Blogs

Why Film Delamination Happens and How Lamination Machines Solve It?

In flexible packaging and industrial film applications, delamination is one of the most common and most frustrating quality problems. A film that looks fine on the surface may start to peel, blister, or separate between layers during use. Once that…

EU PPWR 2025/40 Guide for Solventless Lamination Adhesives

Every manufacturer prefers solventless lamination adhesive as it is more suitable for eco-friendly food hybrid packaging. It is very environmentally sustainable as well as high-powered, leading to a preference for producers who wish to lower the levels of volatile organic compound…

Solventless Laminators in Pharmaceutical Packaging: Applications, Benefits & Trends

Decadently, the pharmaceutical packaging industry is experiencing a sea of change occasioned by stringent safety measures, growing sustainability outlooks, and the increased need for high performance flexible packaging. The solventless laminator is one of the most notable advances. Initially started for…

How Anti-Counterfeiting Packaging Protects Your Brands and Consumers?

In the context of an increasingly complex global supply chain, counterfeit products have no longer been a problem confined to a few industries. Domains such as cosmetics, food and beverages, medicine, and clothing accessories have all been affected to varying…

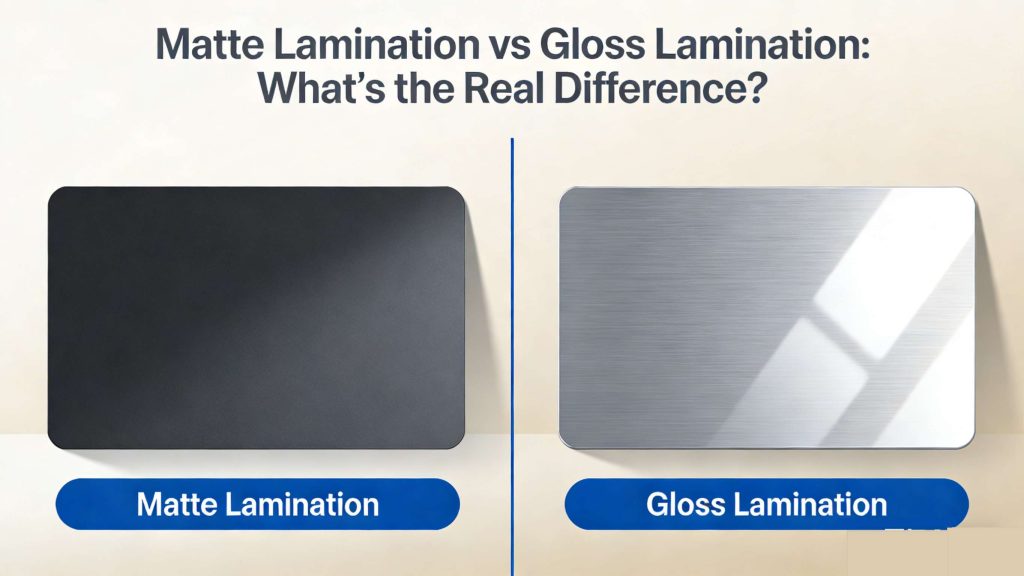

Matte Lamination vs Gloss Lamination: What’s the Real Difference?

In the printing and packaging industry, laminating is a common and important process. It not only protects paper and packaging materials from scratches, stains and moisture, but also enhances the overall visual effect, making the products look more refined and…

How Solvent Free Adhesive and Zero-Aging Technology Are Transforming Modern Packaging

In the last few decades, the packaging sector transitioned towards sustainability, food safety, and carbon mitigation. Abandoning the harmful substances in adhesive systems and applying the solventless laminating machines have been significantly helpful in reducing VOC emissions. However, the experience of…

What Is Soft Touch Lamination and Why It So Popular in Premium Packaging?

At first glance, many premium packages appear similar. They use muted colors, matte finishes, and minimal design. Yet once you pick them up, the difference becomes immediately clear. Some packages simply look refined, while others feel refined. That subtle tactile…

How to Choose the Right Solventless Lamination Machine: Single-Layer vs Multi-Layer

It is a major point to choose the most suitable solventless lamination machine for the packaging manufacturer who seeks to have productivity, quality, and sustainability all at the same time. As the interest in the eco-friendly solventless laminators with no VOC…