How Solvent Free Adhesive and Zero-Aging Technology Are Transforming Modern Packaging

In the last few decades, the packaging sector transitioned towards sustainability, food safety, and carbon mitigation. Abandoning the harmful substances in adhesive systems and applying the solventless laminating machines have been significantly helpful in reducing VOC emissions.

However, the experience of many converters and many similar products shows that “solvent-free” does not always mean “fast” and “safe.” Solventless lamination, which still implies a waiting period–typically 48-72 hours, tends to bottleneck production and create new burdens on how one must meet the compliance guidelines for food safety.

A new generation of zero-aging (or almost zero-aging) technology is changing what solventless lamination can do. This article clearly and simply discusses the science, benefits, and real-world effects of this change.

The Hidden Bottleneck in Sustainable Packaging

Solventless lamination might seem the perfect resolution at first sight: no emissions of solvents, reduced environmental consequences, and the ability to act in line with the ever-tightening legislation. But many packaging plants in the industry are counting on aging chambers, where laminated rolls must take days to settle before being slit and shipped.

This waiting period is often a need in most of the traditional chemical-free adhesives since most of them cure in stages. Rushing the process by the converters to meet delivery deadlines may cause incomplete resin curing of the adhesive layer. This may result in bond failure, bad smell, or worse, a food safety hazard.

This creates a long-standing dilemma for the industry:

- Faster delivery is demanded by e-commerce, seasonal promotions, and fast-moving consumer goods.

- Long curing times are required to ensure safe and stable packaging performance.

Zero-aging technology directly addresses this contradiction.

What Is Solvent Free Adhesive?

To understand zero-aging, it helps to first answer a common question: what is solvent free adhesive?

Solvent-free adhesive refers to an adhering product that does not have organic solvents. Instead of relying on the evaporation of solvents for bond formation, it depends on chemical reactions, which most often take place between two components to provide them with a solid adhesive layer.

Key characteristics include:

- 100% solid content, meaning no solvent evaporation

- Very low VOC emissions, supporting environmental compliance

- High bonding strength, suitable for multilayer flexible packaging

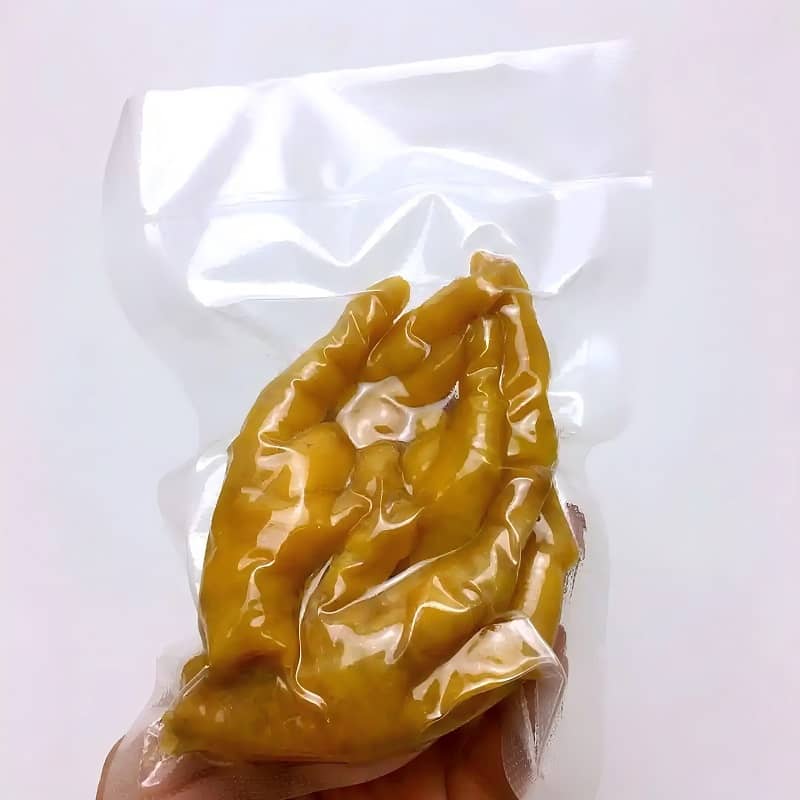

Solvent free adhesives are widely used for food, pharmaceutical, and personal care packaging. However, their curing speed depends heavily on chemical formulation, temperature, and time.

Why Curing Time Matters for Food Safety

In traditional solventless lamination, curing is not just about strength—it is also about safety.

Many polyurethane-based solvent free adhesives use reactive components that must fully react before the package is considered food-safe. If this process is incomplete, trace substances such as primary aromatic amines (PAA) may migrate into food products.

Under normal conditions, curing takes place gradually over 2–3 days. During this time:

- Chemical reactions slowly reach completion

- Migration levels decrease to within regulatory limits

- Bond strength stabilizes

When converters shorten this period without proper technology, they may unintentionally increase compliance risks.

Zero-Aging Technology: How It Changes the Chemistry

Zero-aging technology represents a fundamental change in how curing occurs.

Instead of relying on slow, time-dependent reactions, new-generation solvent free adhesive systems are designed to react almost instantly. This is achieved through:

- Ultra-fast dual-component reactions

- Highly optimized molecular structures

- In some cases, energy-triggered curing mechanisms

The result is that key chemical reactions reach completion during or shortly after lamination, rather than days later.

From a food safety perspective, this means:

- Migration levels rapidly fall below regulatory thresholds

- The risk of PAA formation is dramatically reduced

- Compliance is achieved without extended waiting periods

This makes zero-aging not just faster, but also more reliable.

