7 Things to Consider to Ensure Your Product Packaging Success

In the current retail environment that is extremely competitive, packaging has changed its meaning from just a container to a whole new concept, and one has to consider a lot of factors when creating a package for a product. It is the brand’s “first handshake” with the consumer and a highly sophisticated piece of engineering at the same time. Many companies risk the aesthetics of the packaging to get huge profits, but they face catastrophic failures like delamination, product spoilage or transit damage after the product has reached a store. These problems do not only result in monetary loss, but they also give rise to distrust among the customers.

What are the factors that make a packaging solution successful? Earlier moving into mass production, these 7 significant things have to be evaluated systematically.

1. Material

The aspect of packaging development that is the most basic but still often neglected is the chemical compatibility between content and material. Different product formulations, for instance, high-fat foods, alcohol-based cosmetics, or corrosive chemical agents, each one interacts uniquely with the inner layers of a package. If there is a mismatch between the materials used, then chemical components can migrate and degrade the adhesive layers forming tunneling, blistering, or off-odors. A successful package must make the chemical neutrality and stability between the substrate, adhesive and product absolute.

2. Barrier Protection Levels

To protect is the main mission of packaging. The primary factors responsible for spoilage, fading, and loss of flavor in most products are oxygen, moisture, and ultraviolet light. But by no means is more barrier always better; what is needed is a compromise between performance and cost. Taking into account the shelf-life required for your product, you have to apply the laminating process to come up with a rational mixing of functional films (like PET, Aluminum foil or high-barrier PE). Whether your product.

3. Structural Strength

A lovely package that breaks under the pressure of the global supply chain is a drawback. The physical strength is not only determined by the thickness of the material, but also the peel strength that holds together the laminated layers. A technical point that must be taken into account: If pressure distribution is not uniform or temperature control is not effective during the lamination process, the package can easily reach the delamination stage when subjected to squeezing, dropping or thermal cycling. Structural integrity disappears as soon as delamination happens, leading to either leaking or bursting.

4. Customer Experience

Packaging is the first moment of contact between the consumer and the brand. Today’s trends call for more than just visual attraction; they ask for a quality hint via touch. By means of modern coating and laminating techniques, manufacturers can give their products matte, velvet-touch, or even anti-scratch attributes. Nevertheless, the films used for these developments are often very vulnerable to heat and pressure. The ability to perfectly control flatness and gloss without causing any damage to the high-value coatings is the hallmark of premium packaging processing.

5. Sustainability

The global market trend is carbon reduction, and “downgauging” (the use of thinner materials) and “mono-material recyclability” have been set as the industry norms. Brands are always looking for thinner films and simpler constructions. The technical suspense, however, is that thinner materials are by nature less stable when used on high-speed production lines. This leads to a necessity of a production process with extremely high precision, which will allow rigorous tension control that will ensure that the ultra-thin substrates do not get affected by irreversible stretching or wrinkling due to small deviations in traction force.

6. Waste Costs

The profitability of a product is sometimes found in the hidden areas of the production line. In packaging processing, every unplanned downtime and every meter of material wasted directly reduce the product’s profit margin. Good packaging solutions are those that not only focus on raw materials’ unit price but also on the overall yield. Employing smarter equipment management for minimizing setup waste and ensuring quality across large batches is the invisible path of maintaining competitiveness in the era of low margins.

7. Regulatory Compliance

In the case of food, personal care, and pharmaceutical industries, safety in packaging is the most important point that cannot be compromised. Traditional solvent-based lamination processes, if not dried completely, bring the danger of leaving high VOC residues, which could result in odor problems or health risks. The Solventless Lamination process has been gaining popularity as the standard option with the elimination of solvent residue risks right at the source, thus assuring that your product complies with the most rigorous global safety and hygiene standards.

