Sustainable Packaging with Multi-Layer and Solventless Lamination Technology

Changes are occurring in the flexible packaging industry, increasingly focusing on the need for flexible packaging and providing more sustainable options for customers. Investments are being made in new sustainable technologies such as solventless and multi-layered laminating technologies. These technologies are key to resolving the packaging dilemma regarding whether to prioritize packaging that meets industry performance standards or packaging that is sustainable. In the past, packaging options had sufficient recyclability to be considered sustainable. New opportunities in packaging and laminating are dedicated to sustainability in packaging. Other emerging advanced technologies in packaging and laminating will incorporate sustainable practices and will fundamentally transform the flexible packaging industry. This represents sustainable high-performing flexible packaging.

The Role of Eco-Friendly Adhesives

Manufacturers have used traditional solvent-based adhesives, multi-layer lamination, and created traceable eco-pollution in the environment for quite a long time. Various alternatives are eco-adhesives, eco-friendly, and water-based or bio-adhesives used in the industry due to their high bond strength and no harmful emissions.

Eco-adhesive use in multi-layer laminating machines allow packagers to produce high barrier, durable, and compliant packaging to global eco demands of the FDA and EU.

For the packaging of food, drugs, and electronics, the eco-adhesive not only allows packagers to achieve their sustainability goals, but it is also a high quality and reliable laminated packaging.

Solventless & Water-Based Lamination Technologies

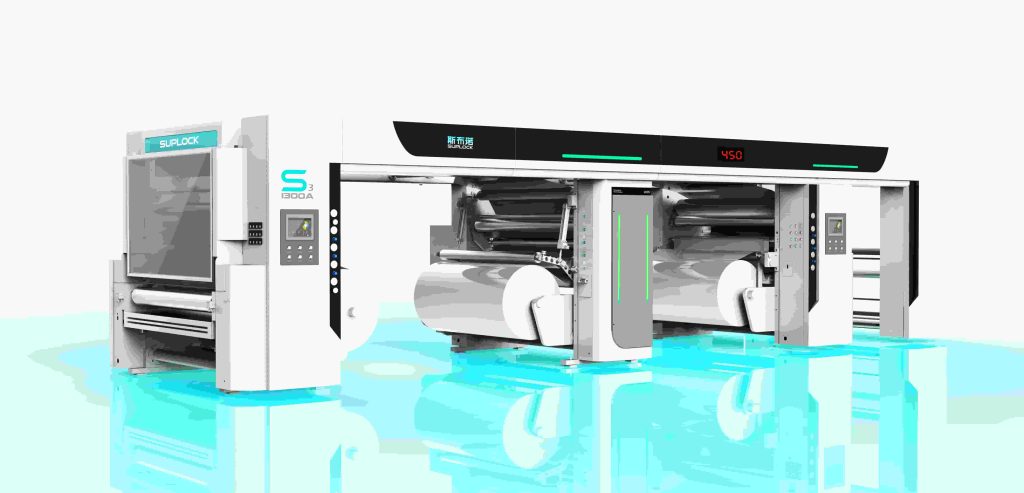

Solventless laminating machines are a great way to improve how we do packaging. These machines are far more energy efficient than traditional laminating machines. This type of laminating uses less energy to cure. This also means that it is better for the environment, as it produces fewer VOC emissions. If this progress is to be continued, laminating machines that are used in flexo printing will be better for our planet.

