EU PPWR 2025/40 Guide for Solventless Lamination Adhesives

Every manufacturer prefers solventless lamination adhesive as it is more suitable for eco-friendly food hybrid packaging. It is very environmentally sustainable as well as high-powered, leading to a preference for producers who wish to lower the levels of volatile organic compound (VOC) pollution. However, the recent changes in the EU’s regulatory framework have brought with them tough demands that impact the way these adhesives are made, used, and certified.

The packaging industry has received its defining moment through the EU(2025/40) Packaging and Packaging Waste Regulation(PPWR), which started its enforcement on February 11, 2025. The regulation will make most of its requirements compulsory starting August 12, 2026, when it replaces the 94/62/EC directive, which had been in place before. The PPWR standard requires manufacturers of solventless lamination adhesives to adjust both their material choices and production methods because it establishes composition standards, together with recyclability requirements and performance standards.

PFAS Restrictions: Eliminating “Forever Chemicals”

Perhaps the harshest area to handle in PPWR compliance is that of PFAS (per- and polyfluoroalkyl substances) regulations. While commonly used in high-performance adhesives to improve flow characteristics, chemical resistance, and durability, PFAS compounds are now under intense discussion regarding their environmental persistence and health consequences.

Under PPWR, effective August 12, 2026, the limits for PFAS in food-contact packaging are as follows:

- Single PFAS substance: less than 25 ppb

- Total PFAS (excluding polymers): less than 250 ppb

- Total fluorine content: must not exceed 50 ppm

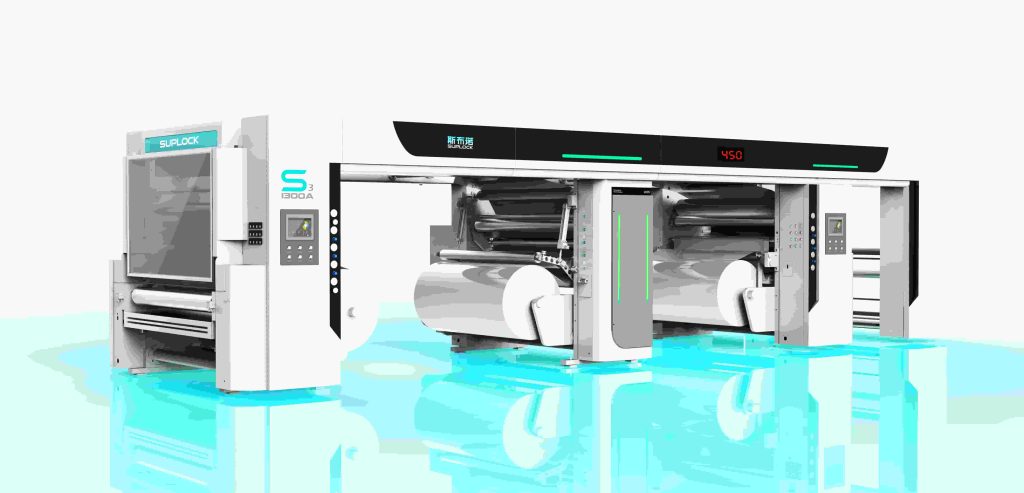

With regards to solvent-free lamination adhesive manufacturers, this involves reformulation to include PFAS-free claims and Total Fluorine (TF) testing to confirm there are no potential levers. The removal of fluorinated additives would present traditional formulations for adhesives with difficulties in achieving the same level of flow, adhesion, and chemical resistance without PFAS. This has inspired innovation in terms of additives, namely advanced solvent less lamination machines for superior coating control.

DfR (Design for Recycling) & Performance Grades

One novel concept that is proposed by PPWR refers to the Design for Recycling (DfR) concept and its corresponding performance classes A-E. While any conventional packaging could be evaluated chiefly in terms of its materials, the total system has to be taken into account now, where adhesion is recognized as a vital component affecting recyclability.

Key grading requirements include:

- By 2030: only packaging with grades A, B, or C can enter the EU market

- By 2038: only grades A or B will be accepted

This has significant implications for solvent-less lamination adhesives; failing to implement adhesives that help with recycling or that do not respect material integrity will lower the packaging’s quality. Therefore, manufacturers are coming forth with easy-peel, monomaterial-compatible, or mechanically and chemically recoverable adhesives. This trend is being accompanied by an increasing market adoption of solventless lamination machines, as they can meter adhesives down to a very precise amount and will facilitate proper adhesion of the materials, reducing material incompatibility during recycling.

PAA Migration Monitoring: Ensuring Safety

Primary aromatic amines (PAA) have long been a concern in polyurethane-based adhesives. Under the new PPWR, regulations surrounding PAA migration have become more precise, reflecting the EU’s focus on both consumer safety and supply chain efficiency.

The new requirements include:

- PAA migration below 0.01 mg/kg before the adhesive leaves the factory

- Ultra-low monomer (ULM) requirement: isocyanate monomer content below 0.1%

With the limit, the adhesive remains food safe, no matter how severe the storage conditions become. It is essential for manufacturers to properly optimize the drying time and minimize chemical reactions with the solvent-less lamination equipment for fast curing, better adhesion, and minimal residual monomer content.

Mineral Oil Restrictions (MOAH/MOSH)

Food-contact adhesives in their pure form may not have any mineral oil, yet the regulations define stringent conditions for the usage of raw materials procured for food-contact applications in controlling MOAH (aromatic) and MOSH (saturated) substances. The customary limits for MOAH contamination in food-contact applications lie between 0.5-2 mg/kg.

For solventless lamination adhesive manufacturers, this requires rigorous raw material screening, including:

- Plasticizers

- Resin carriers

- Additives or residual solvents

Ensuring supply chain purity is critical to prevent mineral oil contamination, which could compromise both regulatory compliance and brand safety.

Strategic Implications for Adhesive Manufacturers

The PPWR 2025/40 represents both a challenge and an opportunity. To remain competitive in the EU market, solventless lamination adhesive manufacturers should:

- Reformulate adhesives to meet PFAS-free standards.

- Develop adhesives compatible with DfR performance grades, supporting recyclable packaging.

- Optimize curing and monomer control to ensure low PAA migration.

- Verify all raw materials for mineral oil contamination to maintain compliance.

- Invest in advanced solvent less lamination machines to achieve precise coating, uniform layer thickness, and improved recyclability.

Thus, addressing these areas may not only ensure that the manufacturers meet EU regulations but also strengthen their position in the market as a sustainable and safe solution to packaging.

FAQ: PPWR Compliance for Solventless Lamination Adhesives

Q1: When will PPWR 2025/40 compliance be mandatory for adhesives?

A1: Most provisions, including PFAS restrictions and recyclability requirements, will become mandatory on August 12, 2026.

Q2: What does PFAS-free mean for solventless adhesives?

A2: Adhesives must contain less than 25 ppb of any single PFAS substance, less than 250 ppb total PFAS, and total fluorine must not exceed 50 ppm.

Q3: How does DfR grading affect adhesive selection?

A3: Adhesives must not compromise packaging recyclability. Grades A, B, or C are required by 2030, and grades A or B by 2038.

Q4: How can manufacturers minimize PAA migration?

A4: Using fast-curing adhesives, ultra-low monomer formulations, and precise control via solvent less lamination machines ensures PAA migration below 0.01 mg/kg.

Q5: Are mineral oil limits relevant to adhesives?

A5: Indirectly. Raw materials must be free of MOAH/MOSH contamination to maintain food-contact safety and PPWR compliance.