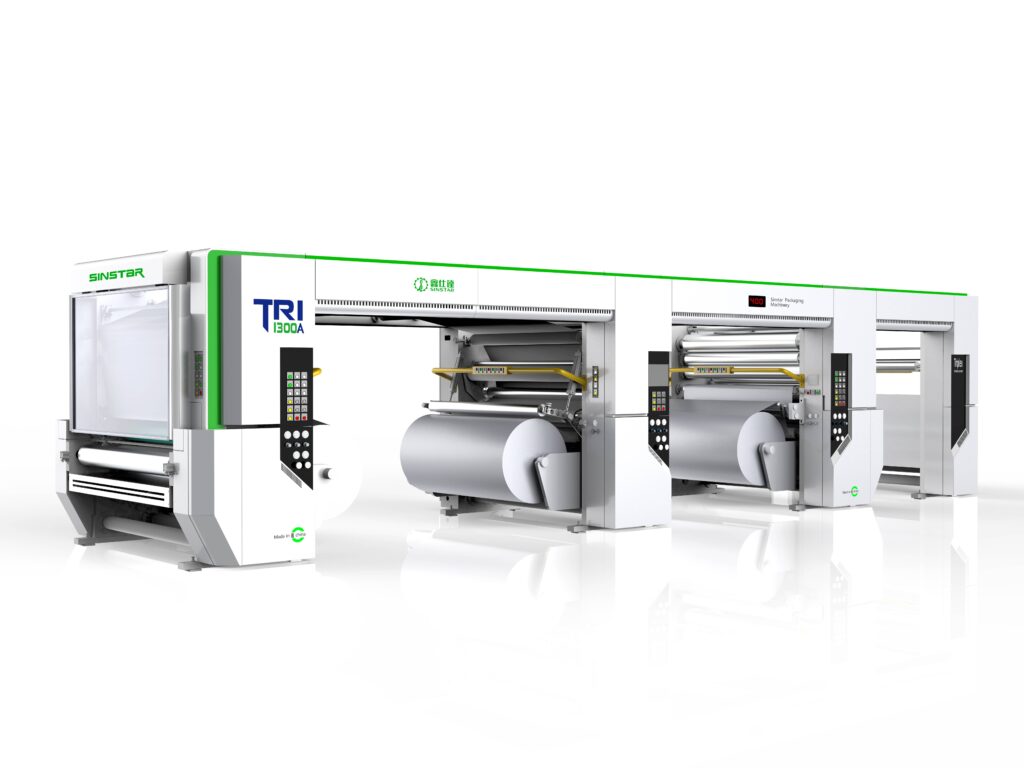

How Sinstar Can Help Your Product Packaging Success

Sinstar, as a global leader in lamination and coating technology, takes packaging in detail and hence considers the success of a package to be determined by microscopic details that are invisible to the naked eye. We do not only offer precision machinery to manufacturers but also, we are process consultants for brands where the latter gets their pathogens killed through Sinstar innovations and thus the rethinking of packaging.

The following points illustrate the Sinstar way of empowering your packaging success:

- Precision Control, Eliminating Delamination Risks: Sinstar laminators have the most advanced smart tension balancing systems among the rest in the industry. They manage ultra-thin substrates and wreaked intricate films at the same time, assuring the structure of composite stays intact even when subjected to extremely high forces.

- Setting New Standards for Green Production: The use of our original solventless lamination technology provides major cardboard companies with the capability of discarding by-products that come from solvents, letting them go even further on the eco-friendly path due to their already low energy usage and emissions.

- Superior Surface Execution: The Sinstar machines offer the ultimate support by giving the precise control over pressure and temperature that perfecting visual and tactile effects needs. E.g. High-value functional films that are frequently altered in terms of their qualities to attract customers via sight and touch can still be rendered with the exact texture and color that are desired, thus being very appealing on the shelf.

- Consultative Technical Support: Through equipment adjustments and the provision of formulas, we support you in cutting down on material waste while simultaneously increasing line speeds, thus high-quality packaging and commercial returns will not only go together but also be the case.

Would you like to improve the quality of your packaging or the efficiency of your lamination? Now is the time to get in touch with the Sinstar team who can assist you in creating the most competitive packaging solution together.