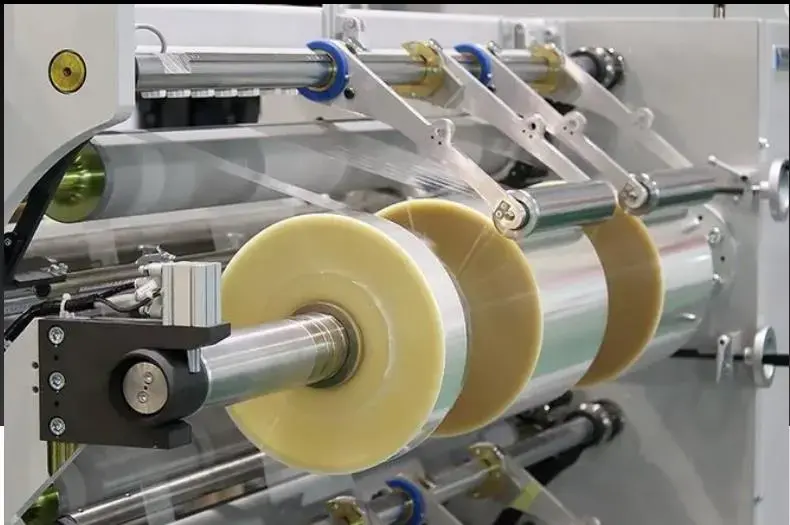

Tension Control Of Solventless Lamination Machine

During the entire solventless composite process, tension control is important, and precise tension control is the premise of ensuring the quality of the composite film.

Tension Control Methods Of Solventless Lamination Machine

The solventless lamination machine mainly has two tension control modes, one mode is a “floating roller” and the other mode is a “micro shift”.

The “floating roller” tension control has the advantages of large range control, adapting to the wide substrates, but the structure is more complicated.

The “micro displacement” type tension control has the advantages of high precision, high sensitivity, but since the detection range is small, the absorbance of the material roll fluctuation is small, so this method is generally only suitable for relatively thick or non-molar material.

In actual solventless composite production, a solventless machine may adopt different tension control methods in different sections.

Instruction For Tension Control Of Solventless Lamination Machine

1. During the solvent-free composite, the requirements for tension control are higher than that of ordinary compounds. The main reason is that there is no solvent composite initial adhesion, and the operational control is difficult, which may lead the quality problems. In addition, the solvent-free composite speed is much higher than the dry lamination machine. During the solvent-free composite, the tension after the thin film is slightly greater than the main arrangement, and the winding tension is greater than the rewinding tension. The winding taper is controlled within 20%. For different materials, each part of the tension control is different, and even the film of the same material produced by different manufacturers, its tension has to be slightly adjusted.

2. In the solventless composite, not only the accuracy of the tension control system, the matching of the tension between the two composite rolls is emphasized. Under the current technical conditions, many tension control systems have very high accuracy performance, which can meet the needs of solventless composite production. However, in the process of solventless composite operation, this is often encountered, which the matching of the two-layer materials is more difficult, which not only requires a good tension control system but also carefully understand the material features. More accurately, the tension of solvent-free composite requires that the elongation of the two-layer rolls is consistent by controlling the tension to ensure that the two-layer material does not occur the relative slip during the solventless composite.

3.The rewinding tension and pressure are the key to solventless composite tension control. Since the combination of the composite film and the overall condition of the material roll, are determined by the rewinding tension and pressure, adopting the segmentation independent tension and segment tension taper are the most ideal control mode.

It should be noted that the segment tension taper is mainly to compensate for the need for linear tension to the requirements of different material winding tension. Different tension tips can be effectively guaranteed to ensure the neatness of the winding while reducing the generation of core wrinkles.

Unwinding Device And Loading Pattern Of Solventless Lamination Machine

Unwinding device

The solventless laminator is mounted with an aluminum foil unwinding frame and an ordinary unwinding frame. In general, the path of the aluminum foil unwinding frame is shorter with a smooth guide roller, often adopting “micro displacement” tension control. The ordinary unwinding frame is long, often adopting the “floating roller” tension control.

When using an aluminum foil unwinding frame, only one frame is in a working condition during the composite process, that is, the ordinary unwinding frame is in a non-working state. Due to the simultaneous compounds of the two films, two unwinding frames are required to work at the same time.

Accordingly, there must be two tension control systems in the working condition.

Loading Pattern

There are two main methods of the solventless laminating machine and the reliability of the air shaft and shaftless pneumatic shaft are high.

The shaftless cone top type of loading pattern has the advantages of simple, fast, high efficiency, low operation intensity, but it has high requirements for the core tube and in order to ensure safety, this loading pattern has a higher requirement for equipment parts Also the manufacturing cost is relatively high.

In the current market, medium and high-speed solvent-free lamination machines with speed at 400 to 600 m / min, basically adopt air shaft loading patterns.

Summary

Tension control plays an important role for the whole solventless composite process and learning the tension control well can do a great favor for the work efficiency of solventless laminating machine.