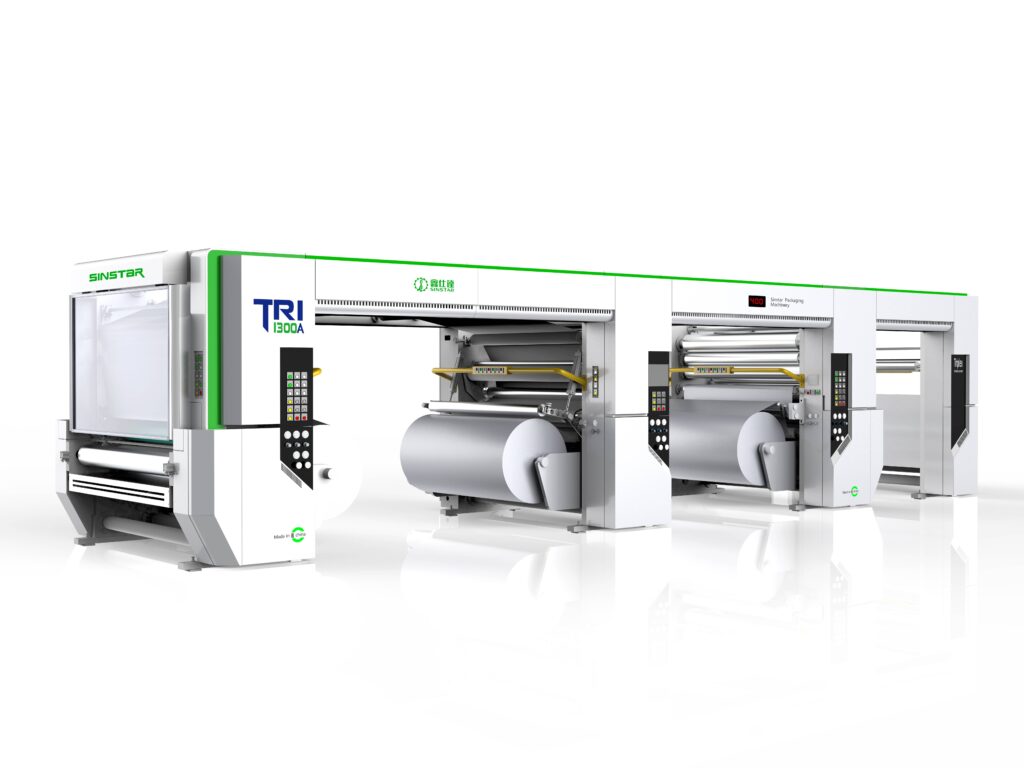

Another type of sustainable laminating is water-based lamination. This type of laminating is also used in packaging. This water-based lamination is also used in triplex lamination machines. This means that the machines in the packaging industry do not have to break environmental regulations.

These processes use fewer materials, ensuring fewer materials need to be bought, and that there will be a better working environment. Manufacturers are able to be more sustainable by cutting the materials they need to use and being able to laminate more flexibly.

High-Barrier Recyclable Films

Protecting items from moisture, oxygen, and other contaminants while also elongating their shelf-life is essential, and that’s what high-barrier films do best. Sustainability has given high-barrier recyclable multi-layer films traction. Barrier performance coupled with recyclability is what gives PET/EVOH/PE laminates and metalised layers their versatility.

Multi-layer laminating machines are designed to process these films and maintain consistent quality throughout the lamination process without compromising the functionality of the films. The combination of these high barrier films and bio-based adhesives enables the packaging to be both highly efficient and environmentally friendly.

Recyclable high barrier films not only protect the products but also the earth by aligning with those in power on their sustainability journeys, thereby allowing the films to be used in packaging for durable, environmentally responsible products such as food, pharmaceuticals, and electronics.

Energy Efficiency & Carbon Footprint Monitoring

The energy costs incurred during the lamination stages do vary considerably. There is currently a trend in the industry, especially in the new generation of triplex and multi-layer laminators, with energy-efficient laminating designs. Devices with controlled heating and cooling of the laminating devices and automated control of the flow of glue, as well as roller adjustments regarding pressure and the flow of adhesive, permit a reduction in energy expenditures during laminations.

In addition, the industry is starting to use embedded carbon footprint monitoring systems. Such systems of integrated carbon footprint monitoring track energy consumption, report on the levels of CO2 emissions, and provide energy feedback that reflects on the systems and the changes in energy automation in real-time.

The adoption of energy-efficient machines with integrated carbon monitoring technology will allow clients in the printing industry not only to implement cost-efficient operational activities but also to deliver tangible results in compliance with comprehensive sustainability strategies. This value is crucial for many brands striving for complete business systems to achieve mandatory certification.

Integrating Sustainable Practices in Production

To design 100% sustainable packaging, a multifaceted model must be designed. Businesses can utilise:

- VoC Free, Eco-Friendly Adhesives: Bonds layers without using any VoC emitting adhesives.

- Lamination Technologies: Use of “solventless” or “water-based” for a low-impact, energy efficient, and sustainable processing.

- Barrier. High-Recyclable Films: Maintain product integrity and achieve more circular economy objectives.

- Energy and Carbon Tracking: Monitors and streams processes to GHG reduction goals engagements.

Processing frameworks of sustainable packaging integrated analytics have overall value in these practices to ESCs. Leading companies in packaging get a balance of operational efficiencies and durational savings.

Challenges & Solutions

Lamination isn’t perfect. Even with these benefits, there are some challenges with sustainable lamination:

- Material compatibility: Recyclable films need certain temperatures. If that isn’t accurate, there are problems with delamination.

- Technical Complexity: Structures that have more than two layers need more sophisticated machine adjustments.

- Investment Policy: New eco-friendly lamination equipment typically has a higher upfront cost.

Here are a few suggested solutions:

- Lamination machines with more than two layers that have programmable adjustments.

- Research to work on films and adhesives that are compatible.

- Optimising processes to lessen waste, achieving more efficiency and higher yield.

Conclusion

Advanced sustainable multi-layer lamination technologies demonstrate how companies can achieve high-performance and low-impact packaging simultaneously. With the implementation of bio-based adhesives, solventless/water-based lamination processes, and the incorporation of high-barrier recyclable films in combination with energy/carbon management, laminators can produce packaging solutions that maintain product protection, sustain a small environmental footprint, and fulfil regulatory and consumer conscientious challenges.

With the implementation of multi-layer laminate technologies, companies can achieve the optimal balance between performance, sustainability, and operational efficiencies and actively contribute to a greener and more responsible packaging industry.