How Can Set-Up And Operation Procedures Be Optimized For Solventless Laminating Machines To Increase Efficiency?

In solvent-free lamination production, efficiency is often not determined by a single action, but rather a systematic project composed of equipment setup, personnel operation, quality control and the collaborative efforts of automation. Many enterprises encounter a common question when using solvent-free laminating machines – the equipment is fast enough, but the overall efficiency is hard to be truly brought into play. So, where exactly should one start? If the entire process is broken down, it will be found that there are many details that can be optimized. This article will guide you step by step to understand how to maximize the value of solvent-free laminating lines through scientific Settings and operations.

The Core Principle And Advantages Of Solventless Lamination

Solvent-free lamination uses two-component adhesives, which are precisely mixed by metering pumps and then achieve a strong bond between materials with an extremely low coating amount. Compared with traditional solvent-based processes, it does not require ovens, solvent residue treatment, or long waiting times for curing, thus having a faster production speed and lower energy consumption.

In addition, due to the low coating amount and less material waste, solvent-free laminating machines are also more suitable for factories that pursue long-term cost control. For high-end flexible packaging, food packaging and industries with high environmental protection requirements, it is not only a technological upgrade, but also a transformation in manufacturing methods.

A Key Component Of The Solventless Lamination System

A mature solvent-free lamination production line is usually composed of multiple key modules working together:

- A stable unwinding system ensures uniform tension when the base material enters the equipment

- The precise two-component metering and mixing system determines whether the adhesive is uniform or not.

- Coating unit, controlling the position of adhesive application, coating amount and coating stability

- The pressing roller group completes the bonding of two base materials

- The curing zone and the winding system ensure that the adhesive completes the initial bonding

- The temperature control and automation module ensures the stability of the entire process flow

Each module affects the final product quality, so optimization must be carried out from a systems perspective rather than focusing only on a certain part.

Phase One: Precise Setup For Optimal Performance

Substrate treatment and preparation

The state of the base material before the start of production often determines whether the production can proceed smoothly. Slight curling, dust, and uneven humidity can all affect the application of adhesive and the bonding effect. Therefore, before starting up, it is necessary to confirm:

- The edges on both sides of the base material are smooth without obvious deformation.

- The preset tension value matches the material properties.

- The surface cleanliness meets the standards, free of dust or oil.

Adequate preparatory work in advance can reduce the number of adjustments during the operation of the equipment, allowing efficiency to start improving from the first minute of startup.

Calibrate the adhesive application system

The coating amount is one of the most sensitive variables in solvent-free processes. Due to the low coating amount, any slight deviation may lead to a decline in the final lamination performance. Therefore, during the setup process, it should be ensured that:

- The ratio of components A/B is accurate and consistently stable.

- The temperature setting can keep the viscosity within an appropriate range.

- The glue mixing system operates smoothly without any pulsation.

- The coating points are uniform, without any glue jumping or deviation.

A precise gluing setting not only enhances the initial bonding effect but also reduces unnecessary material waste.

Optimize the lamination joint and curing zone

Pressing is the key link for the true combination of two layers of materials. Appropriate pressure, roller surface temperature and entry Angle can all affect the final appearance and strength. Meanwhile, the curing zone needs to maintain a reasonable tension to prevent the adhesive from being stretched or shifted before it is fully cured. Good bonding and curing Settings can significantly reduce problems such as bubbles, white fog, and misalignment, making the composite products more stable.

Phase Two: Excellent Operations And Process Control

Fine-tune the machine Settings to achieve optimal efficiency

Even if the standard Settings have been completed, minor differences may still occur in actual production, such as temperature changes, batch differences of base materials or speed changes. Therefore, the operators need to make adjustments according to the actual situation

- The matching of tension and velocity

- Fine-tuning of coating width and scraper gap

- The bonding pressure should be moderately adjusted according to the thickness of the base material

Although these minor adjustments are not obvious, they often effectively enhance quality stability and production efficiency.

Ensure that the adhesive is applied flawlessly during the operation process

During production, if there is slight glue jumping, uneven glue patterns or fluctuations in the coating amount, the machine should be stopped immediately for inspection, as these problems often indicate unstable glue mixing, proportion deviation or abnormal temperature. Timely handling can prevent the problem from escalating and also avoid a large amount of scrapping.

Advanced quality control and data monitoring

Nowadays, more and more solvent-free devices are equipped with real-time monitoring functions, such as:

- Online thickness measurement

- Real-time display of coating amount

- Pressure, tension and temperature curves

- Production data is automatically recorded

These data can not only help determine the status of the equipment, but also assist in creating historical parameter archives, providing a basis for future process optimization.

