Why Solventless Laminating Machine Drives Flexible Packaging Boom

Driven by the rapid pace of urbanization, changing consumer behaviors, and the growth of the e-commerce, food, and pharmaceutical industries, the global packaging sector is changing at an increasing rate. Newly flexible packaging makes a unique opportunity in terms of sales/market profit. There are so many options for creating flexible packaging, and it’s sustainable for our environment too. Environmentally friendly, light, and flexible products excel. Packaging products are greatly sought after flexibles that’s for sure, thus packaging manufacturers are tirelessly working towards finding efficient, faster, and more affordable technology that will allow increased flexibility packaging for consumers.

Because of the many benefits of improved technology, the packaging industry is gaining market from the improved technology, the industry is gaining…Restating. One of these technologies is the solventless lamination technology, and its accompanying laminators. Solventless lamination is gaining strong market preference among packaging companies looking to reduce their carbon footprint, enhance productivity, and comply with the world’s packaging safety standards. For this reason, the flexible packaging lamination market is experiencing strong growth in demand for the solventless technology.

Part 1: What Caused the Boom in Flexible Packaging?

1. Consumer Preference for Lightweight and Sustainable Packaging

Packaging that opens easily and fits easily into purses or backpacks is becoming the norm that consumers are looking for. Flexibles is the answer to this demand as they use less material, have lower transport emissions and recyclable options.

2. Rapid Growth of Food and Beverage Sectors

Increasing awareness of food products among consumers, together with an increasing demographic population always needing food on the go, and food that does not deteriorate, is driving demand for portable and shelf-stable food. Companies are now trying to find flexible packaging as it keeps products fresh and has great printability. Flexible packaging has become the industry standard for snack food packaging and ready-to-eat meals.

3. E-Commerce Packaging Needs Driving Stronger, lighter Materials

E-commerce packaging must be cost effective to ship and durable. Flexible packaging is light, durable, and has excellent barrier properties to moisture, oxygen and UV light.

These trends indicate flexible packaging is the answer. Converters and packaging manufacturers have the opportunity to modernize their production.

Part 2: The Distinct Advantages of Solventless Laminating Technology

1. Complete Regulatory Adherence and Zero Emissions

The process does not involve the use of solvents as the adhesive bonds used contain 100% solid materials. Since the process does not use solvents, there is no chance of giving off VOC emissions, there is no need for the recovery system for solvents, and as a result, you will more easily comply with international regulations as they become more and more stringent. Within the food packaging, the process lessens the chances of having solvents left behind as well, not only improving safety for the customers but also improving safety overall.

2. Decreased Operating Expenses and Energy Usage

In contrast to solvent-based laminators that necessitate lengthy drying furnaces, a solventless laminating machine operates at significantly lower energy levels. Manufacturers recognize substantial cost savings through the elimination of:

- High-Temperature Dehydration

- Storage, management, and reclamation of solvents

- Canister disposal and refuse management

This directly enhances profitability for producers of large-scale flexible packaging.

