Solventless Laminators in Pharmaceutical Packaging: Applications, Benefits & Trends

Decadently, the pharmaceutical packaging industry is experiencing a sea of change occasioned by stringent safety measures, growing sustainability outlooks, and the increased need for high performance flexible packaging. The solventless laminator is one of the most notable advances. Initially started for food packaging work, solventless lamination machines are finding growing acceptance in pharmaceutical applications where the need for sterility, low migration and process control is important.

This article aims to address why pharmaceutical packaging has contributed to the advancement of solventless lamination technology, appreciable traits propelling this change, and the current advancement of solventless laminators in reshaping medical and pharmaceutical flexible packaging.

Pharmaceutical Packaging: Performance and Safety Requirements

Pharmaceutical packages have to do more than just hold the product – they directly impact drug safety, efficacy, on-market life, and regulatory requirements.

1. High Barrier Performance for Drug Protection

Many pharmaceutical products are highly sensitive to moisture, oxygen, light, and temperature. Tablets, capsules, powders, and medical devices often require multi-layer high-barrier structures, such as PET/AL/PE, OPA/CPP, or aluminum-based laminates. These structures rely heavily on precise lamination to ensure long-term protection.

The consistent bonding strength of a pharmaceutical packaging laminator should be achieved without affecting the barrier status. One of the better features of solventless lamination in this regard is that it provides the feature of the uniform adhesive layers, which help in under high barrier and lighter packaging configurations.

2. Migration Control and Product Safety

Pharmaceutical flexible packaging has a major chemical migration as one of the most crucial issues. Traditional solvent-based lamination processes leave residual solvents that can transfer to drug products, thus constituting safety risks and regulatory issues.

Laminations without solvents completely remove organic solvents. Manufacturers relying on solventless laminating adhesive systems considerably lessen the chance of solvent residues contaminating their products, thus making solventless laminators very appealing for pharmaceutical and medical packaging.

The process of solventless lamination has completely done away with organic solvents. With the choice of solventless laminating adhesives, the manufacturers’ chances of residual solvent contamination are almost negligible, thus making solventless laminators very appealing for the pharmaceutical and medical packaging sectors.

3. Compatibility with Sterilization and Shelf Life Requirements

Pharmaceutical packaging often undergoes sterilization processes such as steam sterilization, ethylene oxide (EO), or gamma irradiation. Laminated structures must maintain adhesion, seal strength, and appearance after exposure to heat and radiation.

Modern solventless lamination machines are engineered to produce strong, chemically stable bonds that withstand sterilization processes and long storage periods without delamination or discoloration.

Why Solventless Laminators Are Gaining Popularity in Pharmaceutical Packaging

The move to solventless lamination is not a coincidence. It is a direct response to the operational, legal, and environmental problems that pharmaceutical packaging producers encounter.

1. Eliminating VOC Emissions and Solvent Residues

Pharmaceutical production facilities have strict regulations for volatile organic compounds (VOCs). The use of solvents in traditional lamination not only produces VOCs but also demands costly solvent recovery systems and large-scale ventilation.

On the other hand, VOC-free lamination done with solventless laminators makes it easier to meet environmental and occupational safety regulations. Thus, solventless lamination turns out to be highly appropriate for GMP-controlled pharmaceutical packaging facilities.

2. Cleaner Production and Safer Working Conditions

Solventless lamination eliminates the fire risks and toxic exposure that are related to the usage of solvents. For pharmaceutical packaging facilities that are cleanroom-like production environments, solventless technology not only makes the operation safer but also allows easier compatibility with hygiene-oriented workflows.

This cleaner process also aligns with pharmaceutical companies’ ESG and sustainability commitments, strengthening long-term supplier relationships.

3. Efficient Adhesive Use for Thin and Sensitive Films

Pharmaceutical packaging often uses thin films to reduce material usage while maintaining performance. Solventless laminating adhesives allow extremely precise coating weights, ensuring strong bonding even at low adhesive volumes.

Advanced high-precision solventless laminators enable uniform adhesive distribution across thin medical films, improving yield and minimizing material waste.

Key Pharmaceutical Packaging Applications for Solventless Lamination

The versatility of solventless lamination makes it suitable for a wide range of pharmaceutical and medical packaging formats.

1. Oral Solid Dosage Packaging

Blister lidding films, sachets, and strip packaging for tablets and capsules require excellent moisture barriers and consistent seal performance. Solventless lamination supports these requirements while minimizing migration risks.

2. Medical Device and Sterile Packaging

Medical devices often require sterile barrier systems with high peel strength and durability. Medical device packaging lamination using solventless technology provides strong, uniform bonding suitable for sterilization without compromising package integrity.

