Why Sustainable Shrink Sleeve Packaging Depends on Solventless Lamination?

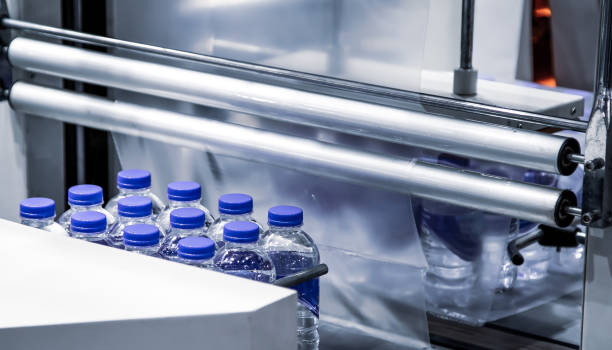

When the Packaging industry is pursuing a green transformation, Shrink Sleeve Packaging, with its 360° visual appeal and perfect fit to irregular-shaped bottle bodies, has become a powerful tool for brand marketing.

However, with the global increase in requirements for carbon footprint and environmental compliance, a core consensus has emerged within the industry: the realization of sustainable sleeve packaging does not lie in the accumulation of materials, but in the choice of manufacturing paths – especially the reliance on Solventless Lamination processes.

What is Sustainable Shrink Sleeve Packaging?

Before delving into the technology, we need to clarify a misunderstanding: not all labels that use eco-friendly materials can be called sustainable labels. A truly sustainable solution that conforms to future trends must meet the following three indicators:

- Environmental compliance: Are the VOCs emissions during the production process approaching zero? Can it pass the increasingly strict environmental protection audits?

- Safety in use: Especially in the food, dairy and healthcare industries, can the packaging eliminate the odor or migration risks caused by solvent residues and ensure the purity of the contents?

- Commercial feasibility: Can this process support large-scale industrial production while ensuring lower energy consumption and higher efficiency?

If a packaging solution, although made of degradable materials, has a high energy consumption and high pollution production process, it is still unqualified in the life cycle assessment (LCA).

Why Shrink Sleeve Packaging Need Lamination Process?

Many people think that shrink sleeve packaging are just a thin layer of plastic film, but this is not the case. To survive in complex production line and shelf environments, high-quality shrink shrink sleeve packaging typically adopt multi-layer composite structures.

- Performance balance: It is difficult for a single material to simultaneously achieve high shrinkage rate, high definition, excellent printing performance and tensile strength.

- Printing protection: To prevent the label from losing ink during transportation and friction, the ink is usually printed between two layers of film (inner printing), which requires the two layers of film to be combined through a lamination process.

Therefore, the composite process is not an option but a physical prerequisite for the existence of shrink sleeve packaging. Since lamination is inevitable, the choice of this “gluing” method directly locks in the environmentally friendly background color of the label.

Limitations Of Traditional Lamination Process

For a considerable period of time, dry lamination was the mainstream in the industry. However, on the scale of sustainable development, the drawbacks of the traditional path have been infinitely magnified in the application of shrink sleeve packaging:

- Emission red line: Traditional processes rely on a large amount of solvents to dilute adhesives, and the cost of treating VOCs generated during production is extremely high. Under the backdrop of carbon neutrality, this is not only an economic burden but also a compliance red line.

- Energy consumption trap: To volatilize the solvent, the production line must be equipped with drying tunnels dozens of meters long for high-temperature heating, consuming a large amount of electricity or natural gas. This high-carbon-emission manufacturing method runs counter to sustainability.

- Residue risk: If there is a trace amount of solvent residue during the drying process, it is very likely to produce an unpleasant odor under the fully wrapped structure of the sleeve label, and even migrate into the interior of the food, affecting the brand reputation.

Why Sustainable Shrink Sleeve Packaging Depends On Solventless Lamination?

When sustainability is taken as the ultimate indicator, solvent-free lamination is no longer merely a better option, but has become a realistic reliance for label manufacturing. This dependence is reflected in the following three core logics:

1. Zero emissions in the manufacturing process

Solvent-free processes eliminate the use of organic solvents from the source. For manufacturing enterprises, this means there is no need to invest in expensive exhaust gas treatment facilities, nor is there the pressure of complex VOCs emission indicators. This green manufacturing attribute has already set a green tone for the shrink sleeve packaging before they enter the market.

2. Safety

Since the process itself does not involve solvents, solvent-free lamination fundamentally eliminates the possibility of solvent residue. In the packaging form of shrink sleeve packaging that covers all areas and have extensive contact, this natural safety greatly simplifies the compliance difficulty of food-grade and daily chemical-grade packaging. It provides brand owners with a more transparent and traceable security boundary.

3. Energy conservation and carbon reduction

Sustainability must stand the test of energy consumption. Solvent-free lamination eliminates the need for a large drying system, and its equipment takes up less space and significantly reduces operating power consumption. Compared with traditional dry lamination, the comprehensive energy consumption of solvent-free processes is usually only a fraction of that of the former. This improvement in efficiency is the key for shrink sleeve packaging to achieve full life cycle low-carbonization.

Sinstar Thoughts

We have observed that the industry’s shift towards solvent-free lamination is not merely due to the preference of brand owners, but rather an inevitable outcome derived from technology.

With the popularization of green trade barriers and the carbon footprint declaration system, flexible packaging suppliers will find that if they continue to use traditional processes, the shrink sleeve packaging will lose their competitiveness in carbon accounting. Therefore, Sinstar is transforming solvent-free lamination technology into an entry requirement in the shrink sleeve packaging field. This is no longer a discussion about “whether we should be more environmentally friendly or not”, but rather that sustainability cannot be achieved without choosing solvent-free options.

In conclusion, the realization of sustainable shrink labeling does not lie in “what kind of film is used”, but in “what technical approach is adopted to combine these films together”.Discussing the sustainability of labeling without solvent-free lamination would overlook the environmental costs in the manufacturing process. For packaging enterprises pursuing long-term development, adopting Sinstar’s solvent-free manufacturing solution is an inevitable path to achieving sustainable packaging.