Phase Three: Troubleshooting And Advanced Optimization Of Solvent-free Laminating Machines

Solve common lamination defects

Common defects in composite products, such as bubbles, whitening of composites or poor delamination, are often related to the coating amount, bonding pressure or material condition. Understanding the principles behind these defects can reduce trial-and-error time and increase production.

Master the challenges of polymerization and curing

The curing of solvent-free adhesives relies on chemical reactions and is thus highly sensitive to temperature, humidity and proportion. Checking the condition of the adhesive in advance and observing environmental changes can make the curing more stable and also reduce the problem of peeling in the later stage.

The operators took the initiative to troubleshoot the faults

Excellent operators can often detect problems before they occur, such as identifying potential issues through changes in sound, uneven roller temperature, and tension fluctuations. The awareness of maintaining initiative is an important factor in stabilizing production efficiency.

Tips for Maximize Overall Efficiency And Sustainability

Improve the efficiency of model change

One of the advantages of solvent-free lamination is that the mold change is faster, but if the preparation in advance is not sufficient, a lot of time will still be wasted. Therefore, it is suggested that:

- Prepare all the materials and adhesives in advance

- Establish a process parameter file for immediate invocation

- Clarify the SOP for model change to ensure that every operator can carry it out quickly

This not only shortens the model change time but also reduces mistakes during the model change process.

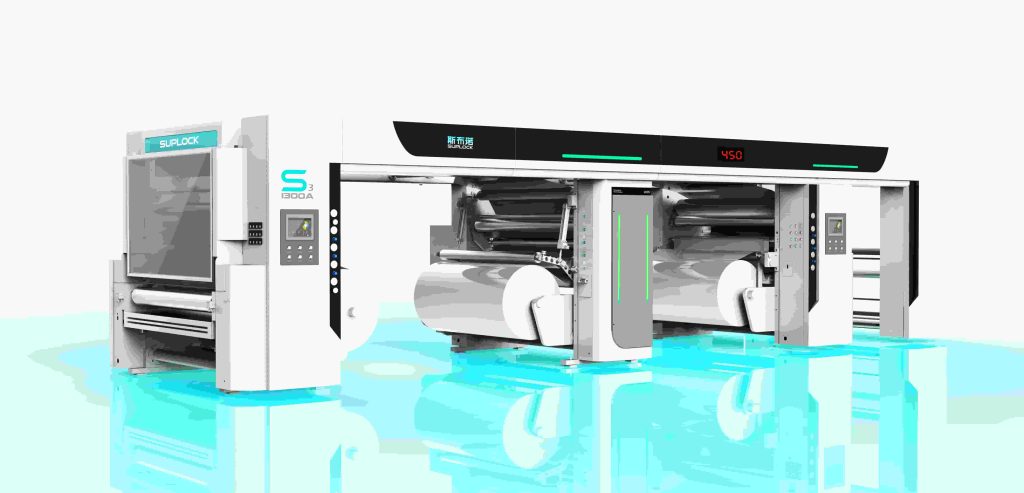

In addition to preparing process parameters, materials and adhesives in advance, using equipment with advanced roll changing design can also significantly reduce downtime. You can choose our SUPLOCK S2-1300A II dual-station solvent-free laminating machine, which can simultaneously achieve three-layer lamination and continuous material change, keeping the production process continuous and avoiding downtime due to material replacement. This type of design not only enhances the efficiency of model change but also enables the equipment to maintain stable operation for a long time under high production demands, significantly improving the overall production efficiency.

Minimize energy consumption to the greatest extent

Solvent-free composites already have natural energy-saving advantages, but they can still be further optimized in the following directions:

- Reduce unnecessary preheating time

- Use energy-saving motors and optimized temperature controllers

- Avoid prolonged idling to prevent wear and tear

In the long term, these small steps can significantly reduce the overall energy cost.

The integration of intelligent technology and automation

More and more factories are adopting automatic proportional control, intelligent tension systems, online quality monitoring and even AI analysis. By integrating these technologies, human errors can be reduced, allowing the equipment to operate in a more stable manner and further enhancing efficiency.

Conclusion

To achieve high efficiency, solvent-free laminating machines must be comprehensively enhanced in terms of equipment setup, operational details, quality control, and automated collaboration. Only when every step remains stable, precise and controllable can the production line truly leverage its speed advantage while maintaining high quality, low energy consumption and high consistency. Through systematic optimization, enterprises can achieve more significant improvements in terms of production capacity, cost and environmental performance.If you are looking for equipment suitable for upgrading your production line, Sinstar specializes in the research and development and manufacturing of solvent-free laminating machines. Our product range includes various specifications of models, meeting different needs from daily flexible packaging to high-end multi-layer lamination. Welcome to contact us for more solutions. We will provide you with more suitable solutions and technical support based on your production goals and material types.