How Anti-Counterfeiting Packaging Protects Your Brands and Consumers?

In the context of an increasingly complex global supply chain, counterfeit products have no longer been a problem confined to a few industries. Domains such as cosmetics, food and beverages, medicine, and clothing accessories have all been affected to varying degrees by fake goods.

Meanwhile, in a market with a wide variety of products, packaging is no longer merely a protective shell for the product. For brands, packaging serves as the identification mark of the product; for consumers, it is an important criterion for determining authenticity. However, as counterfeiting techniques continue to improve, traditional packaging is no longer sufficient to solely fulfill the responsibility of anti-counterfeiting.

In this context, the Lamination as a crucial step in packaging manufacturing is increasingly becoming an important part of the anti-counterfeiting system.

What Is Anti-Counterfeiting Packaging?

Anti-Counterfeiting Packaging is not merely about attaching a label or adding a QR code to the packaging. Instead, it is a comprehensive design that combines structure, materials, processes and digital technology to enable the product to possess the following three capabilities:

- Can be identified: Consumers can determine whether the product is genuine.

- Can be protected: The product is not easily tampered with during the distribution process.

- Can be tracked: The brand can monitor the whereabouts and status of the product.

Compared with ordinary packaging, the core of anti-counterfeiting packaging is not appearing attractive, but being useful. Its goal is not to draw attention, but to build trust.

In the cosmetics industry, packaging not only needs to be counterfeit-proof but also should reflect the texture and high-end feel. Therefore, counterfeiting prevention is often carried out simultaneously with the design of the appearance and the material used for touch.

In the food and beverage sector, safety and traceability are more important. The anti-opening structure and information tracking are the key points.

In the pharmaceutical industry, regulatory compliance is the core. Serialization and traceability systems are almost standard.

In the clothing and accessories industry, counterfeiting is often combined with tags, packaging, and digital verification to protect the brand’s premium value.

How Counterfeits Harm Brands and Consumers?

For the brand itself, counterfeit products will directly erode its market share. What’s more serious is that they will damage the brand image that has been built over many years. Once consumers have a negative experience due to purchasing counterfeit goods, the responsibility usually falls on the brand rather than the counterfeiters.

In the fields of food, cosmetics, and medicine, for consumers, counterfeit products represent potential health risks. Even in the clothing and accessories industry, counterfeit goods bring uncertainties in terms of quality, experience, and after-sales service.

From this perspective, anti-counterfeiting packaging is not an unnecessary expense, but rather a way of managing risks.

Common Technical Methods For Anti-Counterfeiting Packaging

When a consumer picks up a product from the shelf, their judgment is often based on intuition. The perfect edge coverage, the smooth and bubble-free surface of the packaging, as well as the changing-shaded anti-counterfeiting logo that glows with different angles – all these details are subtly conveying a message to the consumer: “This is a genuine product.”

In addition, the lamination also plays a crucial role in protecting the digital anti-counterfeiting information. Modern coating machines can achieve a variety of complex anti-counterfeiting functions. Nowadays, many packages are printed with “one item, one code” traceability QR codes. High-quality coating can ensure that these QR codes are not damaged or stained during transportation and storage, ensuring that consumers can have a smooth experience when scanning and verifying.

Holographic Film

This is currently the most widely used form of visible anti-counterfeiting technology. By using a laminating machine to combine a film with laser-generated holographic patterns with the packaging paper, the product will display a dazzling visual effect under different light conditions. This effect is extremely difficult to replicate through ordinary scanning or printing.

Touch and texture anti-counterfeiting

Through special coating technology, the surface of the packaging can be made to have a velvet-like feel, a frosted look, or specific raised and recessed textures. This unique physical touch not only enhances the quality of the product but also provides consumers with an intuitive way to identify it.

Anti-tampering structure

Certain high-performance laminated materials have the characteristic of immediately deteriorating upon tearing. Once the packaging is opened, the laminated layer will leave an irreversible mark (such as the word “VOID”), effectively preventing the product from being tampered with during the distribution process.

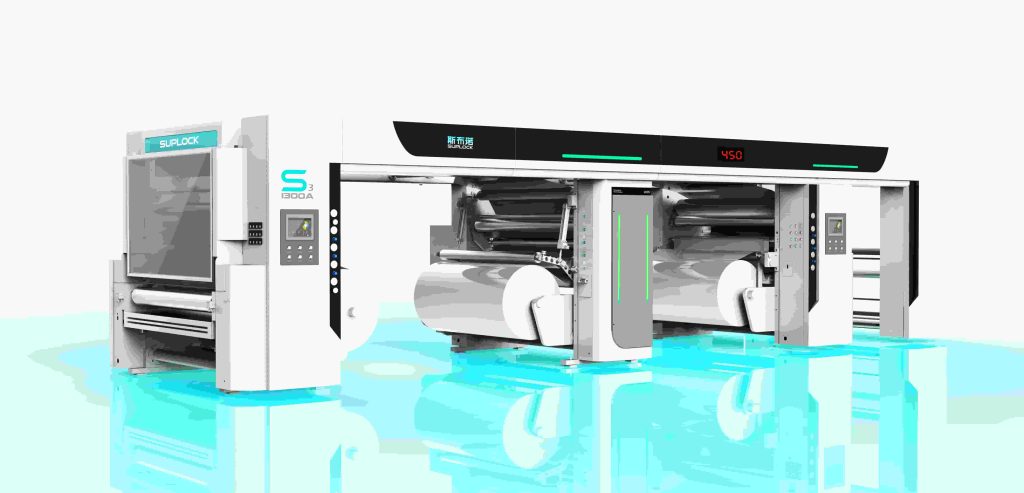

Why Choose A High-Performance Lamination Equipment Is The Foundation Of Anti-Counterfeiting?

The realization of anti-counterfeiting technology cannot be achieved without high-precision mechanical equipment. If there are wrinkles, uneven tension, or inaccurate temperature control during the coating process, even the most expensive anti-counterfeiting film materials will fail to achieve the expected effect, and may even result in a significant waste of materials.

For packaging manufacturers, choosing a reliable laminating machine is of utmost importance:

- Precise tension control: Ensure that the holographic anti-counterfeiting patterns do not deform due to stretching during the compounding process.

- Stable temperature control system: Ensures that the anti-counterfeiting film is firmly bonded to the substrate, without peeling or blistering, maintaining long-lasting anti-counterfeiting effectiveness.

- Multifunctional integration: Modern equipment can be compatible with various membrane materials, helping brand owners continuously upgrade their anti-counterfeiting solutions.

Anti-counterfeiting packaging is not a one-time project but rather a constantly evolving system. In this system, laminating technology, with its intuitive visual effect and reliable physical properties, always holds a central position. By introducing advanced coating technology, the brand is not only safeguarding its own profits, but also fulfilling its commitment to consumer safety. In this era where trust is more valuable than gold, a reliable anti-counterfeiting packaging that can withstand tests is undoubtedly a solid foundation for the brand’s long-term success.