How Flexible Pouch Packaging Is Made: The Role of Lamination Technology

In the food, pharmaceutical, and daily chemical industries, the role of packaging is undergoing a quiet but significant transformation. A growing number of products are shifting away from traditional glass bottles, metal cans, or rigid plastic containers toward Flexible Pouch Packaging. This shift is no accident, it is the direct result of continuous advancements in material science and manufacturing processes.

On the surface, a flexible pouch may appear to be nothing more than a lightweight, easy-to-open container. However, the true determinants of its performance and reliability lie not in the “pouch shape” itself, but in the material structure and lamination processes behind it. Understanding how these pouches are manufactured provides a clearer perspective on the vital value that lamination technology brings to the entire packaging ecosystem.

What is Flexible Pouch Packaging?

Flexible pouch packaging refers to a packaging form based on multi-layer flexible film materials, which is made through printing, lamination and bag-making processes. Common types include:

- Stand Up Pouch Packaging

- Flat Pouch or Sachet

- Spouted Pouch

Compared with traditional rigid packaging, flexible pouches are more flexible in terms of material usage, transportation efficiency and structural design. This is also an important reason why it is widely adopted in the field of food packaging, especially in snack foods, condiments, liquid and semi-solid products.

Material Structure of Flexible Pouches

In food packaging applications, a single material often fails to simultaneously meet multiple requirements such as barrier properties, strength, and heat-sealing performance. Therefore, most flexible food bags will adopt a multi-layer lamination structure. Each layer of material is not repeatedly stacked but serves different functions.

Outer Layer

Usually used as the printing layer, common materials include PET or BOPP. This layer is mainly responsible for visual effects, heat resistance and basic protection against the external environment.

Barrier Layer

Used to block oxygen, moisture and light, common materials include aluminum foil, VMPET or EVOH. It is directly related to the shelf life and stability of food.

Inner Sealant Layer

In direct contact with the contents, PE or CPP is usually adopted to achieve reliable heat sealing and meet food contact safety requirements at the same time.

How do materials match specific products?

The requirements for packaging vary among different products. Foods with a longer shelf life and sensitivity to oxygen often require higher-grade barrier structures. However, for liquid or high-temperature filled products, higher requirements are placed on the inner layer materials and lamination strength. These differences will all be reflected in the material combination and lamination methods.

Lamination Technologies Used in Pouch Packaging

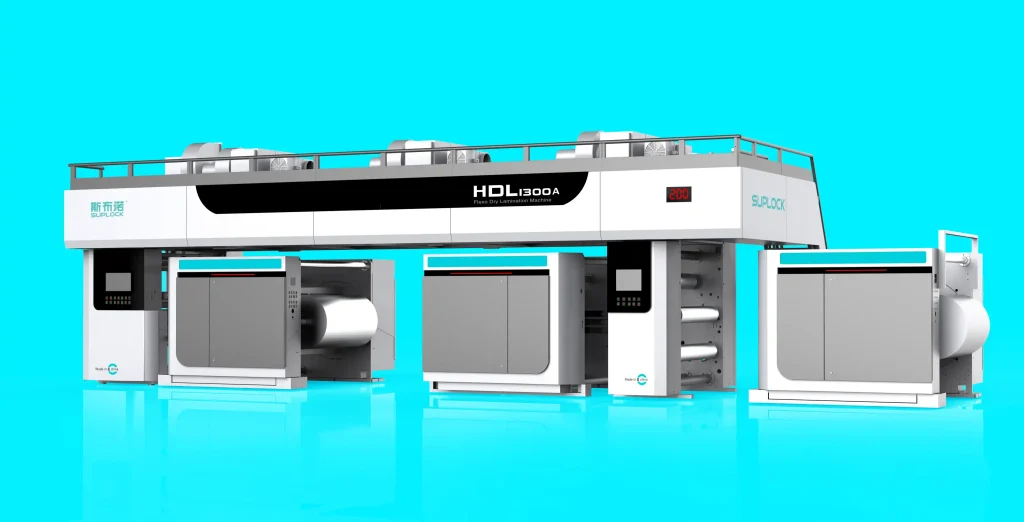

Dry Bond Lamination

Dry lamination is the most widely used lamination method. The basic principle is to first apply the adhesive on the surface of the substrate, dry it in an oven, and then heat-press it together with another layer of material.

This method has a wide range of applications and high lamination strength, and can meet the requirements of most food packaging structures.

