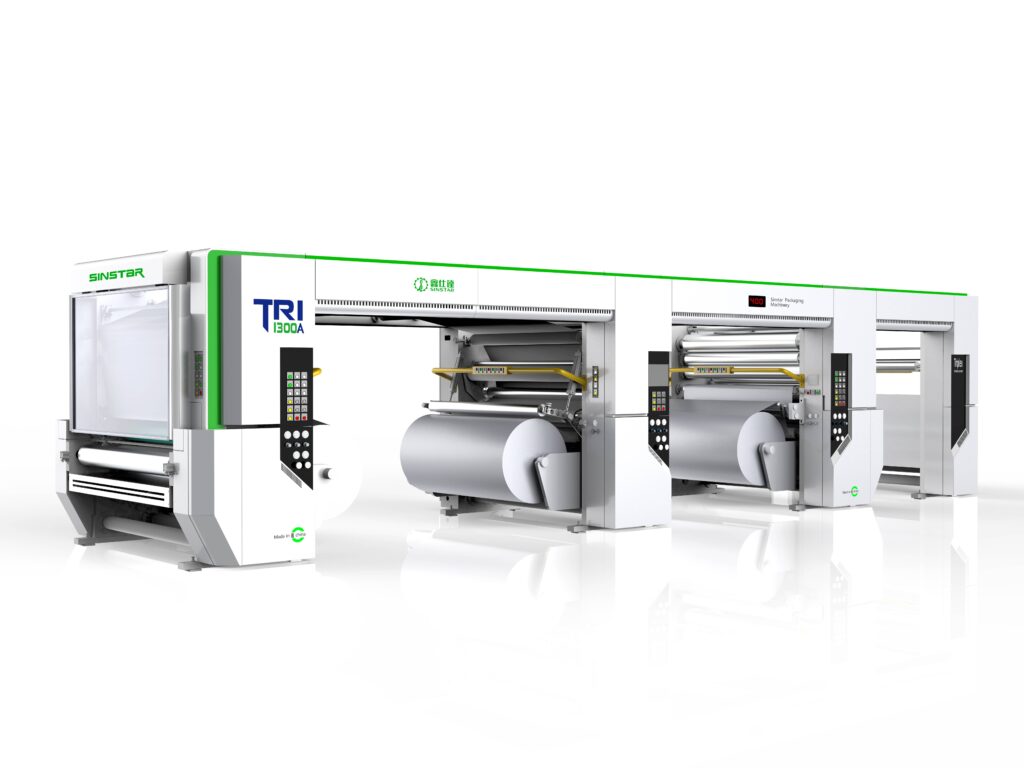

How to Choose the Right Solventless Laminating Machine for Your Packaging Business

The solventless laminating machine has become an important part of modern flexible packaging factories as more and more of the global packaging industry switches to eco-friendly, VOC-free options. More converters and brand owners are switching from solvent-based lamination to solventless technology because of rules, food safety standards, and the growing popularity of eco-friendly packaging.

However, purchasing the right solventless laminating machine requires far more than comparing catalog parameters. Buyers must evaluate production needs, material structures, adhesive compatibility, long-term operational costs, and the credibility of equipment suppliers. This guide explains everything a purchaser should know before selecting a new solventless laminator — especially for companies sourcing from solventless laminating machine manufacturers in China, where global demand is rapidly increasing.

Part 1. Start with Your Actual Production Requirements

Before comparing brands or negotiating solventless lamination machine price, the most important step is understanding what your production line truly requires.

Define your packaging materials and structures

Different film structures require different technical capabilities. Consider whether your product uses:

- BOPP, PET, PE, CPP, Nylon (PA)

- Aluminum foil or metalized films

- Paper-plastic composite structures

- Two-layer or three-layer (triplex) laminations

Should your production often have high-barrier films or multi-material packaging, a solventless laminator with high tension control, stable adhesive metering, and good substrate versatility will be absolutely necessary.

Determine actual production capacity

- Small factories and new product development lines can use mid-range models with speeds of around 100 to 180 m/min.

- For large scale converters, machines are often required to run at 300 to 450 m/min for streamlined operations.

Choosing the right one affects, in real time, the output efficiency, the workload on the operators, and the time for delivery.

Consider future expansion

A growing number of factories prefer machines that can be upgraded later — for example, from duplex lamination to triplex lamination. Planning ahead prevents costly equipment replacement in the future.

Part 2: Key Technical Parameters You Must Evaluate

The fundamental systems of a solventless laminating machine have a big effect on how well it works. When looking at machine specs, pay attention to the following:

Adhesive coating & mixing system

Polyurethane (PU) or other high-solid adhesives are used in solventless lamination. So, a system for mixing and applying adhesives with great accuracy is necessary.

Check for:

- Stable A/B component mixing ratio

- Accurate coating weight control

- Automatic viscosity and temperature monitoring

- Low adhesive waste and easy cleaning

These directly affect lamination quality and long-term production cost.

Tension control and web-handling system

Advanced tension control makes sure that laminations are smooth and free of wrinkles and that they adhere correctly. A good system should have:

- Fully automatic tension adjustment

- Multi-zone web control

- Stable handling of ultra-thin or high-shrinkage films

- Minimal material waste during acceleration or deceleration

For buyers handling aluminum foil or sensitive films, this is especially important.

