What Is Soft Touch Lamination and Why It So Popular in Premium Packaging?

At first glance, many premium packages appear similar. They use muted colors, matte finishes, and minimal design. Yet once you pick them up, the difference becomes immediately clear. Some packages simply look refined, while others feel refined. That subtle tactile distinction is often the result of soft touch lamination.

Over the past few years, soft touch lamination has become a preferred choice in high-end packaging. But what exactly makes it different, and why has it gained such strong popularity?

Why Do Some Matte Packages Feel Different?

Matte packaging is no longer uncommon. However, not all matte finishes deliver the same sensory experience. Some surfaces feel flat or slightly rough, while others feel smooth, velvety, and warm to the touch.

This difference is not accidental. It comes down to the lamination method used on the surface. Soft touch lamination is specifically designed to enhance tactile perception, turning packaging from something that is only seen into something that is also felt.

What Is Soft Touch Lamination?

Soft touch lamination is a surface finishing process that applies a specialized laminating film to printed materials. Unlike standard matte lamination, which mainly reduces gloss, soft touch lamination focuses on both appearance and touch.

The result is a surface that feels smooth and almost rubber-like, while maintaining a soft, low-reflection visual effect. In addition to its distinctive feel, soft touch lamination is known for reducing visible fingerprints and smudges, helping packaging maintain a clean and premium look even after repeated handling.

Rather than emphasizing technical specifications, soft touch lamination is best understood through its purpose: improving the overall sensory experience of a product.

Soft Touch Laminate vs. Standard Matte Lamination

While soft touch lamination and matte lamination may look similar from a distance, their performance differs in several important ways.

Standard matte lamination focuses mainly on visual results, providing a non-glossy finish that reduces glare. Soft touch laminate, on the other hand, adds a tactile layer that enhances how the surface feels in the hand.

Soft touch finishes generally offer:

- A smoother, more refined texture

- Better resistance to fingerprints

- A more distinctive premium impression

These differences may appear subtle, but they are often noticeable to end users, especially in competitive markets where packaging plays a key role in brand perception. This distinction becomes even more important when brands are looking for ways to stand out without changing their core design.

Why Premium Packaging Prefers Soft Touch Lamination

In premium packaging, first impressions matter, but lasting impressions matter even more. Soft touch lamination supports this goal in several ways.

Enhanced brand perception

The soft, elegant feel naturally aligns with high-quality products and premium positioning.

Tactile memory

Touch creates a stronger sensory connection than sight alone. A pleasant surface feel can leave a lasting impression long after the initial interaction.

Visual differentiation

Soft touch lamination delivers a refined matte appearance that feels intentional rather than ordinary, helping products stand apart on crowded shelves.

For brands focused on quality, detail, and experience, soft touch lamination becomes more than a finish—it becomes part of the brand message.

Common Applications of Soft Touch Lamination

Soft touch lamination is widely used across different industries, particularly where presentation and user experience matter.

- Packaging: luxury goods, cosmetics, electronics, and specialty food products

- Book covers: both hardcover and premium paperback publications

- Brochures and catalogs: corporate presentations and brand materials

- Gift boxes and presentation boxes: products where unboxing experience is important

In each case, the goal is the same: elevate perceived value without overwhelming the design.

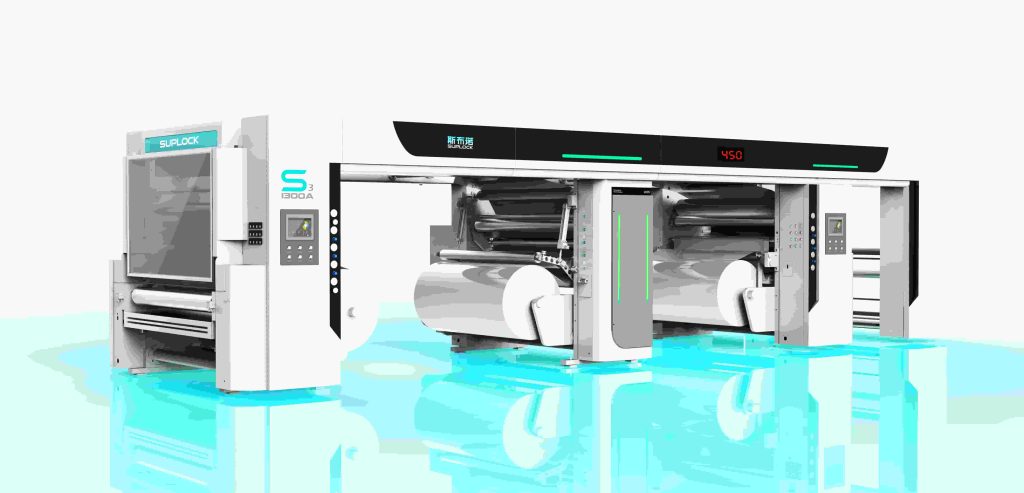

How Is Soft Touch Lamination Produced?

At a basic level, soft touch lamination is achieved by bonding a specially coated film to printed substrates using laminating equipment. The process itself is similar to other lamination methods, but the materials and surface properties of the film are what create the distinctive effect.

Depending on production requirements, soft touch lamination can be integrated into different lamination systems and workflows. This flexibility makes it suitable for both traditional and more advanced, environmentally conscious production setups, a topic worth exploring in more detail separately.

Is Soft Touch Lamination Right for Your Product?

Soft touch lamination is not always the default choice, nor does it need to be. Its value becomes most apparent when packaging is meant to communicate quality, attention to detail, and a premium experience.

If your product relies on differentiation, tactile engagement, or brand perception, soft touch lamination may be worth considering. Understanding its characteristics is the first step toward deciding whether it fits your design, budget, and production goals.

As packaging continues to evolve beyond simple protection, finishes like soft touch lamination highlight how surface details can make a meaningful difference.If you want to learn more about the solutions for soft packaging lamination, we offer comprehensive support ranging from materials to equipment, helping you achieve a high-quality packaging experience.