Why Film Delamination Happens and How Lamination Machines Solve It?

In flexible packaging and industrial film applications, delamination is one of the most common and most frustrating quality problems. A film that looks fine on the surface may start to peel, blister, or separate between layers during use. Once that happens, the product’s performance, appearance, and reliability are all compromised.

Understanding why delamination occurs—and how proper lamination equipment can prevent it—is essential for anyone working with multilayer films.

What Is Delamination?

In simple terms, delamination means the separation of layers in a laminated structure. When two or more films are bonded together, they are supposed to behave as a single, stable material. If the bond between layers is weak or unstable, the layers can begin to detach over time. This is known as film delamination.

In the packaging and converting industry, delamination usually shows up as:

- Layers peeling apart at the edges

- Bubbles or blisters between films

- Loss of barrier, strength, or visual quality

So when people ask “what is delaminating?”, the practical answer is: It’s when a laminated film loses its internal bonding and the layers no longer stay together as designed.

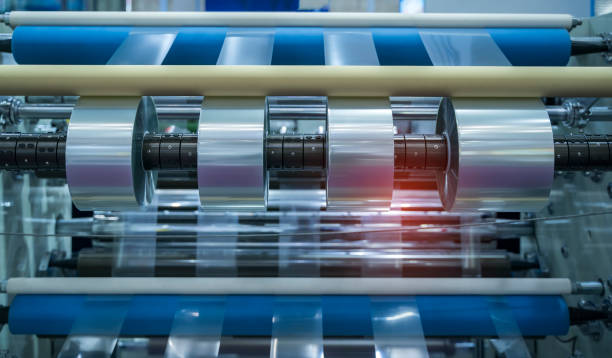

Why Multilayer Films Easily Delaminate

Multilayer films are used because no single material can do everything. One layer provides strength, another barrier, another printability, and so on. But the more layers you add, the more interfaces you create—and every interface is a potential weak point.

Common reasons multilayer films delaminate include:

- Incompatible materials that do not bond well together

- Insufficient adhesive activation during lamination

- Moisture, heat, or aging breaking down the bond over time

- Uneven pressure or temperature during the lamination process

This is why delamination of multilayer films is not just a material issue. It is very often a process control issue, and that brings us directly to lamination.

Which Lamination Parameters Cause the Most Problems

Delamination usually starts in the lamination stage. Even with good films and good adhesive, small process mistakes can lead to big bonding problems later.

The most critical parameters include:

1. Temperature Control

If the temperature is too low, the adhesive does not activate properly. If it is too high, the film may deform or the adhesive may degrade.

2. Pressure and Nip Uniformity

Uneven pressure across the width of the web leads to weak bonding zones. These zones are often where delamination first appears.

3. Web Tension Stability

Too much tension can stretch films and reduce contact quality. Too little tension can cause wrinkles and poor layer alignment.

4. Coating and Adhesive Distribution

If adhesive is not applied evenly, bonding strength will vary across the film.

In short, multilayer lamination is not just about sticking layers together. It is about controlling a set of parameters that must work together consistently.

Which Lamination Machine Capabilities Prevent Delamination

Because delamination is so closely tied to process stability, the lamination machine itself plays a decisive role.

- Precise temperature control across all heated zones

- Stable and adjustable tension systems for different film types

- Uniform nip pressure control across the full web width

- Accurate adhesive coating and metering systems

- High-speed stability without vibration or drift

A lamination machine that cannot hold these parameters steady will always struggle with delamination—no matter how good the films or adhesives are.

