How to Choose the Right Solventless Lamination Machine: Single-Layer vs Multi-Layer

It is a major point to choose the most suitable solventless lamination machine for the packaging manufacturer who seeks to have productivity, quality, and sustainability all at the same time. As the interest in the eco-friendly solventless laminators with no VOC emissions is getting more and more intense, companies are turning their backs on the toxic solvent-based systems to diminish the impact they are making on the environment and to stay within the regulatory limits set by the authorities. In case the wrong machine model is chosen, this may result in a fall in efficiency, growth of expenses on machine maintenance, and issues related to the quality of the output that cannot be depended on and therefore may have monetary returns as a result. This reading will be a good guide for you if your choice of the machine is based on the needs of the production process, the technical qualities of the device, and the production targets that you have set.

Understanding Your Packaging Requirements Before Choosing a Machine

Before you buy a solventless lamination machine for food and pharmaceutical packaging, you need to know your production requirements. Here are some of the main factors:

- Packaging type: Are you going to produce flexible pouches, bags, or labels? Applications are different; each one needs the adhesion technique and lamination precision.

- Material Structure: Single-layer films like PET / PE or OPP / CPP and multi-layer high-barrier materials require, respectively, single-layer or multi-layer machines.

- Production volume: Calculate your mean monthly output and variability in orders to make sure the machine can meet peak demands.

Through this procedure, companies can find the best machinery and fit it into their workflow, plus cut down on the operational waste. Even for the high volume business, acquiring a high-speed solventless lamination machine for flexible packaging can still be advantageous in terms of productivity.

Single-Layer vs Multi-Layer Solventless Lamination Machines

Single-Layer Models: Cost-Effective and Simple

Single-layer solventless laminators are ideal for businesses producing standard packaging structures or low-SKU product lines. These machines are:

- Easier to operate

- Require lower initial investment

- Efficient for simple film-to-film lamination

Multi-Layer Models: Flexibility for Complex Packaging

Multi-layer solventless lamination machines are the way to go if you are looking for a high-barrier, multi-layer packaging solution. With their enhanced flexibility and adhesive efficiency, they are perfect for the industries that need:

- Food-grade or pharmaceutical-compliant packaging

- Multi-layer barrier structures

- Consistent high-quality lamination under high-speed production

When comparing the benefits of solventless lamination against solvent-based lamination, it is observed that the multilayer models make the most of the environmental compliance and the running of operations to be more efficient.

Choosing the Right Working Width for Your Solventless Laminator

The web width of a laminator affects the efficiency of the process, the speed of production and the versatility to carry various products. The normal ranges are:

- Narrow-width machines: 800–1000 mm

- Medium-width machines: 1000–1200 mm

- Wide-width machines: 1300 mm and above

Wide-web laminators are ideal for businesses pursuing large-scale production and energy saving solventless lamination lines for large-scale production, whereas narrow-width models suit smaller batches or niche products.

Matching Machine Speed to Production Goals

High-speed machines can significantly increase output, but speed must align with your production goals. Consider:

- Effective production speed vs nominal speed

- Material tension control at high speeds

- Adhesive curing and layer consistency

Selecting the correct speed means that the work will be done most efficiently and the quality will also not be sacrificed. The application of a high-speed solventless lamination machine in the flexible packaging industry is sure to be a profitable move for the medium to large-scale operations provider.

Automation Level: From Manual to Fully Automated Solventless Laminators

Manual and Semi-Automatic Systems

Manual or semi-automatic laminators are suitable for small businesses or first-time adopters of solventless technology. They require hands-on operation but offer lower upfront costs.

Fully Automated Systems with Digital Control

Fully automated laminators provide:

- Automatic adhesive application

- Digital tension control for consistent lamination

- Online monitoring of production parameters

- Reduced downtime and higher quality consistency

Businesses investing in automated solventless lamination equipment with digital tension control gain long-term efficiency and scalability.

Adhesive Efficiency and Consistent Quality

Adhesive performance is critical for reliable lamination, especially in multi-layer or high-speed applications. Consider:

- Precise adhesive dosing systems

- Compatibility with different film materials

- Stable performance across production shifts

A multi-layer solventless lamination machine that is high in adhesive efficiency will deliver quality consistency and reduced waste that will drive profitability enhancements.

Maintenance, Operator Training, and Long-Term Costs

A machine’s total cost of ownership goes beyond the initial purchase price. Businesses should evaluate:

- Maintenance complexity and frequency

- Operator training requirements

- Downtime risk and spare parts availability

A solventless laminating machine maintenance and operator training guide can help ensure smooth operation and longevity, maximizing ROI.