Lamination speed and energy efficiency

The productivity of a company that invests in a fast solventless laminator is bound to see a huge productivity boost. On top of that, their running costs are also bound to lower because of energy-saving motors and efficient heating systems.

There needs to be a balance between high speeds and stable lamination.

Pressure, temperature, and curing performance

- See if the pressure rollers maintain an even lamination pressure.

- Confirm the machine meets the curing requirements of your adhesive suppliers.

- A mismatch can lead to poor peel strength or even delamination.

Part 3. Choosing the Right Manufacturer: Reliability Comes First

A lot of buyers these days look to China for manufacturers of solventless laminating machines. There has been a great improvement in technological capability in the past 10 years, but buyers still need to differentiate between one’s ‘low-end assembly workshops’ and ‘established manufacturers who have strong engineering capabilities’.

Evaluate R&D capability and manufacturing quality

Reliable producers should offer:

- In-house machining capability

- Independent R&D on coating heads and tension units

- UL/CE/ISO certifications

- Real customer cases in food or pharmaceutical packaging

Avoid suppliers that only assemble components without QC systems.

After-sales service and global support

A solventless laminator is a long-term investment. Ensure the supplier provides:

- On-site installation and operator training

- Remote diagnostics

- Fast spare parts supply

- 24/7 service availability

International customers need reliable technical support to reduce downtime.

Part 4. Understanding Solventless Lamination Machine Price

Solventless laminating machine price varies widely depending on configuration, automation level, and lamination width.

Typical price ranges:

- Entry-level/small-scale models: USD 15,000–40,000

- Mid-range models for commercial production: USD 45,000–90,000

- High-speed triplex solventless laminators: USD 100,000–250,000+

However, buyers must also consider hidden or long-term costs:

Additional investment factors

- Installation and commissioning

- Operator training

- Adhesive testing and material compatibility

- Electrical and facility upgrades

Long-term cost of ownership

A cheaper machine may result in:

- Higher adhesive consumption

- Frequent maintenance

- Lower lamination quality

- More downtime

In many cases, a higher-quality machine lowers total cost over 5–10 years.

Part 5. Adhesive Compatibility — The Most Overlooked Factor

Many buyers focus on machine price and speed but forget to check adhesive compatibility.

Solventless adhesives differ by:

- Composition

- Viscosity

- Coating thickness requirements

- Curing time

Before purchasing, always request:

- Material tests

- Peel-strength data

- Coating-weight evaluation

A responsible manufacturer should offer sample testing services using your actual substrates and adhesives.

Part 6. Environmental Compliance and Food-Safety Standards

Since solventless lamination eliminates VOC emissions and solvent residues, it is increasingly favored in:

- Food packaging

- Baby-care products

- Medical packaging

- High-barrier flexible packaging

- Ensure the machine meets:

- Global VOC control regulations

- FDA/EU food-contact packaging requirements

- Local environmental inspection standards

Choosing solventless lamination also helps companies meet ESG and sustainability goals.

Part 7. Always Perform Factory Trials Before Buying

Before finalizing your order, visit the supplier’s plant or request live video testing.

Key evaluation points include:

- Smoothness of lamination

- Adhesive distribution and coating uniformity

- Noise level and operator ergonomics

- Startup waste and changeover speed

- Stability at high speeds

Real-world demos are the most accurate way to judge equipment quality.

Part 8. Final Checklist for Making the Right Decision

Before purchasing a solventless laminating machine, confirm the following:

- Required lamination speed

- Film and substrate compatibility

- Adhesive metering accuracy

- Automatic tension control capability

- After-sales and spare parts availability

- Energy efficiency

- Ability to upgrade to triplex lamination

- Tested sample quality and curing performance

A good solventless laminating machine will help you make things more stable, have less of an effect on the environment, and make more money in the long run.

FAQ: Frequently Asked Questions About Solventless Laminating Machines

1. What is a solventless laminating machine?

A laminating machine that doesn’t use solvents employs 100% solid adhesives, which cuts down on VOC emissions and energy utilization. It is used a lot in food, medicine, and flexible packaging.

2. What are the advantages of solventless lamination?

- Zero VOC emissions

- Lower energy consumption

- Faster production

- Reduced adhesive waste

- Better food-safety compliance

3. Do I need special adhesives for solventless machines?

Yes. Only polyurethane (PU) without solvents or special high-solid adhesives work with this. Always ask the person who sold you the machine to test the glue.

4. How long does curing take?

Most solventless adhesives dry in 12 to 48 hours, but this varies based on the formula, temperature, and film structure.

5. Can the machine be upgraded later?

Many modern solventless laminators support upgrades such as:

- Adding triplex lamination

- Enhanced tension zones

- Automated adhesive mixing systems

6. Should I visit the manufacturer before buying?

Highly recommended. A factory visit or live video trial allows you to evaluate:

- Actual lamination quality

- Machine stability at high speed

- Adhesive distribution

- Operator ergonomics

- Changeover speed and material waste

Demonstrations in the real world are the greatest way to anticipate long-term performance.