3. Unit-Dose and Sachet Packaging

Single-dose pharmaceutical sachets and pouches demand reliable sealing and precise lamination to ensure dosing accuracy and product stability. Solventless lamination equipment offers the consistency needed for high-volume pharmaceutical sachet production.

Technical Requirements of Solventless Laminators for Pharmaceutical Use

Not all solventless laminators are suitable for pharmaceutical packaging. Equipment must meet higher technical standards than those used in general consumer packaging.

1. Precision Coating and Uniform Adhesive Distribution

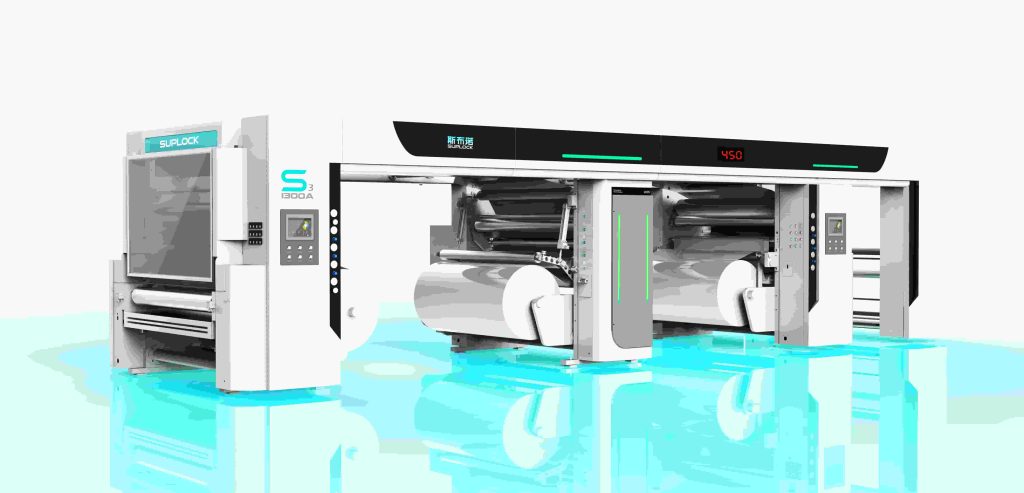

Pharmaceutical packaging requires extremely consistent adhesive application. Multi-roller coating systems, such as three-roller or five-roller designs, allow fine control over coating thickness and uniformity.

A high-precision solventless laminator minimizes defects such as bubbles, streaks, or uneven bonding that could compromise packaging performance.

2. Advanced Process Control and Quality Consistency

Pharmaceutical packaging manufacturers prioritize repeatability and traceability. Modern solventless laminators integrate precise tension control, synchronized drive systems, and digital process monitoring to ensure consistent lamination quality across production batches.

Stable lamination quality directly reduces scrap rates and improves compliance with pharmaceutical quality systems.

3. Compatibility with Pharmaceutical-Grade Materials

Solventless lamination machines must handle aluminum foil, pharmaceutical-grade PE, CPP, OPA, and specialty barrier films without damaging sensitive surfaces. Equipment flexibility is essential to support diverse pharmaceutical packaging structures.

Regulatory and Compliance Considerations

Pharmaceutical packaging is subject to strict regulations related to material safety, migration limits, and production hygiene. Solventless lamination supports compliance by reducing potential contamination sources and simplifying validation processes.

From a regulatory perspective, solventless lamination aligns well with GMP principles by offering controlled, repeatable, and clean production conditions. This makes it easier for packaging suppliers to meet the expectations of pharmaceutical brand owners and regulatory authorities.

Market Outlook: Strong Growth Potential in Pharmaceutical Packaging

The global pharmaceutical packaging market continues to expand, driven by aging populations, increased healthcare access, and growing demand for unit-dose and sterile packaging. At the same time, sustainability and safety concerns are reshaping packaging technology choices.

As a result, the solventless laminator market is expected to see sustained growth within pharmaceutical applications. Packaging converters that invest in solventless lamination technology position themselves to meet future regulatory demands, attract multinational pharmaceutical clients, and reduce long-term operating costs.

FAQ

Q1: Is solventless lamination suitable for pharmaceutical packaging?

Yes. Solventless lamination offers low migration risk, high barrier performance, and clean production conditions, making it ideal for pharmaceutical applications.

Q2: What materials can be laminated using solventless laminators?

Common materials include PET, OPA, aluminum foil, PE, CPP, and other pharmaceutical-grade films.

Q3: How does solventless lamination improve packaging safety?

By eliminating solvents, it reduces VOC emissions and minimizes the risk of chemical migration into pharmaceutical products.