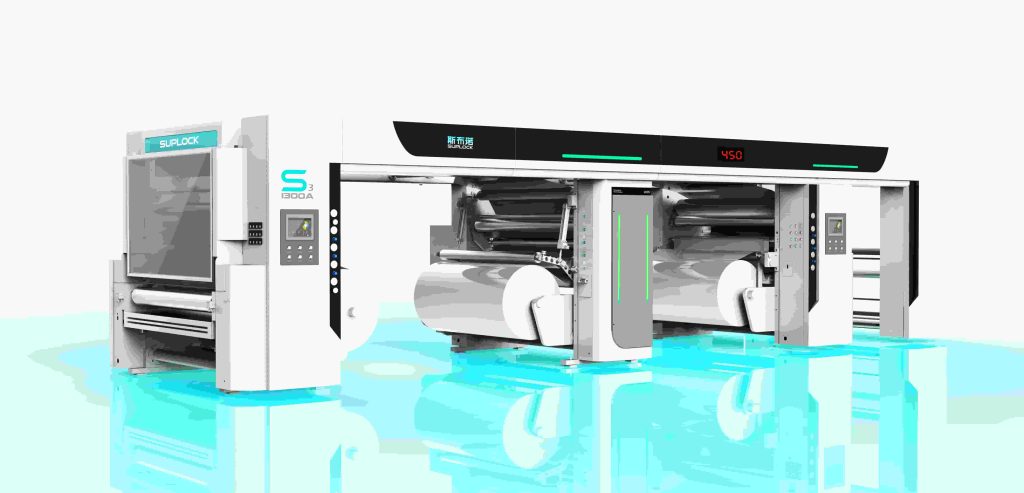

3. Enhanced Efficiency and Consistent High-Speed Performance

Many contemporary solventless laminators operate at velocities ranging from 400 to 600 meters per minute, allowing converters to attain exceptional throughput. The rapid curing characteristics of solventless adhesives facilitate the reduction of delay and render the process appropriate for just-in-time manufacturing approaches.

Part 3: Increased Investment: Adoption of Solventless Laminating Machines.

1. Global Transition from Solvent-Based to Solventless Systems.

Environmental rules, carbon reduction targets, and consumer demand are all pulling businesses away from old solvent-based laminating techniques. As sustainability becomes a corporate concern, solventless laminating machines have emerged as the preferable investment for both established converters and new manufacturing facilities.

2. High return on investment (ROI).

Companies frequently recoup their investment considerably faster than with traditional lamination systems due to the simpler process flow, decreased energy usage, reduced maintenance, and removal of solvent-related dangers. The long-term operating savings and decrease in production bottlenecks make solventless equipment extremely appealing.

3. Rapid expansion in Asia-Pacific markets.

Asia-Pacific, particularly China, India, Vietnam, and Indonesia, has emerged as the region with the fastest growth in flexible packaging manufacturing. Rising food production, expanded retail sectors, and increased export demand have resulted in significant investments in cutting-edge lamination machines. Many of these regions’ factories have chosen to adopt the use of solventless systems in an effort to meet the requirements of green manufacturing and digital transformation.

Part 4: The Use of Solventless Lamination in Flexible Packaging

1. Food Packaging: Due to its safety and cleanliness, solventless adhesives are now used in the vast majority of laminated flexible packaging for snacks, confectionery, frozen foods, coffee, and ready meals.

2. Pharmaceutical and Medical Packaging: Solventless lamination, with its high barrier qualities and contamination-free manufacture, is perfect for medicine pouches, blister pack lidding, and sterilized product packaging.

3. Personal Care and Home Goods: Solventless laminated films provide good sealability and durability for shampoo sachets, detergent pouches, and other common items.

Across all applications, the growing preference for flexible packaging lamination drives up market demand for solventless laminators.

Part 5: Technological Innovations for Solventless Lamination

1. Digital automation and precision coating.

Newer systems have improved digital controls, closed-loop tension management, and automatic coating weight adjustment. These advances reduce human mistake while ensuring consistent product quality.

2. Highly Effective Solventless Adhesives

Manufacturers are creating adhesive systems that cure faster and have a lower viscosity, primarily for high-speed production. These adhesives are suitable for a wider variety of substrates, including metallized films and high-barrier structures.

3. Smart Factory Connectivity

The integration of solventless lamination lines with MES systems, cloud analytics, and real-time quality monitoring is transforming them into intelligent production modules capable of predictive maintenance and automation.

Part 6. Future Outlook: Solventless Lamination as the Industry’s Growth Engine

The global shift towards sustainable packaging is becoming more prominent. Because of government VOC regulations, along with brand owners’ demands for low emission packaging and consumer requests for safer packaging. Solventless lamination process is set to be the most important process for the production of flexible packaging.

With flexible packaging’s increasing adoption within the food, pharmaceutical, personal care, and industrial markets, the buying trend for new solventless laminating machines should also continue to grow. Market predictions indicate that, within the next ten years, the innovation of packaging systems will largely depend on the application of solventless lamination technology.

Last Words

The increase in demand for flexible packaging around the globe is driving interest in technologies for solventless laminations and creating new opportunities. The laminators work with zero emissions and operate at lower costs. They are easy to operate and work well for high-speed runs. Because of this, large manufacturers across the globe are viewing them as essential pieces of equipment.

The drive for laminating flexible packaging to be more sustainable and efficient in the future will rely largely on the technological advancements made in solvent-free laminating processes.