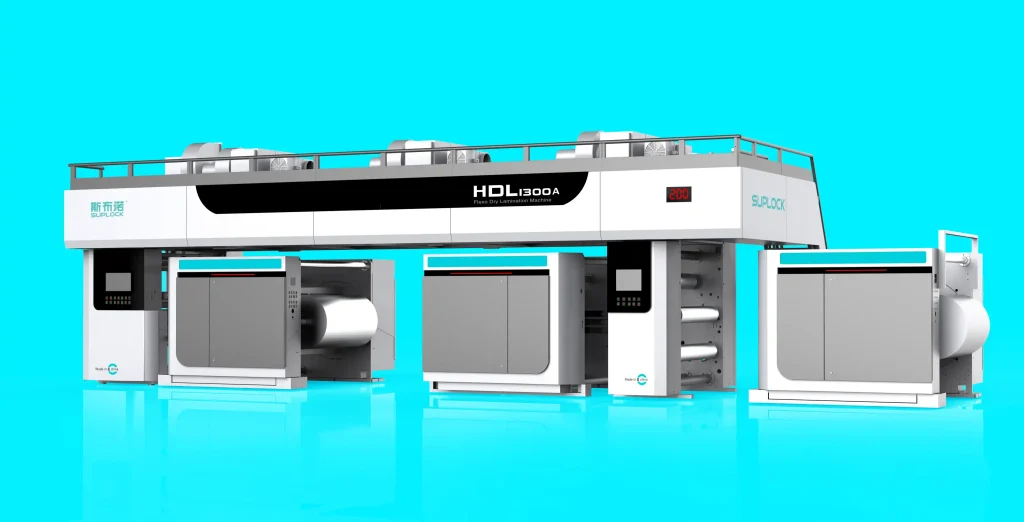

MO Insulation Material Laminating Machine

MO insulation film laminating machine is a specialized equipment designed for laminate insulation and producing high-quality laminated insulation. It efficiently bonds various films for flexible electrical insulation with substrates to create durable flexible electrical insulation materials, widely used in the electronics and electrical industries.

Applicable substrates: DMD insulation paper, NHN insulation paper, etc

Features of Solventless Insulation Laminating Machine

As advanced insulation laminating machine manufacturer,our laminator supports simultaneous coating on both sides of the middle layer, ensuring precise and uniform lamination for flexible electrical insulation materials. Featuring shaftless unwinding and rewinding, it allows for easy loading and unloading of insulation films, increasing operational efficiency. With a lamination speed of up to 100 m/min, it outperforms traditional solvent-based systems by up to 5 times.

Suitable for processing a wide range of films for flexible electrical insulation, MO laminating machine is perfect for manufacturing laminates for flexible electrical insulation and high-performance flexible electrical insulation products.

Specification of Solventless Insulation Laminating Machine

| Maximum laminate speed | 120 m/m |

| Maximum laminate width | 1350 mm |

| Maximum unwinding diameter | 800 mm |

| Maximum rewinding diameter | 800 mm |

| Material loading Mechanism | Shaftless loading |

| Reel diameter | 3+6 inches |

More Details

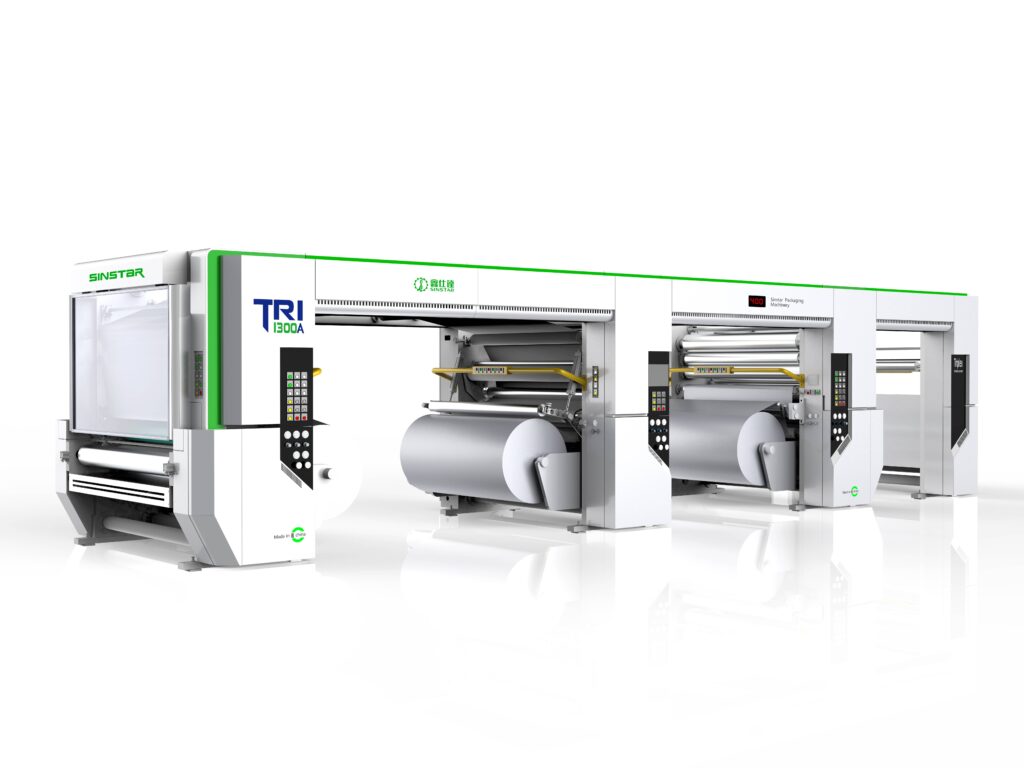

Related Solventless Laminators

Get Free Quote

Please fill in the following form, we will respond your request in 24 hours.