From PET to Aluminum Foil: Solventless Lamination in Multi-Format Packaging Lines

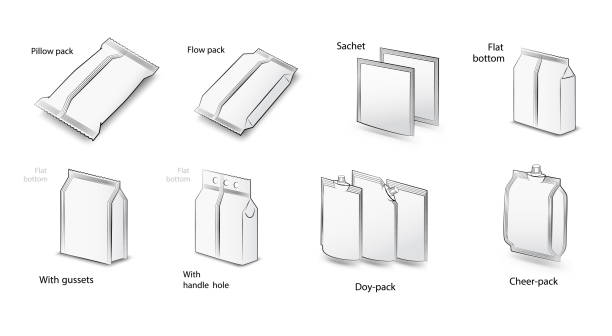

In modern packaging production workshops, we often witness such a scene: the production line is running at high speed, processing a batch of PET/PE material bags for daily chemical products. However, as the next order approaches, the operator must quickly adjust the equipment to prepare for food packaging made of aluminum foil.

This Multi-format production mode has become the norm in the industry. To meet the market’s demand for SKUs, packaging enterprises have to confront extremely complex substrate switching. However, while many enterprises focus on how to quickly change molds for downstream packaging machines, they often overlook a decisive previous process – solventless lamination.

If there is a problem with the material compatibility in the composite process, then no matter how advanced the downstream packaging machine is, it may face frequent downtime or leakage risks.

When Switching Across–Materials, What Are We Worried About ?

When the production line switches between different material structures, such as PET, PE, aluminum foil or paper, the significant differences in physical properties can pose challenges to the process.

Tension control

The most direct issue lies in the tension balance. PET has good rigidity, while PE is highly stretchable. If the control accuracy during lamination is insufficient, internal stress will occur in the film after winding. These stresses will suddenly release when entering the downstream multi-format packaging line, causing the bags to curl, form crooked, and even develop tiny wrinkles at the heat-sealing area. These minor defects are precisely the chief culprits that lead to the failure of the Leak Testing of the finished products.

Differences in glue compatibility

The requirements for the amount of glue and curing speed vary among different material combinations. For instance, to ensure barrier performance, aluminum foil composite structures usually require a relatively high coating amount. Transparent films or light films, on the other hand, pay more attention to visual effects and uniformity. If the coating control is not precise, it may not only cause poor bonding but also lead to glue overflow or tunnel phenomenon, affecting the quality of the roll material.

Friction coefficient and surface condition changes

Solventless adhesives will migrate during the curing process, affecting the coefficient of friction (COF) on the film surface. When the COF fluctuates too much, the downstream packaging machine may experience jamming or film slippage abnormalities during the film pulling process, thereby affecting production efficiency and the stability of the finished product.

So, how can we handle both thin and stretchable films and heavy and easily damaged aluminum foil on the same device?

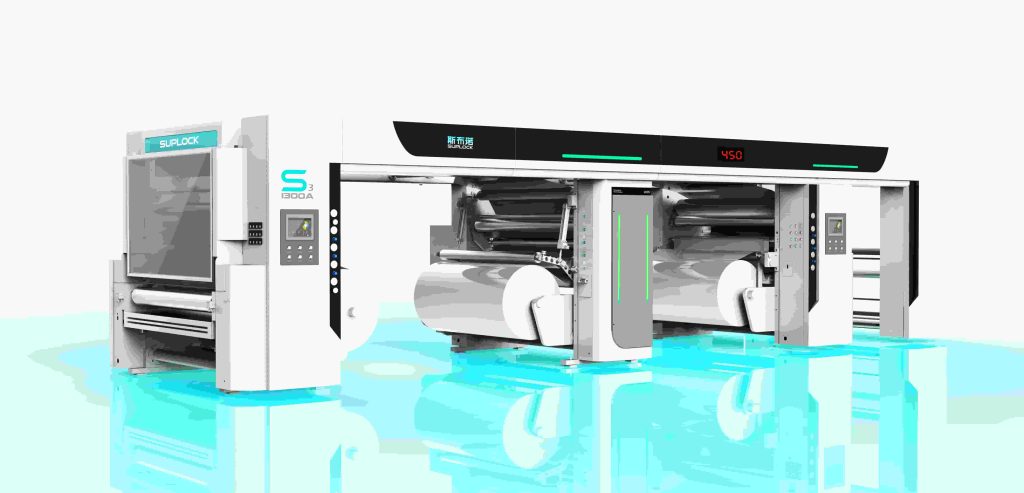

How Does a Solventless Laminating Machine Achieve High-Precision Material Matching?

In multi-format production, solventless laminating machines are key equipment for achieving efficient substrate adaptation. Through precise control and digital management, the smooth compounding of different materials can be guaranteed.

High-precision tension closed-loop system

Modern solventless laminating equipment usually adopts full servo drive. The core significance lies in that when the equipment senses the base material switching from rigid PET to flexible PE, the system can automatically fine-tune the tension difference between each stage of the rollers. This constant tension control ensures that the composite film has excellent flatness when entering the downstream packaging machine, laying the foundation for the automated format change operation.

Digital fine-tuning of coating amount

Different material combinations have completely different requirements for the amount of glue used. For instance, to ensure barrier properties, aluminum foil structures usually require a slightly higher coating amount, while transparent film structures pursue visual purity. Through digital coating control, operators can quickly retrieve preset parameters for orders of different formats, ensuring that each layer of glue is “just right”, adhering firmly while avoiding the negative impact of excessive glue on the performance of the film.

Surface condition monitoring

Introducing visual inspection or online monitoring systems during the lamination process can detect defects such as bubbles, impurities or uneven coating in real time. This type of pre-quality control can effectively reduce the risk of substandard coils entering downstream processes, thereby lowering the scrap rate and rework costs.

What If We Transformed Your Production Lines?

Today, with multi-format production becoming the norm, the real challenge is no longer merely whether it can be done, but whether it can be done stably and continuously. When solventless lamination processes have sufficient material compatibility, the performance of the production line will no longer rely on frequent trial runs or personal experience, but will be based on predictable and replicable processes.

This means that material switching is no longer necessarily accompanied by downtime and loss; The format adjustment of downstream packaging machines no longer needs to repeatedly give way to the unstable state of the rolls at the front end. The compound process has transformed from “passively adapting to order changes” to actively providing stable input for the entire production line, becoming a key support point in multi-format production.

For packaging enterprises, this change is not merely an improvement in the performance of a single piece of equipment, but rather an upgrade in production methods – bringing complex multi-specification demands back into a controllable process.

Solventless Lamination Solutions for Multi-Format Packaging by Sinstar

The flexibility of multi-format packaging should not come at the expense of production efficiency and packaging quality. solventless lamination process, as a key link in the manufacturing of flexible packaging, has long transcended the simple meaning of environmental protection.

Through precise mechanical control and scientific parameter management, solventless laminating machines can provide high-quality and highly adaptable substrate support for the complex and ever-changing packaging demands of downstream industries. Only when the front-end composite process is fully optimized can the back-end packaging line operate stably during multi-specification switching and achieve truly efficient production.

If you are seeking more reliable solutions for frequent substrate switching, stability fluctuations or downstream sealing issues, professional solventless lamination process optimization might just be a key step to enhance overall production performance. Welcome to communicate with our technical team to discuss the process configuration and equipment solutions that are more suitable for your current production structure.