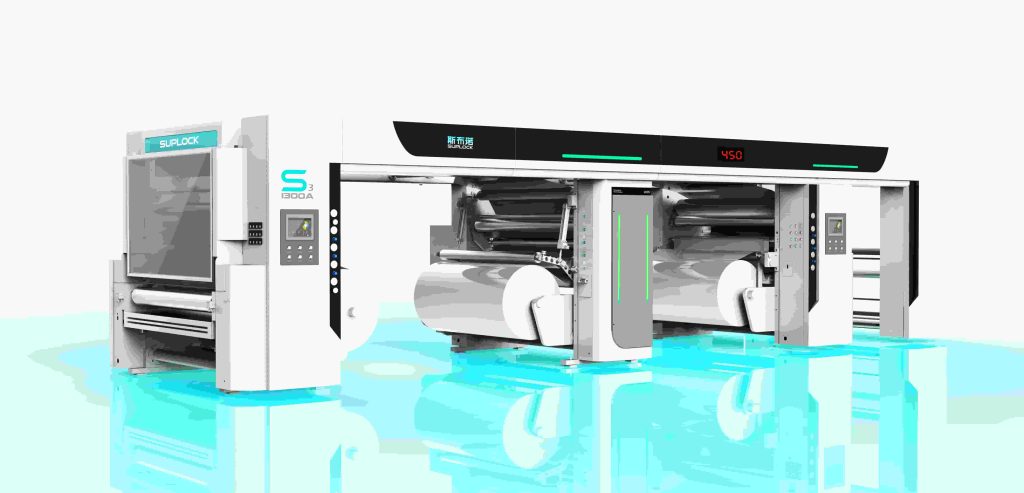

Solventless Lamination

Solventless lamination uses specially formulated adhesives, eliminating the need for solvent evaporation and prolonged drying. Compared with traditional techniques, it has obvious advantages in terms of environmental protection, energy consumption control and food safety.

For this reason, solventless lamination is becoming an important development direction in the field of food packaging, but it also puts forward higher requirements for the coating accuracy and operational stability of laminating equipment.

Extrusion Lamination

Extrusion lamination achieves bonding by casting molten resin directly between two layers of material. This method is commonly used for packaging with specific structural requirements and demands a high degree of compatibility between the equipment and the process.

Wet Lamination

Wet lamination is mainly applied to the lamination of paper-based materials and aluminum foil, and still has application value in some paper packaging or special structures.

Stand Up Pouch Packaging: Lamination Requirements and Challenges

Among all forms of flexible pouches, stand-up bags have particularly prominent requirements for lamination quality.

The bottom of the standing bag needs to bear the weight of the contents, and the lamination structure must have stable peel strength and consistency. If the lamination is uneven, problems such as bubbling and delamination are likely to occur, which directly affect the yield and safety of use.

For food stand up pouch packaging, the lamination quality not only affects the appearance but also determines the overall performance of the packaging during transportation, storage and shelf life.

The Complete Manufacturing Process of Flexible Pouches

Printing

Usually, gravure or flexographic printing is adopted to print the pattern on the inner side of the outer material. The inner printing method helps protect the pattern and provides a stable foundation for subsequent lamination.

Laminating

Through appropriate lamination processes, materials of different functional layers are stably combined. This stage directly determines the structural performance of the final packaging.

Curing

The laminated film needs to be cured for a certain period of time to allow the adhesive to fully react and ensure the peel strength and structural stability.

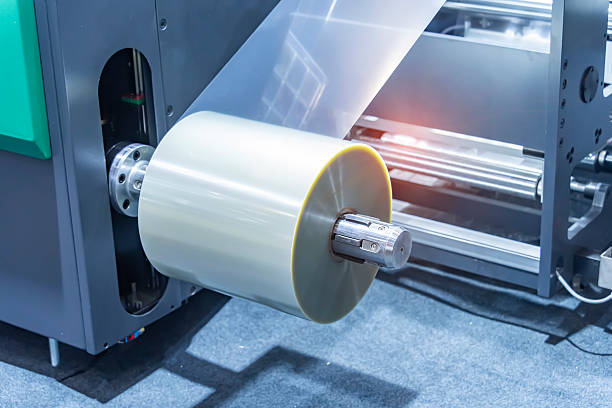

Slitting

Cut the large roll of lamination film into small rolls according to the bag-making size to ensure the smooth progress of the subsequent bag-making process.

Pouch Making

The folding, heat-sealing, and cutting are completed by the pouch-making machine, with zippers or spouts added as needed. This process operates in seamless coordination with the entire pouch packaging machine production line.

Why Is Lamination Technology The Key To The Manufacturing Of Flexible Pouches?

In the manufacturing process of flexible pouches, lamination is not an optional step but a core procedure that integrates different functional materials into a whole. Through the lamination process, films with originally different properties are stably combined together, making the packaging possess barrier properties, mechanical strength and processing adaptability simultaneously in practical use. If the lamination quality is unstable, even if the material selection is reasonable, the final product will be difficult to achieve the expected effect.

Stable lamination quality not only helps to achieve complex structural designs but also ensures consistent performance of brand packaging across different batches, which is of great significance for long-term market operations.

Through reasonable lamination structure design, flexible pouches can achieve:

- More reliable barrier performance

- Higher puncture resistance and compressive strength

- Matte, glossy or special touch and other appearance effects

- It is suitable for special application scenarios such as high-temperature sterilization and frozen storage

The realization of these performances cannot be achieved without the support of stable and controllable lamination processes.

Conclusion

From material selection to the final pouch formation, every link in the flexible packaging chain is interconnected. Among these, lamination technology does more than just bond different materials, it determines the overall performance and stability of the entire package.

As environmental regulations tighten, mono-material structures are becoming a major development trend in flexible packaging. At the same time, achieving material thinning—while maintaining high performance—is a critical path toward reducing carbon emissions.

Furthermore, smart packaging—which integrates QR codes, traceability systems, or functional materials—is steadily moving into practical application phases.For packaging manufacturers aiming to continuously improve product quality and production efficiency, selecting the right lamination solution is a vital foundation for long-term competitiveness.