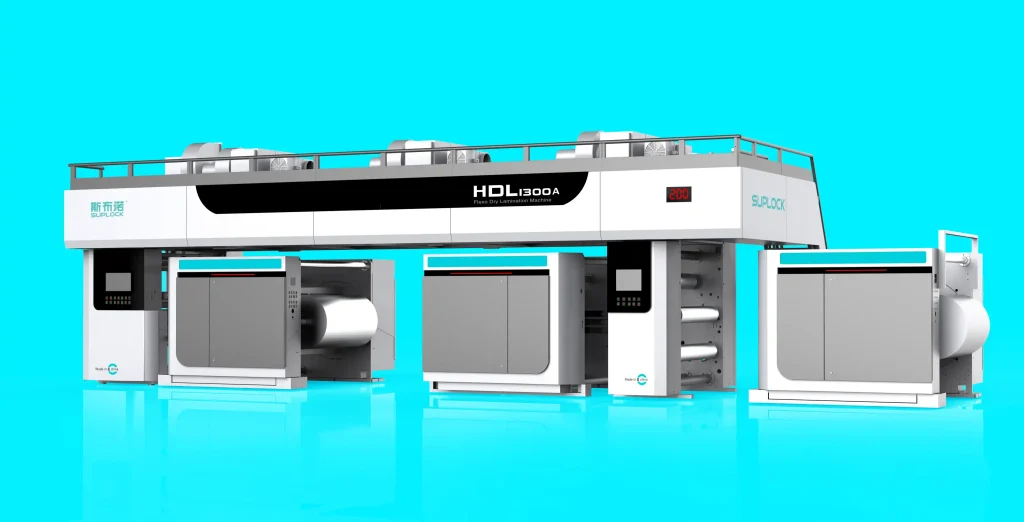

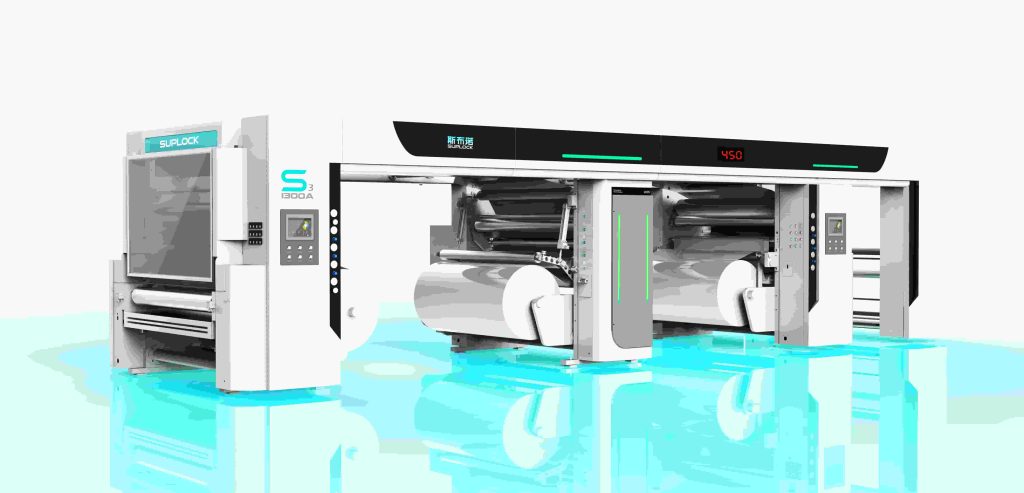

SUPLOCK Series: Matching Models to Your Business Scenario

The SUPLOCK high-end solventless laminator series offers a variety of configurations for different production needs:

- Single-layer models for standard flexible packaging

- Multi-layer models for complex, high-barrier applications

- Wide web options for large-scale production

- High automation for precision and efficiency

SUPLOCK machines are created keeping in mind sustainability, as the company is the first to adhere to environmentally friendly solventless laminator standards with zero VOC emissions. There is a possibility for enterprises to connect a certain model to the production wish, taking the same amount of time into account as they would for the quality and the cost.

How to Quickly Choose the Right Solventless Lamination Machine

To make the selection process easier, the decision matrix below shows that a job wraps business scale, product difficulty, and automation needs. It then quickly mops out the most appropriate solventless lamination machine.

| Business Scale | Product Structure | Recommended Machine Type | Automation Level | Key Considerations |

| Small/Medium | Single-Layer | Single-Layer Laminator | Manual/Semi-Automatic | Low cost, simple maintenance |

| Medium/High | Multi-Layer | Multi-Layer Laminator | Semi/Fully Automated | High efficiency, consistent quality |

| Large | Multi-Layer, Wide Web | Wide Web, Fully Automated | Fully Automated | Energy saving, high-speed, scalability |

FAQ: Solventless Lamination Machine Selection

Q1: How do I choose between single-layer and multi-layer laminators?

A1: Single-layer machines are economical for standard packaging, multi-layered machines, on the other hand, are more preferable to be used in a complex or high-barrier packaging condition.

Q2: Is a high-speed solventless laminator suitable for small factories?

A2: Only if production volume justifies the investment; otherwise, narrow-width or semi-automatic models may be more cost-efficient.

Q3: What automation level is recommended for food packaging?

A3: Fully automated systems with digital adhesive and tension control ensure consistent quality and compliance with food safety standards.

Q4: How does solventless lamination reduce energy and VOC emissions?

A4: Solventless laminators eliminate drying ovens required in solvent-based systems, reducing energy use and VOC emissions, making them more environmentally friendly.