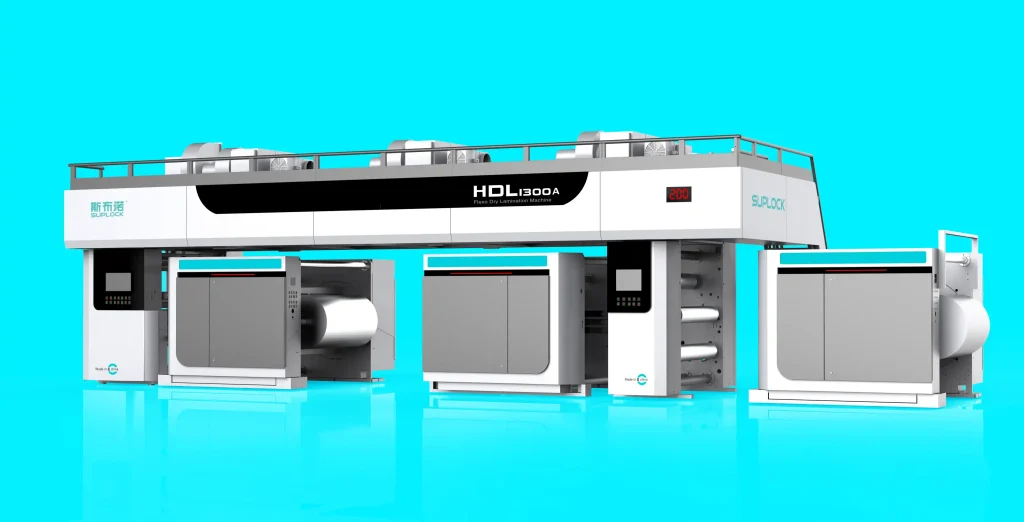

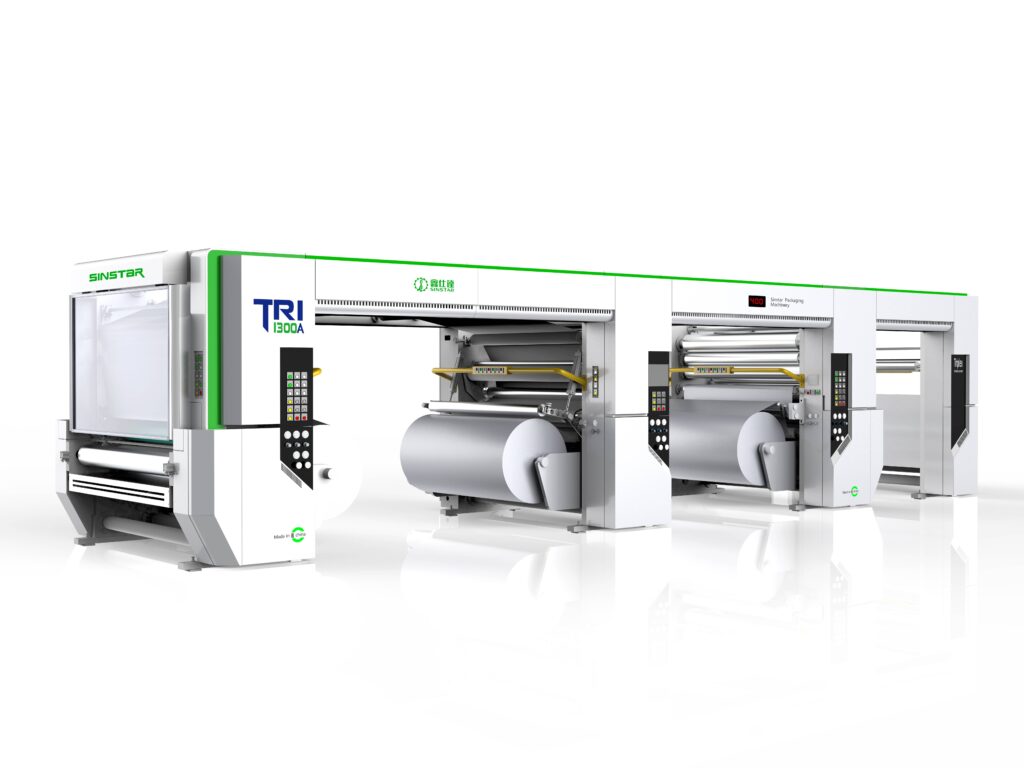

How Sinstar Lamination Machines Help You Solve Film Delamination

At Sinstar, our lamination machines are designed specifically to reduce the risk of delamination in multilayer film structures.

Here is how our equipment addresses the core causes:

1. Consistent Thermal Control

Sinstar machines use multi-zone temperature systems that keep heat distribution stable and uniform. This ensures proper adhesive activation without damaging sensitive films.

2. Intelligent Tension Management

Our web handling systems maintain constant tension from unwind to rewind, reducing wrinkles, slippage, and layer misalignment that lead to weak bonding.

3. Precision Pressure Systems

Uniform nip pressure across the web ensures every part of the film receives the same bonding force, minimizing weak points where delamination can start.

4. Stable High-Speed Operation

Sinstar lamination machines are engineered for smooth, vibration-free running, even at higher speeds. This allows customers to increase productivity without sacrificing lamination quality.

5. Process Flexibility for Different Film Structures

Whether it is packaging film, industrial film, or specialty multilayer structures, our machines can be configured to match different materials, adhesives, and thickness ranges.

Film delamination is not just a material problem—it is a lamination quality problem. In most cases, it comes down to how well the lamination process is controlled.

By combining the right materials with the right equipment, manufacturers can significantly reduce the risk of delamination in multilayer films. Advanced lamination machines are not just production tools; they are process control systems that protect product quality.

With Sinstar lamination machines, customers gain the stability, precision, and flexibility needed to produce reliable multilayer films that stay bonded—through processing, storage, and end use.