Introduction

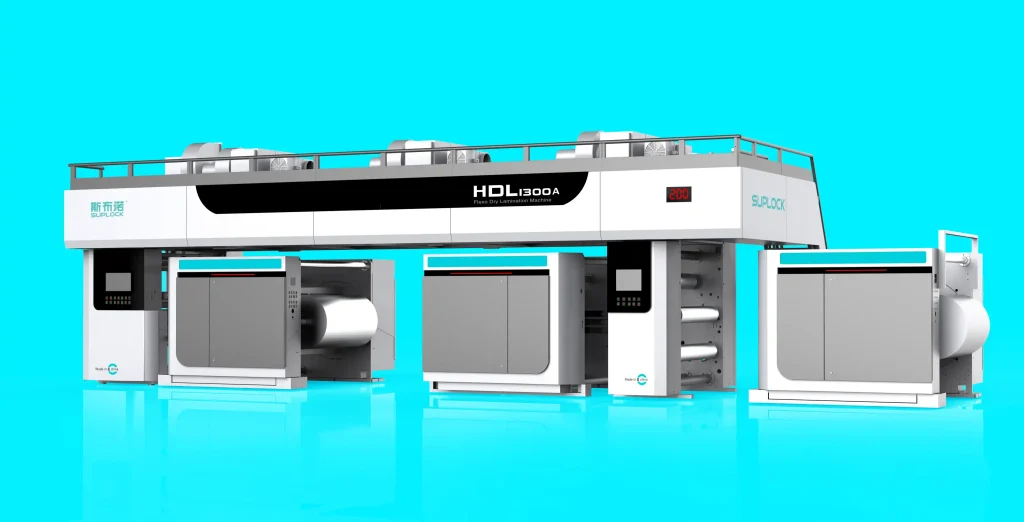

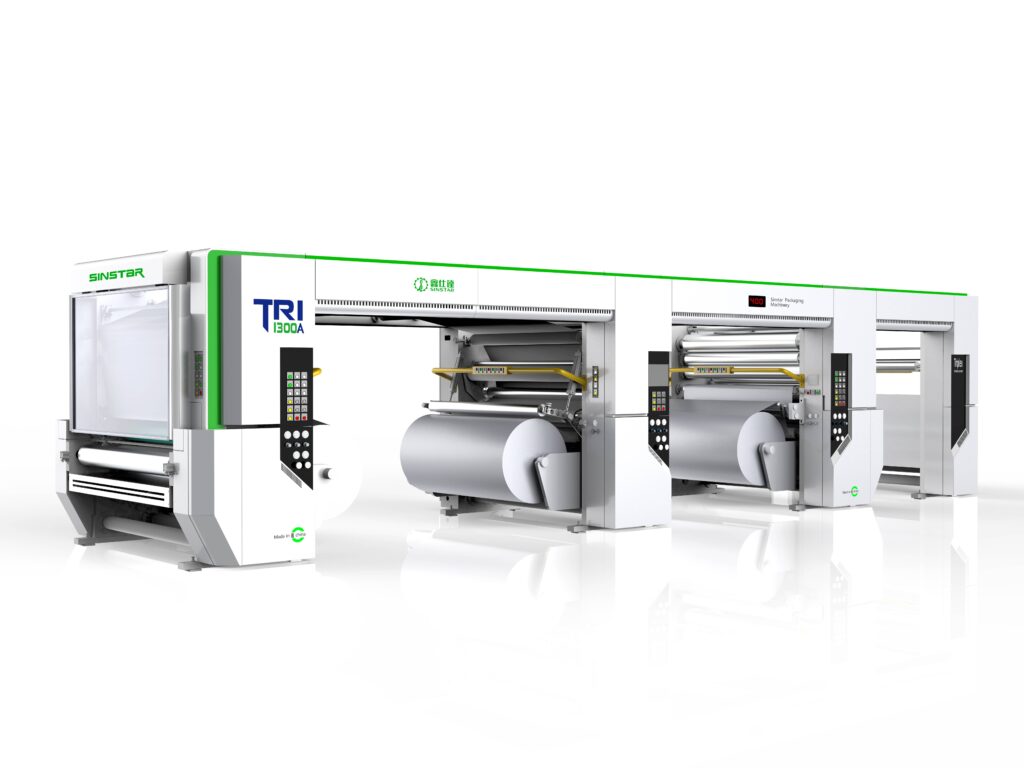

Our Quadplex Solventless Laminating Machine supports multi-layer laminating film, 4-in-1 laminate molding and laminate molding kit four in one, and many other multi-layer composites.

With the advanced four-layer composite structure, the machine provides a four-in-one laminate molding simple solution, which can complete the lamination of multiple materials in one run. While significantly increasing production capacity and reducing material waste, it is an efficient and economical choice for modern flexible packaging production.

Main Advantages

- Four-layer lamination, one machine replaces four, efficiency increased by 4 times

- Not only improves efficiency but also saves electricity and labor costs

- Digital tension control technology with 500 sets of order management capabilities

- Completely resolves the pinhole issue for 006 aluminum foil

Applications

The Quadplex Solventless Laminating Machine is designed for high-performance multilayer lamination, supporting 2–4 layer composite structures in a clean, solvent-free process. It is widely applied in the following areas:

1. Flexible Packaging

Used for food, beverage, liquid, household, and pharmaceutical packaging, including snack pouches, coffee bags, frozen food packaging, and medical consumable pouches. Suitable for complex multilayer flexible packaging structures with high bonding strength and safety requirements.

2. High-Barrier Films

Ideal for producing moisture-, oxygen-, and aroma-resistant composite films. Common structures include PET/AL/PE, BOPP/PE, PET/CPP, as well as metallized films and paper–foil–film laminations.

3. Functional and Technical Materials

Applied in functional films and technical textiles such as waterproof and windproof fabrics, protective clothing, and medical isolation or filtration materials, where solvent-free lamination is required.

5. Electronic and Industrial Films

Suitable for precision lamination of industrial and electronic films, including protective, insulating, and shielding materials requiring clean and stable bonding.

6. Paper-Based and Specialty Composites

Supports lamination of lightweight paper with films or foil for premium packaging, decorative materials, and specialty composite applications.

Specification of Quadplex Solventless Laminating Machine

| Maximum laminate speed | 450 m/m |

| Maximum laminate width | 1350 mm |

| Maximum unwinding diameter | 800 mm |

| Maximum rewinding diameter | 800 mm |

| Material loading mechanism | shaftless loading |

| Reel diameter | 3+6 inches |

Related Solventless Laminators

FAQ

Have Other Questions?

Please fill in the following form, we will respond your request in 24 hours.