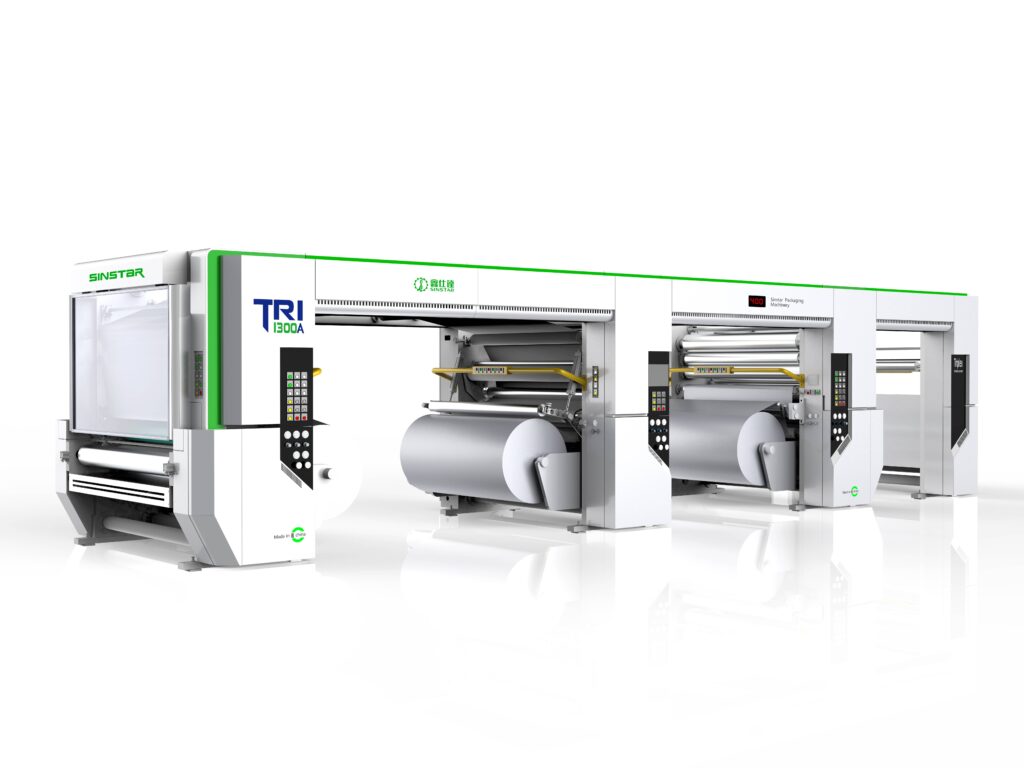

The Role of the Solventless Laminating Machine

Advanced chemistry alone is not enough. Zero-aging performance depends heavily on the capabilities of the solventless laminating machine.

Modern machines designed for zero-aging applications offer:

- High-precision coating control to ensure uniform adhesive layers

- Accurate mixing and dosing systems for two-component adhesives

- Stable web handling to support immediate downstream processing

Together, these features allow laminated material to be slit, inspected, or even shipped within hours of production.

In practical terms, the laminating machine becomes an active part of the curing process rather than a passive coating platform.

The End of Aging Rooms: Energy and Space Savings

One of the most overlooked benefits of zero-aging technology is its impact on factory energy use and layout.

Traditional aging rooms typically operate at 40–50°C, running continuously to maintain consistent curing conditions. This leads to:

- High electricity consumption

- Significant operational costs

- Large areas of factory space dedicated to work-in-progress storage

By eliminating or drastically reducing curing time, zero-aging systems allow converters to:

- Shut down or downsize aging rooms

- Reduce overall plant energy consumption by 20–30%

- Free up valuable floor space for production or logistics

From a carbon footprint perspective, these changes contribute meaningfully to sustainability goals and ESG reporting.

Faster Delivery, Lower Risk: A Supply Chain Advantage

Zero-aging technology also transforms how packaging operations fit into modern supply chains.

With traditional solventless lamination, quality issues such as insufficient peel strength may only become visible days after production. By then, entire rolls may need to be scrapped.

Zero-aging enables real-time quality verification, allowing operators to:

- Measure bond strength immediately

- Adjust parameters before large volumes are produced

- Avoid costly batch-level waste

At the same time, delivery time smooths down precipitously. Tasks that would have taken many days previously can now be carried out by the end of the working day, thus helping to cater quickly to express orders and small-scale production requests.

Traditional vs. Zero-Aging Solventless Lamination

From an operational standpoint, the differences are clear:

- Curing time drops from days to hours or less

- Energy consumption decreases significantly

- Food safety risks are reduced through faster chemical stabilization

- Production flexibility improves across the board

Rather than being a niche upgrade, zero-aging represents a structural improvement to solventless lamination workflows.

Why Zero-Aging Matters Looking Toward 2026

As environmental regulations tighten and food safety audits become more frequent, packaging companies face increasing pressure to deliver faster, cleaner, and safer solutions.

Zero-aging solvent free adhesive technology offers a rare combination of benefits:

- Environmental compliance without productivity loss

- Improved food contact safety

- Lower energy costs and carbon emissions

- Greater responsiveness to market demand

For converters investing in new solventless laminating machines or upgrading existing lines, zero-aging is quickly becoming a baseline expectation rather than a premium feature.

Final Thoughts

Solventless lamination began as an environmental improvement. With the emergence of zero-aging technology, it is evolving into a comprehensive solution for modern packaging challenges.

By combining advanced solvent free adhesive chemistry with high-performance solventless laminating machines, the industry is moving beyond the limitations of 72-hour curing cycles. The result is a packaging process that is not only greener, but also faster, safer, and better aligned with the realities of today’s supply chains.

In the years ahead, zero-aging will likely define the next standard of solventless packaging production.